Finding a good manufacturer for your product in 2025 might seem hard, but it’s simpler than you think. Global trade is changing, giving businesses more tools and ideas on how to find a manufacturer that meets their needs. Did you know 85% of successful companies will use detailed supply chain data this year? This focus on accuracy helps you find a manufacturer that fits your requirements. Whether you choose local or overseas options, knowing trends like price-pack design—which grew by 52% in talks—can help you succeed. Let’s look at how to handle this process step by step.

Key Takeaways

Pick between local or foreign manufacturers based on your needs. Local ones are quicker for talking and shipping. Foreign ones may cost less for big orders.

Use websites like Alibaba or ThomasNet to search for makers. Always read reviews and ask for samples to check quality before deciding.

Go to trade shows to meet manufacturers in person. Bring questions to learn about their skills and make good connections.

Think about hiring sourcing agents like Yansourcing. They can help with language problems, check credentials, and make sure products are good.

Study manufacturers closely by asking for prices, checking certificates, and confirming their reputation. This lowers risks and helps you find trustworthy partners.

Types of Manufacturers

When finding a manufacturer, you’ll see two main choices: domestic or overseas. Each has its own pros and cons. Knowing these can help you pick the best option.

Domestic Manufacturers

Domestic manufacturers are based in your country. They’re great for fast communication and quick shipping. Visiting their factories is easier to check quality. Products made locally can attract buyers who like supporting local businesses or prefer “Made in [Your Country]” items.

But, domestic manufacturing can cost more. Labor and materials are pricier, which may lower your profits. For instance, in the U.S., areas like the Mountain West and Southeast rely less on global supply chains. Their tariffs range from 2-7%, making them good for some industries. Still, costs might be an issue.

Overseas Manufacturers

Overseas manufacturers, like those in China, India, or Vietnam, are known for being cheaper. They’re perfect for making large amounts of products at low prices. Many specialize in certain industries, improving your product’s quality.

However, working with overseas manufacturers can be hard. Language issues, cultural differences, and longer shipping times can cause problems. Some U.S. regions, like the industrial Midwest, face tariffs over 10%, raising import costs. But with a good sourcing partner, like Yansourcing, you can handle these challenges well.

Pros and Cons of Domestic vs. Overseas Manufacturing

Here’s a simple comparison to guide you:

Factor | Domestic Manufacturing | Overseas Manufacturing |

|---|---|---|

Cost | Higher labor and material costs | Lower production costs |

Quality Control | Easier to monitor | May require third-party inspections |

Shipping Time | Faster delivery | Longer lead times |

Communication | Easier due to proximity and language | Potential language and cultural barriers |

Tariffs | Minimal or none | May face higher tariffs |

Choosing between domestic and overseas manufacturers depends on your needs. If saving money and scaling up is key, go overseas. But if quality and fast delivery matter more, domestic might be better.

Research Methods for Finding a Manufacturer

Finding a manufacturer might feel tough, but good research helps. With the right steps, you can find reliable options. Let’s look at three easy ways to connect with manufacturers in 2025.

Using Online Directories and Platforms (e.g., Alibaba, ThomasNet)

Online directories are great for finding a manufacturer. Websites like Alibaba, ThomasNet, and Global Sources link you to many suppliers. These sites have filters to help you search by product type, location, or certifications. For example, if you need electronics, you can find manufacturers with ISO certifications for quality.

Here’s a simple comparison of two popular platforms:

Feature | Alibaba/Global Sources | ThomasNet/Kompass/Europages |

|---|---|---|

Database Size | Millions of supplier profiles and listings | In-depth manufacturer profiles |

Filtering Options | Advanced filters by category, location, etc. | Detailed company overviews |

Communication | Built-in messaging for direct contact | Customer references and reviews |

Verification | Cross-checked data for accuracy | Quality certifications like ISO standards |

User Feedback | User reviews on platforms like Trustpilot | Testimonials and user-generated content |

Always check reviews and ask for product samples. This ensures the manufacturer is trustworthy before you commit. Alibaba also offers trade assurance programs to protect your orders.

