Whether you are a start-up or an experienced retailer, you must fulfill orders correctly because order fulfillment greatly affects the customer experience. Most customers usually expect their orders to arrive quickly and maintain high quality.

In this article, we’ll cover what order fulfillment is, the key steps in the order fulfillment process, the benefits of order fulfillment, and the best practices to follow when fulfilling.

What Is Order Fulfillment?

Order fulfillment, also known as order processing and fulfillment, is the step between receiving a new order and shipping the goods to the customer.

It includes processing the order, warehousing, packaging, and shipping the product.The order fulfillment process’s final goal is to accurately deliver the product to the customer on time.

In short, order fulfillment determines the delivery time to the consumer. Likewise, it determines a company’s ability to deliver in terms of quality.

Why Is Order Fulfillment Important?

Order fulfillment is one of the most important aspects of any sale. Whether you are B2B or B2C, the transaction is not complete until the customer receives being sold. Order fulfillment is how a company completes a sale and is at the heart of every business.

The way an order is fulfilled affects the customer’s buying decision. They want delivery and payment methods that meet their needs.

Therefore, it is best to analyze your customers’ expectations and needs beforehand. This analysis can help you gain a competitive advantage in your industry.

With the right order fulfillment process, you can:

- Reduce your shipping costs

- Have the right amount of product available all the time

- Prevent over-selling and under-selling

- Reduce overall operating costs

- Gain new customers, even international ones

- Provide better customer service and get better reviews

- Spend more time on actual business growth

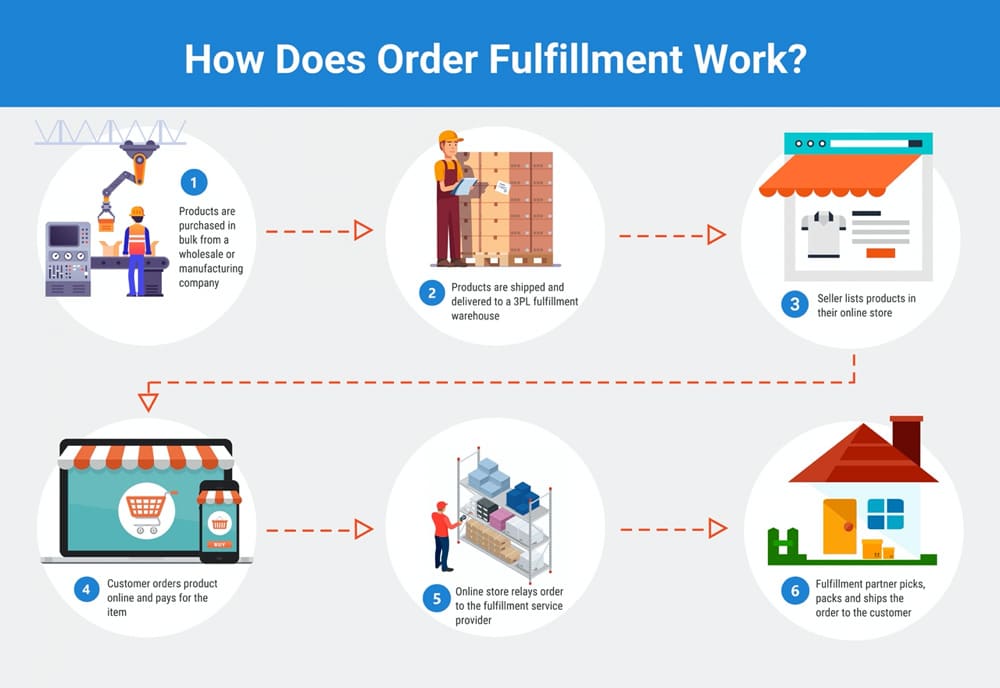

How Does the Order Fulfillment Process Work?

The order fulfillment process includes all steps associated with receiving, packing, and shipping customer orders. Depending on the products you sell and the size of your business, the process may include other steps.

Below are 6 key steps in the order fulfillment process:

Step 1. Receiving inventory

The first stage of supply chain fulfillment is receiving inventory from the supplier. In all cases, incoming inventory must be counted, inspected, and inventoried to ensure the right quantity and quality.

