Knowing the cost to make your products is very important. The cost of goods manufactured helps you understand production expenses. It also helps you set better prices and manage inventory well.

If you need expert help with sourcing and making products, Yansourcing can assist you. They have many years of experience and make the process easier. They help you save time and money with custom solutions. This can help you make better choices and stay ahead in your business.

Key Takeaways

Knowing COGM helps you control production costs better. It shows where you can save money.

Correct COGM calculations help set fair product prices. This ensures you pay expenses and make profits.

Including work-in-progress inventory is very important. It stops mistakes and keeps financial plans accurate.

Software tools make COGM calculations easier to do. They lower errors and track costs instantly for smarter choices.

Yansourcing gives expert help with materials and cost control. Their help can make production smoother and more efficient.

What is Cost of Goods Manufactured (COGM)?

Running a factory means knowing your production costs is crucial. Cost of Goods Manufactured (COGM) helps you understand these costs clearly. It shows how much it costs to make finished goods in a set time. Let’s explain it step by step.

Definition and Purpose of COGM

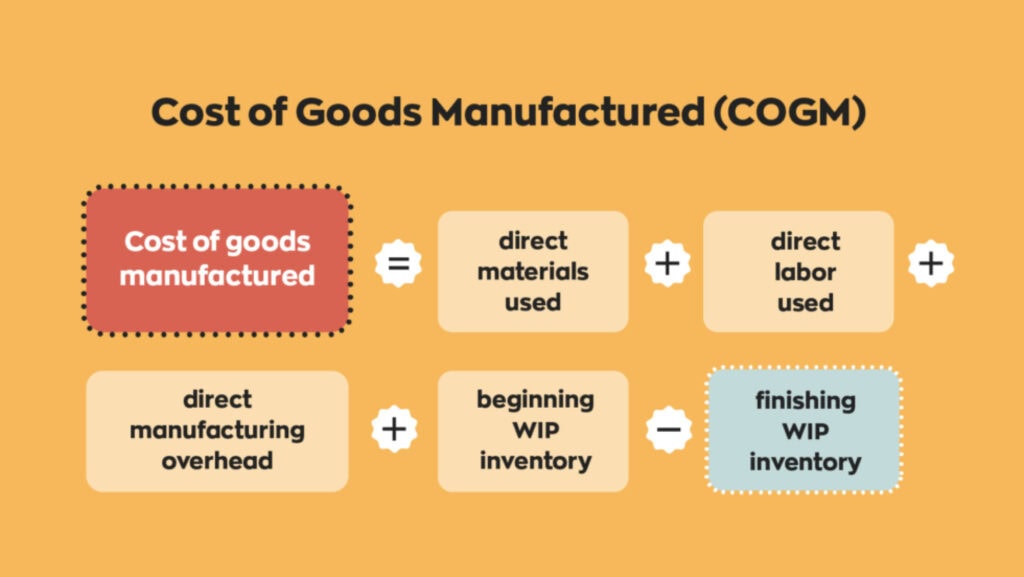

COGM is the total cost to make products ready to sell. It includes direct materials, direct labor, and manufacturing overhead used in production. Calculating COGM helps track costs and find ways to save money.

Why is this important? Knowing COGM helps you make better choices, like:

Improved Cost Management: You can control production costs better.

Enhanced Pricing Strategy: You can set prices that cover costs and earn profit.

Financial Planning and Analysis: It helps you plan budgets and predict future expenses.

Take Ford Motor Company as an example. They cut the price of their F-150 Lightning by $10,000. They did this by improving production and lowering costs. This shows how COGM helps with pricing and profits.

Key Components of COGM

To figure out COGM, you need to know its parts. These include:

Direct Materials: Raw items used to make products, like wood for furniture.

Direct Labor: Pay for workers who build the products, like carpenters.

Manufacturing Overhead: Costs like rent, utilities, and equipment wear.

Work-in-Progress (WIP) Inventory: Value of unfinished goods at the start and end of the period.

Here’s a simple table:

Component | Description |

|---|---|

Cost of Direct Materials | Raw materials used during the period, adjusted by inventory changes. |

Cost of Direct Labor | Wages paid to workers directly making the products. |

Cost of Manufacturing Overhead | Costs like rent, utilities, and equipment depreciation. |

Knowing these parts helps you calculate COGM and manage production costs better.

Role of COGM in the Manufacturing Process

COGM helps you see how efficient your production is. It tracks spending on materials, labor, and overhead. This detailed view lets you:

Spot areas to reduce costs.