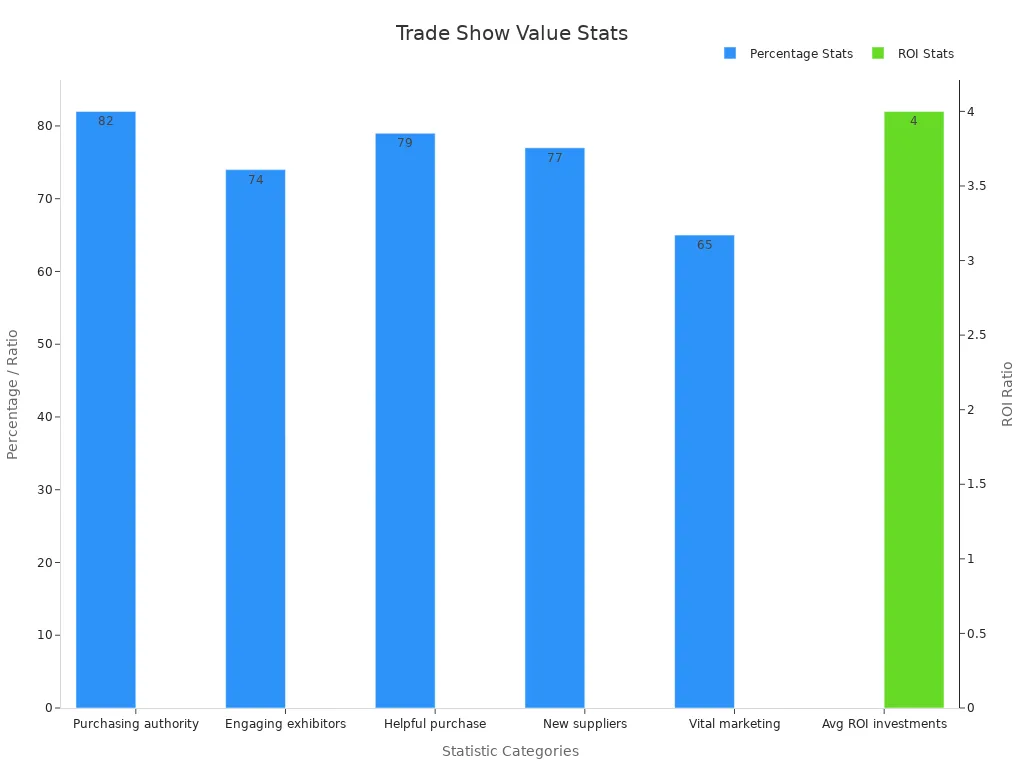

Attending Trade Shows and Industry Events

Trade shows are another smart way to find a manufacturer. You can meet suppliers, see samples, and build connections. Plus, you’ll learn about new trends in your industry.

Here’s why trade shows are helpful:

Statistic | Value |

|---|---|

Percentage of attendees with purchasing authority | 82% |

Attendees who believe engaging with exhibitors increases likelihood of purchase | 74% |

Attendees who find trade shows helpful in making purchase decisions | 79% |

Executive attendees discovering new suppliers | 77% |

Average ROI on trade show investments | 4:1 |

Businesses that consider trade shows vital to marketing | 65% |

Prepare questions for potential manufacturers before attending. Ask about their production speed, quality checks, and capacity. Collect business cards and follow up later to stay connected.

Leveraging Sourcing Agents like Yansourcing

If directories or trade shows seem hard, try a sourcing agent. Agents like Yansourcing help you find manufacturers, especially in places like China. They handle language and cultural barriers for you.

Yansourcing offers services like supplier checks, quality control, and shipping help. Here’s how they make sure you find the right manufacturer:

Metric | What It Means |

|---|---|

Product Defect Rate | Ensures low-quality products are minimized. |

On-Time Delivery Rate | Guarantees timely shipments to keep your supply chain running smoothly. |

Responsiveness & Resolution Time | Quickly addresses issues, ensuring reliability. |

Audit & Compliance Scores | Confirms manufacturers meet industry standards. |

Corrective Action Closure Rate | Tracks how effectively problems are resolved. |

Using Yansourcing saves time and lowers risks. They handle tasks like price talks and quality checks. This makes them a great partner for growing businesses.

Pro Tip: If you need electronics or toys, Yansourcing connects you with certified manufacturers.

Evaluating Manufacturers

After you’ve picked a few possible manufacturers, it’s time to check them carefully. This step makes sure they can provide the quality and dependability your product needs. Let’s break this into three simple steps.