Step 2. Inventory storage

Once the fulfillment center receives the goods, they are inventoried and immediately released or sent to a short-term or long-term warehouse.

You should allocate products according to their popularity, placing the best-selling products closest to the packing table.

Step 3. Order processing

Once you have an order, start order processing. Your employees or designated third-party warehouse staff will automatically or manually pick the goods from the shelves.

Step 4. Packaging

Once all items in the order have been picked, it’s time to package them securely. Packaging materials are selected by the packaging team or automated fulfillment robots to protect your products and minimize actual dimensional weight.

Step 5. Shipping & delivery

Once everything is ready, the package can be shipped to the post office. You will then receive tracking information from the post office. Retailers can send customers shipping status updates to track their deliveries.

Step 6. Handling returns

If the customer decides to send back the product, you can start processing the return. Make sure every order you send out includes a return label so customers can easily put it on their package and send the item back without any questions or payment.

You may learn more on our blog for Fulfillment Services for details below:

Complete List 2022: Top 20 Best Fulfillment Services

What Are the Types of Order Fulfillment?

There are 4 main types of order fulfillment: in-house, third-party, dropshipping, and hybrid. Each model meets a specific business need.

1. In-house

By an in-house order fulfillment model, companies use their own employees to manage the fulfillment process. Employees handle all steps of the fulfillment process, including storing and shipping products on-site at a company-controlled location.

While this method gives you complete control over each step, there is an increased risk of surprises, and you get less opportunity and time to expand your business.

Therefore, this method is best used as a low-cost option for start-ups and established companies with end-to-end control over each operation.

2. Third-party

Third-Party order fulfillment means having a third-party logistics (3PL) or order fulfillment company take care of shipping, storage, and order/refund processing. Companies with insufficient storage space or personnel may choose this option.

In this case, the 3PL’s staff handles the entire fulfillment process, from receiving the manufacturer’s inventory to delivering the order to the end customer.

Inventory is stored in a warehouse controlled by the 3PL, meaning that companies using third-party fulfillment do not need to invest in their warehouse facilities.

Of course, there are drawbacks to working with third-party logistics. 3PL companies don’t know the product as well as you do, and they are likely to make more mistakes when they check returns or check for defects before shipping.

3. Dropshipping

Dropshipping is a more hands-off approach to manufacturing and order fulfillment. Similar to third-party order fulfillment, except there is no inventory to manage.

The order details are forwarded to the manufacturer when a customer orders and the product is shipped directly from the manufacturer to the end consumer. In the process, the retailer does not keep an inventory of the items.

The low barrier and minimal overhead make dropshipping an attractive option for many new e-commerce businesses. However, there is less control over the fulfillment schedule.

Since the transporter is responsible for the entire order fulfillment system, it is difficult for you to control the quality of service. Poor fulfillment provided by the manufacturer will result in a poor reputation for your brand.

4. Hybrid

A company that uses a mix of the above order fulfillment options is using a hybrid order fulfillment model. This option is best suited for companies needing more flexibility or undergoing rapid expansion.

In this model, a company uses a mix of the order fulfillment options described above. It can be implemented in different ways:

The company can handle the highest volume products in-house while outsourcing or dropshipping for lower volume products.

Or, the company can outsource inventory storage to a fulfillment center and ship it to other carriers while handling only product assembly or packaging.

The Benefits of Having an Order Fulfillment Process

Here are the most common benefits of the order fulfillment process:

1. Ensure on-time shipments

A smooth order fulfillment process allows you to prepare for all shipments and ensures that you have the correct amount of inventory and shipments on time.

This makes the company more reliable and leads to continued purchases from existing customers.

2. Provide delivery that meets customer needs

Some customers require certain specifications when ordering products, from budget to time constraints to product customization.

An effective order fulfillment process ensures that you meet all of their buying needs.

3. Gain a competitive advantage for your business

Many brands sell similar products to other brands, so your buying experience must stand out. A positive shopping and buying experience can make customers prefer your brand over others.

How to Improve Your Order Fulfillment?

Creating a streamlined order fulfillment process is the key to winning customers and maintaining a competitive advantage. There are some best practices to keep in mind that can help you optimize your order fulfillment process.

Here are 4 steps you can take to improve your order fulfillment process:

Step 1. Find the best-fit order fulfillment model

First, you need to use the best fulfillment model for your business. It should be flexible enough to handle your order volume, customer locations, and sales channels.