Make smart choices about pricing and suppliers.

Handle supply chain problems confidently.

For example, a steel company studied their data and renegotiated supplier deals. This cut their costs by 10%, saving €1 million yearly. That’s the benefit of understanding COGM.

In short, COGM isn’t just a number. It’s a tool to improve efficiency, control costs, and set good prices. Learning this can help grow your manufacturing business.

Components of COGM

Knowing the parts of Cost of Goods Manufactured (COGM) is important. It helps you control production costs better. Let’s look at the main parts of COGM and how they affect your costs.

Direct Materials and Their Role in Costs

Direct materials are the raw stuff used to make products. For example, wood is used for furniture, and fabric is used for clothes. These materials directly change how much it costs to make things. Managing them well can save money and improve work. Tracking starting and ending work-in-process inventory shows how much material you use. Here’s a simple table to explain:

Component | Description |

|---|---|

Beginning Work in Process Inventory | Value of items being made at the start of a period. |

Total Manufacturing Costs | Costs from making goods, like materials, labor, and overhead. |

Ending Work in Process Inventory | Value of unfinished items at the end of a period. |

Direct Labor in Making Products

Direct labor means paying workers who make your products. This includes wages, taxes, and benefits like health insurance. Companies often use an hourly rate to estimate these costs. Direct labor also helps divide other costs, like overhead. To calculate it, you check the hourly rate, hours worked, and any cost differences. This helps keep your total costs under control.

Manufacturing Overhead and Its Importance

Manufacturing overhead includes indirect costs like electricity and fixing machines. Splitting these costs correctly is very important. It helps you set fair prices for your products. If you don’t do this right, you might price things wrong and lose customers. Properly dividing overhead helps you make better pricing and efficiency choices. This improves how much you save on production.

By learning about these parts, you can control costs better. This knowledge helps you improve your production process and grow your profits.

Adjustments for Beginning and Ending Inventory

When figuring out COGM, you must adjust for inventory changes. This ensures you only count costs for goods finished during the period. Let’s explain it simply.

At the start, there are unfinished goods called work-in-process (WIP) inventory. These are partly made items not ready to sell yet. Their value is added to the total manufacturing costs. At the end, there might still be unfinished goods. This ending WIP inventory is subtracted to focus on completed goods only.

Here’s an easy formula to remember:

COGM = Beginning WIP + Total Manufacturing Cost – Ending WIP

To make it clearer, here’s a table of key parts:

Component | Description |

|---|---|

Beginning Work in Process (WIP) | Value of unfinished goods at the start of the period. |

Total Manufacturing Cost | Total of direct materials, labor, and overhead costs during the period. |

Ending Work in Process (WIP) | Value of unfinished goods at the end of the period, subtracted from total. |

COGM Formula | Beginning WIP + Total Manufacturing Cost – Ending WIP |

Why is this important? Adjusting for WIP inventory avoids wrong cost estimates. If skipped, you might think you spent more or less than you did. This could cause pricing mistakes or bad financial plans.

Tracking WIP inventory gives a better view of production efficiency. It shows where you can save money or improve processes. These adjustments are key for managing costs and making smarter decisions.

How to Calculate COGM

Knowing how to figure out the cost of goods manufactured is important. It helps you manage production costs better. This section explains the steps, common mistakes, and how to use this knowledge with Yansourcing. By the end, you’ll know how to calculate COGM and make smarter business choices.

Step-by-Step Guide to the Cost of Goods Manufactured Formula

Calculating COGM can seem hard, but breaking it down helps. Follow these steps:

Gather Key Data

Collect all the needed information first. You’ll need beginning and ending work-in-process (WIP) inventory, direct materials, direct labor, and manufacturing overhead. These numbers are key for your calculation.Calculate Total Manufacturing Costs (TMC)

Add up all production costs for the period. This includes direct materials, labor, and overhead. For example, if materials cost $10,000, labor $5,000, and overhead $3,000, your TMC is $18,000.Use the COGM Formula

Apply the formula:COGM = Beginning WIP Inventory + Total Manufacturing Costs - Ending WIP InventoryFor example, if your beginning WIP inventory is $2,000, TMC is $18,000, and ending WIP inventory is $3,000, then:

COGM = $2,000 + $18,000 - $3,000 = $17,000Understand the Result

The result shows the total cost of finished goods ready to sell. It helps you see production spending and find ways to save money.

Follow these steps to understand your manufacturing costs clearly and make better decisions.

