Whether you are a buyer or seller, you should often see and hear MOQ. But not many people know what it means.

If you are not familiar with the MOQ meaning, you have come to the right place. This guide will explain what MOQ is, how it defines, and everything you need to know.

MOQ Meaning: What is MOQ?

MOQ Means Minimum Order Quantity.

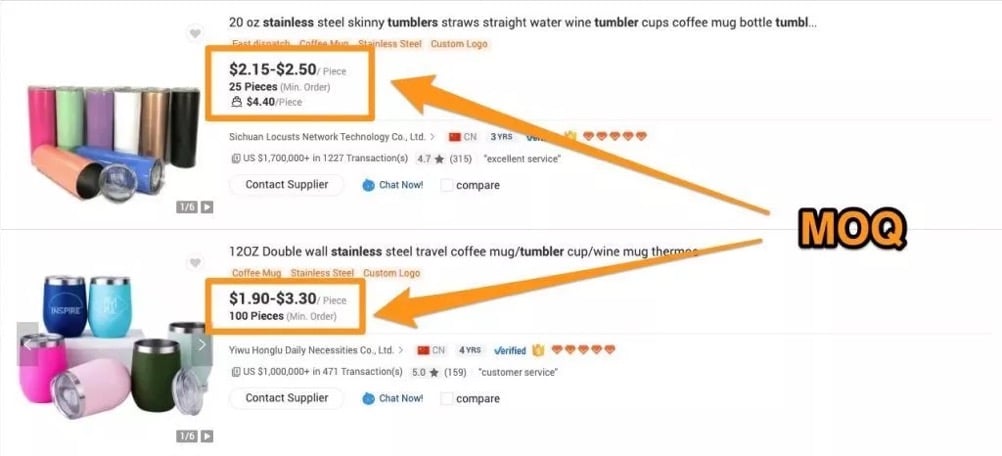

MOQ is an acronym for Minimum Order Quantity. When placing an order with some manufacturers and wholesalers, they may require a minimum order quantity (MOQ).

MOQ means that the customer must order a minimum quantity of the product before the company is willing to fulfill the order. Otherwise, sometimes they reject customers who are unwilling or unable to meet the minimum order quantity.

Thus, MOQ as a trade term is always used in the production by manufacturers or suppliers to help determine the minimum amount of product they are willing to supply or manufacture in an order.

Here is an example to better understand the MOQ meaning:

You walk up to a clothing manufacturer, discuss the price per dress, and decide to order 100pcs dresses in each style, but you don’t understand why the manufacturer insists that they can’t produce less than 200pcs dresses each at a time.

Yes, 200pcs dresses are their MOQ.

There is no set rule for MOQ, and there is no fixed MOQ. Each supplier and each type of business may have different settings.

Why Do Suppliers Set an MOQ?

To benefit the production plan, the supplier always sets a MOQ. Generally, the MOQ depends on the production costs, including labor, material, and machine operating costs.

With MOQ, suppliers can ensure that their production costs are covered, and a minimum profit is made.

Therefore, the supplier or manufacturer should consider all the costs in production, make an average cost, and calculate the production cost he needs to pay and the number of goods that will allow him to break even to determine the MOQ based on the production cost.

Some manufacturers have very low-profit margins, especially manufacturers in China. In General, Chinese manufacturers have a profit margin of 2% or 3% margins on bulk orders.