Asking for Quotes and Samples

First, contact manufacturers to get quotes and product samples. This helps you see their prices and the quality of their work. A good manufacturer will give clear quotes showing material, labor, and shipping costs. They’ll also send samples so you can check their work closely.

Why is this important?

Manufacturers who give clear quotes and samples are more likely to become long-term partners.

Tracking how fast they respond shows how professional they are.

When you get a quote, check if all costs are listed. Are there any hidden fees? For samples, make sure they match your needs. If you use Yansourcing, they’ll handle this for you and connect you with trusted manufacturers.

Pro Tip: Use a checklist when reviewing samples. Look at material, durability, and finish. This makes comparing easier.

Checking Quality Standards and Certifications

Your product must meet high-quality standards. Make sure the manufacturer follows industry rules and has the right certifications. These prove they meet safety and quality guidelines.

Here are some tools used in quality checks:

Chart Type | Purpose | Example Use |

|---|---|---|

C Charts | Count defects per unit | Improving fabric quality in textiles |

U Charts | Track defects in different sample sizes | Checking manufacturing processes |

Control Limits | Spot unusual variations | Finding errors beyond normal limits |

Trends | See slow changes in processes | Watching for shifts in medical devices |

Patterns | Find repeating issues | Checking for high-low cycles in production |

Out-of-control Points | Spot strange patterns | Monitoring unusual production behaviors |

Ask about certifications like ISO 9001 for quality or ISO 14001 for the environment. For electronics, look for CE or FCC certifications. Yansourcing ensures their manufacturers meet these standards, saving you time.

Note: By 2024, testing and certification for consumer goods will reach $29.04 billion. This shows how important quality control is for top manufacturers.

Confirming Manufacturer Credentials and Reputation

Before signing anything, check the manufacturer’s background and reputation. This reduces risks like delays or poor-quality products. Start by asking for their business license. A trustworthy manufacturer will share this easily.

Also, check their history. How long have they been in business? Do they have experience making your product? Read reviews and ask for testimonials. If possible, visit their factory or request a virtual tour to see how they work.

Here’s some data about risks:

Statistic | Value |

|---|---|

Nonfatal injury rate (2020) | 3.1 per 100 workers |

Increase in nonfatal injuries (2020) | 20% rise from the year before |

Fatal injuries reported (2020) | 341 total |

Transportation-related fatal injuries (2020) | 77 total |

Positivity rate in manufacturing (2023) | 4.5% |

Positivity rate across all industries | 4.6% |

These numbers show why safety and ethics matter when choosing a manufacturer. Yansourcing can help check credentials and even do factory audits, giving you confidence.

Tip: Always ask for references from past clients. A good manufacturer will happily share them.

Negotiating Terms with Manufacturers

Talking about terms with a manufacturer might seem hard, but it’s important. This step makes sure your product is made just right. Let’s look at three simple parts to make this process easier.

Understanding Minimum Order Quantities (MOQs)

MOQs are the smallest number of items a manufacturer will make. These numbers depend on the product type and factory size. For example:

MOQ Type | Typical Range |

|---|---|

Low MOQ | |

High MOQ | Above 500 units |

If you’re new, find manufacturers with low MOQs. This lowers your upfront costs and risks. But remember, smaller orders may cost more per item. Talk openly with the manufacturer to agree on a fair deal.

Tip: Ask if first-time orders can have flexible MOQs. Many manufacturers adjust to build trust with new clients.

Negotiating Pricing and Payment Terms

Pricing talks can change how much your product costs overall. To get a good price, learn market rates and what affects costs, like materials or labor. Here’s how different methods can help:

Analysis Type | Purpose | Impact |

|---|---|---|

Compare the value of different choices. | Helps pick cost-effective and smart options. | |

Descriptive Statistics | Study market trends for better pricing ideas. | Sets fair and realistic price goals. |

When talking payment terms, ask for flexible options. Some manufacturers let you pay part upfront and the rest later. This helps manage money while ensuring the manufacturer gets paid.

Pro Tip: Use facts from your research to explain your price requests. Knowing average costs of similar products gives you an advantage.

Setting Clear Expectations for Deliverables

Clear rules about deliverables help meet quality and deadlines. Focus on measurable things like:

Defect rates: Track faulty items to ensure good quality.

Lead times: Confirm how fast orders will be ready.