Common Mistakes to Avoid in COGM Calculation

Small errors can cause big problems in COGM calculations. Watch out for these mistakes:

Ignoring Inventory Adjustments

Forgetting to adjust for beginning and ending WIP inventory can mess up your numbers. Always include these values for accuracy.Misallocating Manufacturing Overhead

Overhead costs like rent and utilities must be divided correctly. If not, your product prices could be wrong.Using Incorrect Data

Check your numbers for materials, labor, and overhead carefully. Mistakes here can lead to wrong cost estimates.Skipping Regular Reviews

Costs change over time. Review your calculations often to keep them updated.

Avoiding these mistakes will save time and help you make smarter financial choices.

Practical Application for Building Materials with Yansourcing

Let’s see how COGM works for building materials with Yansourcing. Imagine you’re importing marble tiles for a project. Here’s how it helps:

Direct Materials

Yansourcing finds good-quality marble at fair prices. These material costs are a big part of your COGM.Direct Labor

If tiles need customizing, labor costs must be included. Yansourcing helps find skilled workers or factories for this.Manufacturing Overhead

Overhead includes costs like equipment repairs and utilities. Yansourcing ensures these costs are managed well.Inventory Adjustments

Yansourcing offers storage solutions to track inventory easily. This keeps your COGM calculations accurate.

Using Yansourcing makes sourcing and production easier. It helps you calculate and control your COGM better.

Example of COGM Calculation

Let’s use an example to make COGM easier to understand. We’ll go step by step to see how it works and why it’s important.

Detailed Example with Numbers

Imagine you own a factory making custom furniture. Here’s a cost breakdown for one month:

Cost Component | Amount ($) |

|---|---|

Direct Materials Used | 2,000 |

Direct Labor | 3,000 |

Manufacturing Overhead | 500 |

Beginning WIP Inventory | 1,000 |

Ending WIP Inventory | (500) |

Total COGM | 6,000 |

This table shows the main parts of your COGM. Now, let’s calculate it step by step.

Explanation of Each Step in the Example

Follow these steps to find the COGM:

Start with Beginning WIP Inventory

Write down the value of unfinished goods at the start. Here, it’s $1,000.Add Total Manufacturing Costs

Add direct materials ($2,000), direct labor ($3,000), and overhead ($500). This equals $5,500.Subtract Ending WIP Inventory

Take away the value of unfinished goods at the end, which is $500.Calculate Total COGM

Use this formula:COGM = Beginning WIP + Total Manufacturing Costs - Ending WIP

COGM = $1,000 + $5,500 - $500 = $6,000

Here’s a simple chart showing the cost breakdown:

Understanding the Results for Smarter Choices

The COGM of $6,000 shows how much it cost to make finished goods this month. This helps you:

Set Fair Prices: Knowing costs helps you price products to cover expenses and earn profit.

Find Ways to Save: If overhead is high, look for ways to lower it.

Manage Inventory Better: Accurate COGM helps avoid making too much or too little.

By knowing your COGM, you can control production costs and make better business decisions.

Why COGM Matters

Knowing the cost of goods manufactured (COGM) is very important. It helps you manage costs, set good prices, and handle inventory better. Let’s see how COGM affects these areas.

Managing and Cutting Manufacturing Costs

COGM shows you exactly what your production costs are. This helps you find ways to save money. For example, changing suppliers or improving production methods can lower costs.

Studies prove that cost-saving methods, like tracking activities and setting budgets, increase profits. Research shows these methods explain 79.1% of profit differences in small factories. By focusing on cost control, you can improve your profits and returns.

When you know your costs, you make smarter choices. You’ll spend wisely and increase your earnings.

Setting Prices for Building Materials

Correct COGM calculations are key for pricing products, especially in building materials. Pricing too high may lose customers, while pricing too low cuts profits.

Here are some ways manufacturing costs affect pricing:

Overhead costs, like utilities and quality checks, raise product costs.

Comparing actual costs to standard costs shows where you can improve.

Choosing job costing or process costing changes how you track costs and set prices.

By understanding these points, you can price your products fairly and still make a profit.

Helping with Inventory Management

COGM also helps you manage inventory well. It shows how much stock you need, so you don’t overstock or run out.