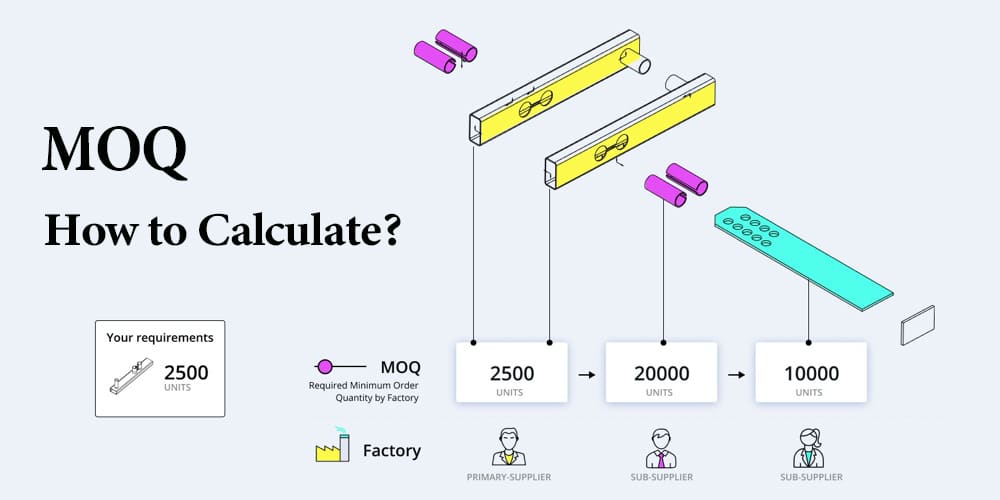

How to Calculate the MOQ?

There is no general formula for calculating MOQ, as many companies have different requirements. You can read the following steps as a starting point.

First, calculate your items’ average order value( AOV ) by dividing your overall revenue by the number of orders you receive at a given period. You have to set your MOQ above the AOV.

1. Consider the demand

Check on the historical data and forecast demand. If a supplier received an order for about 1000 units, it might not be feasible to implement a MOQ of 10,000 units suddenly.

Other considerations include seasonality and lead time, which takes time to produce an order.

2. Calculate the holding cost

How much will the supplier pay for the product in stock? The cost may vary for different products.

For example, some products need to be stored in the refrigerator or may have particular shapes, making inventory management more difficult.

So holding for an extended period is not an ideal method, and these costs need to be considered in the MOQ.

3. Find the break-even point

If a supplier sells 20 units at a fair market price, will that supplier make a profit? So what about 300 units?

By calculating all the indirect costs such as labor, setup costs, and other production and delivery costs, they will find the break-even point, which is important in determining the MOQ.

4. Setting the MOQ

After collecting all the data, set the MOQ for each product and develop strategies on how to implement it.

If necessary, volume purchase discounts and other incentives are the way to increase the average order value (AOV). Furthermore, work with customers to maintain relationships anywhere if possible.

MOQ Pros and Cons

MOQ has several significant advantages for both suppliers and buyers. If appropriately managed, MOQ can be an essential inventory control measure that can reduce costs for buyers and maintain profit margins for suppliers.

Pros for Suppliers

1. Improve cash flow

MOQ can help suppliers have healthier, more predictable cash flow when product prices and order sizes are well managed.

2. Reduce Inventory Holding Costs

In some cases, MOQ can control inventory costs. It can reduce reliance on warehouse space and inventory management.

With MOQ, suppliers will produce when there are buyers who order profitable quantities instead of making an order large enough and then looking for many smaller buyers to make a profit.

3. Gain Better Profit Margins

By using MOQ carefully, suppliers can better control their profit margins. The goods will be produced when there is a worthwhile profit.

Pros for Buyers

1. Economies of scale (volume discount)

Buyers usually know that they get the best price per unit when they work with suppliers with MOQ.

Sometimes, the savings from buying in bulk will bring more profit for the buyer – even when warehouse costs increase, or they have to sell at a discount to improve inventory turnover.

2. Improve Relationships with suppliers

It is essential to have a good relationship with raw materials suppliers. The relationship between the buyer’s Economic Order Quantity (EOQ) or desired inventory level to MOQ may be a delicate balance.

When MOQ exceeds EOQ, buyers can negotiate with suppliers about possible compromises or solutions, such as sharing orders with other buyers to get a lower MOQ.

Cons for MOQ

The main disadvantage of MOQ: It is challenging for small business owners and retailers.

Because if the MOQ sets high requirements for starting a transaction, many retailers may have to order unaffordable amounts of inventory to meet MOQ, which will drive upfront costs.

So it will be a very high standard for beginners or small business owners to place an order.

MOQ Types

Generally speaking, there are four main types of MOQ offered by suppliers or manufacturers:

1. Low MOQ

Low MOQ is in the range of 1 to 100 units. Most suppliers set this type of MOQ as startups just entering the industry and creating a niche.

Sometimes, low MOQ does not guarantee that they will break even, but they would rather suffer losses than lose potential customers.

2. High MOQ

Compared with low MOQ, high MOQ does not have a specific value. It varies with industry and product type.

However, please note that high MOQ only allows the top 20%~30% of stores to cooperate regardless of the industry.