If you sell custom or made-to-order products, your fulfillment process must accommodate these complexities without unnecessary delays.

Step 2. Be careful about the location of your warehouse

The location where you ship your products is significant. This is an important aspect of your e-commerce fulfillment strategy. Customers expect products to be delivered quickly and at a reasonable price.

To ensure that you deliver according to your customer’s expectations, minimize the time it takes for your package to travel from your warehouse to your customer’s location.

This will result in reduced transportation costs, leading to more satisfied customers.

Step 3. Enhance end-to-end supply chain visibility

End-to-end supply chain visibility means monitoring the process from sourcing to shipping. Both retailers and suppliers should be able to view real-time inventory and fulfillment processes on the order management system.

This has many benefits, such as your suppliers seeing available inventory and SKU to supply accordingly. Supply chain visibility also improves customer service and customer satisfaction after shipment.

Step 4. Maintain good relations with shippers

Shippers play a big role in delivering products to your customers quickly. Hold regular meetings with your shippers and ask if there is anything you can do to make their job easier, such as delivering orders earlier in the day.

When things go well, let them know. These compliments go a long way toward building relationships.

How to Choose the Right Order Fulfillment Service?

There are 4 models that companies can choose from when deciding on an order fulfillment strategy; in-house, third-party, dropshipping, and hybrid.

Before making the right decision, you should look at the product, potential fulfillment options, and the fulfillment cost.

If you have the capability within your company, you can gain more control over operations and costs by handling fulfillment in-house.

If your company’s internal talent and resources are in the middle, you may choose a hybrid model that allows you to get some of the benefits of both worlds.

If fulfillment and logistics skills and resources are scarce, there are obvious advantages to choosing third-party fulfillment services. It allows your team to focus on producing and selling your product, often leading to more predictability.

When it comes to in-house fulfillment, you hire employees, own the warehouse, and must ensure that every order goes out without a hitch. When using third-party order fulfillment, many of these challenges are no longer an issue for you.

Order fulfillment needs to be a top priority for any eCommerce brand. Whether using a third-party fulfillment or in-house, your processes must be robust. Loyal customers are at risk if you don’t meet their expectations for speed.

You may learn more on our blog for Fulfillment Costs for details below:

Fulfillment Costs Explained: Everything You Should Know in 2022

What Are the Features of Order Fulfillment Software?

There are many options for order fulfillment software, but look for software with the following features:

1. Generate pick lists

When an order comes in, your fulfillment team will receive a list of products. If this is done manually, it will leave a lot of room for error. Stick with using the software that can automatically generate easy-to-read pick lists for your employees.

2. Adjust inventory levels

The best order fulfillment software should be inventory control software, which can track the inventory levels of your products and automatically deduct new orders.

This will give you greater insight into your inventory and allow you to plan for the best reorder points.

3. Track shipments

Provide accurate delivery estimates and tracking. Make sure the software you use can do this to keep those customers returning.

Order Fulfillment FAQ

1. What does it mean to fulfill status?

It simply means it is still in the order fulfillment process and has not yet shipped.

2. What does order complete mean?

It means the customer has received the goods, and the order is completed.

3. What is the order fulfillment rate?

The order fulfillment rate (or order complete rate) is the number of orders processed divided by the total number of orders.

Order fulfillment rate = total number of orders processed / total number of orders

4. Is order fulfillment rate the same as order logistics?

Order logistics is another way to describe the order fulfillment process. It refers to storing, packaging, and shipping inventory to customers after they order through your e-commerce site.

5. How can I improve my order fulfillment period?

Improve your order fulfillment period by leveraging supply chain technology. This minimizes errors and fast-tracks business operations during procurement, production, and delivery.

Order Fulfillment Conclusion

We’ve covered various types of order fulfillment and the best practices for improving it. Remember, there is no single fulfillment process that works for every business.

Therefore, finding the right process to meet your company’s needs and customers’ expectations is important.

Our goal is to streamline your fulfillment process and keep your customers happy. If you would like to learn more about order fulfillment, please leave a comment below.

We are Yansourcing, a leading sourcing agent in China. If you are looking for international trade but do not have any experience importing or customizing products from China, please do not hesitate to contact us!