Here’s a table of important inventory measures:

Metric | What It Means | Example Formula |

|---|---|---|

Safety Stock | Extra stock to avoid running out and keep customers happy. | Safety Stock = Z X Standard deviation of demand X √L |

Inventory Turnover Ratio | How often you sell and replace inventory. | Inventory Turnover Rate = COGS / Average Inventory |

Days Sales of Inventory (DSI) | Average days to sell all inventory. | DSI = Average Inventory / COGS X 365 |

Gross Margin Return on Investment (GMROI) | Measures how profitable your inventory is. | GMROI = Gross Profit / Average Inventory Cost |

Using these measures, you can balance your inventory levels. This ensures you meet customer needs without wasting money on extra stock.

By understanding COGM, you can better control costs, pricing, and inventory. This knowledge helps your business grow and stay ahead of competitors.

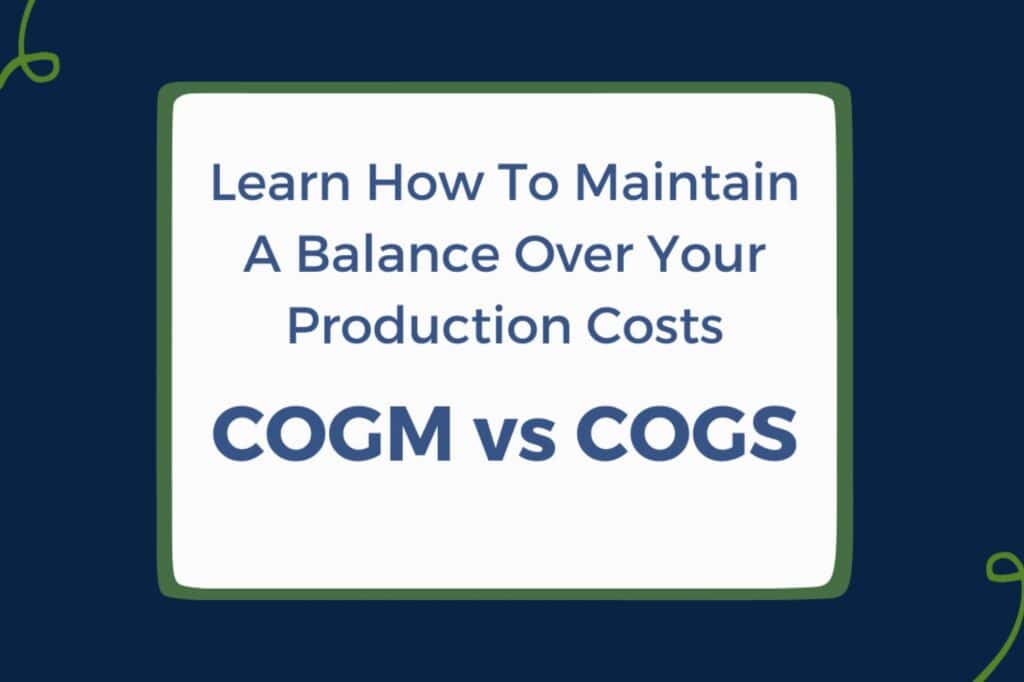

COGM vs. Cost of Goods Sold (COGS)

Knowing the difference between Cost of Goods Manufactured (COGM) and Cost of Goods Sold (COGS) is important. These terms are key in manufacturing but have different uses. Let’s explain them simply.

What is COGS?

COGS means the total cost of making goods you’ve sold. It includes direct costs like materials, labor, and overhead. But it doesn’t include marketing or office expenses.

Here’s what COGS covers:

Materials used to make sold products.

Pay for workers who made the sold goods.

Overhead costs like electricity and fixing machines.

Costs for packaging and shipping.

By calculating COGS, you see how much your sold goods cost. This helps you check profits and set fair prices.

How COGM and COGS Are Different

COGM looks at the cost of goods finished in a period. COGS focuses on the cost of goods sold. Here’s a simple comparison:

Metric | What It Means | What It Includes |

|---|---|---|

Cost of Goods Manufactured (COGM) | Manufacturing costs + Starting WIP inventory – Ending WIP inventory. | |

Cost of Goods Sold (COGS) | Total cost of goods sold during the period. | COGM + Starting finished goods inventory – Ending finished goods inventory. |

This difference matters because COGM tracks production costs, while COGS shows profits.

How COGM and COGS Work Together

COGM and COGS are connected in financial reports. COGM finds the cost of finished goods, which helps calculate COGS. Here’s how:

Use COGM to find the cost of goods made.

Add the starting inventory of finished goods.

Subtract the ending inventory of finished goods to get COGS.

This method ensures only sold goods costs appear in your income report. It shows your production costs and profits clearly.