Contract compliance: Make sure all agreed terms are followed.

You can also use a table to organize expectations:

Indicator Type | Description |

|---|---|

Delivery times | Ensure products arrive as scheduled. |

Quality indicators | Set clear criteria for product quality. |

Compliance with terms | Verify adherence to legal and ethical standards. |

Talk about these details before signing any contracts. A sourcing agent like Yansourcing can help with these talks and keep records.

Note: Regular updates from the manufacturer during production can help you spot and fix problems early.

Finalizing Production with Your Manufacturer

Keeping Track of Production Timelines

Sticking to production schedules is very important. It ensures your product is ready on time. Delays can mess up your plans and cost you money. To avoid this, talk clearly with your manufacturer and manage workflows well. Tools like live tracking and smart maintenance can help spot problems early.

Here’s how timelines are improving in 2025:

Evidence Type | Description |

|---|---|

Better planning removes delays and speeds up production. | |

Process Automation | Machines handle tasks faster, cutting down waiting times. |

Predictive Maintenance | AI tools predict and fix machine issues before they happen. |

Real-time Tracking | Tracks inventory and orders, making teamwork smoother. |

Good relationships with your manufacturer also matter. Regular updates and honesty keep everyone on the same page. This helps you handle changes quickly.

Tip: Use apps to track tasks and meet deadlines easily.

Setting Up Quality Control Steps

Quality checks make sure your product is good and safe. Start by agreeing on clear rules with your manufacturer. These can include checks before, during, and after production.

Here are some examples of quality checks by industry:

Industry | Quality Control Focus | Standards and Regulations |

|---|---|---|

Food and Drug | Testing for harmful chemicals or germs in products. | FDA, ICH |

Automotive | Checking parts for safety and proper fit. | SAE, NHTSA |

Electronics | Testing devices to ensure they work safely. | IEC, IEEE |

Aerospace | Inspecting every step to meet strict safety rules. | FAA, EASA |

For everyday products, watch for defects, success rates, and customer complaints. A manufacturer with strong quality checks saves you money and protects your brand.

Pro Tip: Work with Yansourcing to handle quality checks and meet rules.

Building a Long-Term Partnership with Yansourcing

Working closely with your manufacturer can lead to big success. Yansourcing helps by connecting you with trusted manufacturers. They take care of supplier checks and shipping, so you can focus on growing.

Here’s why Yansourcing is helpful:

They reduce defects and deliver on time.

Their team gives updates, so you always know what’s happening.

They help you get better deals and stay transparent.

By building trust and staying in touch, you can turn one project into a lasting partnership. This saves time and strengthens your supply chain for future needs.

Note: Partnering with Yansourcing helps you grow your business while keeping costs low.

Conclusion

Now you know how to find a manufacturer for your product in 2025. By following these steps, you can easily research, check, and partner with trusted manufacturers. Many businesses now focus on being eco-friendly and strong. Picking manufacturers who share these values can help you stay ahead. For instance, sorting suppliers by how reliable they are helps you choose the best ones. This makes your supply chain stronger and lowers risks from problems.

Start by using tools like Yansourcing. They make it simple to find the right manufacturer and check product quality. Always remember, talking clearly and doing proper checks are important for building lasting partnerships.

Tip: Choose manufacturers who match your quality and eco-friendly goals. This helps your product stand out in the market.

FAQ

1. How can I tell if a manufacturer is trustworthy?

Look at their certifications, reviews, and client feedback. Request product samples and visit their factory if you can. A sourcing agent like Yansourcing can check their background and do audits for you.

2. How should I negotiate with manufacturers?

Learn market prices first. Use facts to explain your offers. Ask for flexible payments and clear agreements. Yansourcing can help you get better deals and keep things fair.

3. Can I work with manufacturers who need high MOQs?

Yes, but it depends on your money. Some manufacturers lower MOQs for new clients. Yansourcing helps find suppliers with low MOQs, which is great for small businesses.

4. What should a manufacturing contract include?

Add timelines, quality rules, payment plans, and penalties for delays. Be clear about what you expect and legal requirements. Yansourcing can help write contracts to protect your business.

5. How does Yansourcing make sourcing easier?

Yansourcing checks suppliers, handles quality control, and manages shipping. They find reliable manufacturers, talk about prices, and ensure on-time delivery. Their help saves time and lowers risks.