By learning how these two work together, you can manage money better and make smarter choices.

Benefits of Knowing and Using COGM

Learning about the cost of goods manufactured (COGM) can change how you manage your business. It’s not just about numbers; it’s about making better choices to save money and work smarter. Let’s see how COGM can help you.

Smarter Money Decisions

COGM shows you exactly what your production costs are. This helps you make better financial decisions. For example, if costs are rising, you can find ways to lower them. It also helps you create accurate financial reports, which are important for planning. When you know your costs, you can make budgets that work and avoid surprises.

Here’s a simple table showing how COGM helps with money decisions:

Benefit Area | Description |

|---|---|

Cost Control | Shows where costs are rising or falling, so you can fix issues. |

Financial Reporting | Helps create accurate reports and plan future expenses better. |

Working More Efficiently in Manufacturing

COGM isn’t just about knowing costs; it helps you work better. By looking at your production process, you can find problems and fix them. For example, if labor costs are too high, you might try using machines or training workers better. COGM also helps you check how well your factory is working and make improvements where needed.

Benefit Area | Description |

|---|---|

Performance Evaluation | Checks how well your production is running and shows where to improve. |

Reaching Business Goals with Yansourcing’s Help

Yansourcing makes using COGM easier. They help you find good materials, manage inventory, and control costs. Their advice ensures your production matches your business goals. Whether you want to save money or work more efficiently, Yansourcing offers solutions that fit your needs.

By learning and using COGM, you can control your production costs and meet your goals. It’s a smart way to make your manufacturing better.

Tools and Best Practices for Simplifying COGM

Understanding COGM might seem tricky, but tools can help. This section explains software, tips for better data, and ways to use COGM daily. These ideas save time, cut mistakes, and control costs better.

Software Solutions for COGM Calculation

Software makes COGM calculations easier and faster. It reduces errors and tracks costs in real-time. This gives you accurate numbers when needed. Benefits of using software include:

Saves time by automating tasks.

Tracks costs live for better decisions.

Works with other systems to manage costs smoothly.

For example, tools like SAP or QuickBooks track materials, labor, and overhead. These programs give a clear view of costs, making COGM easier to calculate.

Tips for Accurate Data Collection in Manufacturing Costs

Good data is key for correct COGM numbers. Wrong data leads to bad choices. Here’s how to collect better data:

Keep It Consistent: Use the same way to track costs.

Use Smart Tools: Barcodes or RFID tags help track items easily.

Train Your Team: Teach workers to record data properly.

Accurate data shows true costs and helps find savings. This improves your production process.

Best Practices for Integrating COGM into Business Processes with Yansourcing

Adding COGM to your business can be simple. Yansourcing helps with suppliers, inventory, and cost control. Here’s how to make it work:

Set Clear Goals: Know if you want to save money or improve work.

Get Expert Help: Yansourcing offers custom solutions for your needs.

Check Often: Review your COGM numbers regularly to stay updated.

With Yansourcing, you simplify tasks and focus on growing your business. Their help ensures your costs match your goals.

Simplifying COGM is possible with the right tools, good data, and expert advice. These steps help you manage costs and make smarter choices.

Conclusion

Knowing the cost of goods manufactured isn’t just about math. It helps you control production costs, set better prices, and manage inventory wisely. By studying COGM, you can lower extra stock, improve cash flow, and find key cost factors to make smarter choices.

Yansourcing makes this even simpler. Their sourcing and manufacturing skills help you save money and work more efficiently. They offer custom solutions, like finding good suppliers or organizing inventory, to match your business needs.

Start using COGM now. It’s the first step to saving money and making smarter decisions.

FAQ

1. What’s the difference between COGM and COGS?

COGM shows the cost to finish goods in a period. COGS shows the cost of goods sold. Both help understand costs and profits but are used differently in reports.

2. Why does COGM matter for inventory?

COGM tracks production costs carefully. This helps avoid making too much or too little. Better tracking improves stock levels and cash flow.

3. How can I lower my COGM?

You can cut COGM by getting cheaper materials, working more efficiently, and lowering extra costs. Checking your process often helps find ways to save.

4. Can software make COGM easier?

Yes, tools like QuickBooks or SAP help with COGM. They collect data, track costs live, and reduce mistakes. This saves time and gives accurate numbers.

5. How does Yansourcing help with COGM?

Yansourcing finds good materials, manages stock, and cuts costs. Their help makes it easier to calculate and improve COGM for your business.