For example, some manufacturers many buyers cannot purchase from because their MOQ limits many people and allows about 20-30% can be their customers. Those 20-30% of customers are usually the top large chain stores.

3. Simple MOQ

Most suppliers have to deal with at least a simple MOQ. It means that there is a single restraint on orders. This low-end limit can be a minimum spend or a minimum order quantity.

For example, a textile dyeing manufacturer may have a MOQ requirement. For most dyeing suppliers, it is not profitable to run machines just for dyeing fewer quantities of textiles, so they may require a MOQ to make the order profitable.

4. Complex MOQ

Instead of dealing with just one constraint, a complex MOQ has two or more requirements for an order.

For example, a home decor manufacturer requests the minimum quantity and other constraints such as minimum sizes for each color and type of material used, even how it is packaged, and the minimum dollar amount.

All of these conditions must be met before the buyer place an order.

What Influences MOQ?

There are two main factors when considering a supplier’s MOQ: Raw materials and order quantity:

1. Raw Materials

Material suppliers also have MOQ in their supply chain, just as wholesalers buy finished goods from their product suppliers.

For example, the material used to make a bottle only starts production when an order is received, and the order may have a MOQ.

Manufacturers do not store raw materials, and they usually purchase materials after receiving a product order.

For example, the resin material used to make resin balls is only purchased after the order is received, and then that order may have a MOQ.

Therefore, suppliers of resin balls need to consider the MOQ of resin material and any other components used in production when setting their resin balls’ MOQ for the buyers.

2. Order volume

Order volume is at the heart of MOQ. Suppliers need to find a balance point where orders generate profits for them. Before setting MOQ, suppliers should consider who they are selling to and who they want to sell to.

For example, if most customers are small retailers, the MOQ should be much lower than if the customer is a large chain store.

And the pricing of the product needs to be adjusted accordingly (e.g., a lower MOQ will have to have a higher price to ensure they can still realize a profit).

If suppliers typically sell low-margin or high-volume products, they may need a high MOQ to break even.

How to Make Maximize MOQ?

MOQ terms may seem unfriendly if you are on the buyer side, but they’re great when you’re a seller.

Regardless of which side you are on, here are some tips on handling MOQ:

1. Incentivize your orders with a higher cost

If you’re going into wholesale, you can ask for MOQ on bulk buyers to help ensure they pay you a minimum amount.

In exchange for the MOQ, you may offer an order volume discount, where you charge your customers a smaller unit price in exchange for higher total consumption.

2. Increase Inventory Turnover

Ordering excess inventory can inspire you to have a higher inventory turnover, which means there is pressure to sell your inventory faster because you are putting more cash upfront.

It doesn’t mean flash sales deplete inventory but find creative ways to attract and retain customers.

If the MOQ is too high, that can’t meet your business model or market, and you’d better look elsewhere. Otherwise, you’ll spend too much money on the products and storage costs that you may not be able to recoup.

3. Find another supplier or distributor

If your manufacturer has a higher MOQ than you want, you can always try to negotiate with them. It never hurts to try!

Suppose the manufacturer doesn’t make any concession and still requests a high order quantity for you.

You can consider working with a trading company or wholesale distributor because these middlemen buy in bulk from the manufacturer and resell to others.

4. Ask other questions

You can get creative in conversations with your manufacturers or suppliers.

Check if the manufacturer will allow you to “mix and match” or order several different products to meet MOQ instead of ordering the same units.

Ask the manufacturer if they have products left over from other customers’ cancellations or if they are in production for other customers so that you may add on that. So, you do not need to produce them from scratch.

5. Focus on relationships

It may be possible to get good terms first from the manufacturer, but it will become easier over time, especially when you have established a good relationship with them.

Think of it as a partnership, not a transnational relationship. If a manufacturer is not willing to work with you, they may be the wrong partner.

Be kind to others anyway since partnerships are very important, especially during the global pandemic.

How to Find Low MOQ Suppliers? How to Negotiate MOQ?

I would suggest choosing 3~5 or at least two suppliers to compare. Ask them the same questions and get their samples.

Usually, the supplier can provide samples. If the sample is not expensive, and even for free, you may get a sample by paying for the shipping freight only.

You can ask the supplier if they can return the cost of the samples after you place your order. Some suppliers are willing to return the cost of samples for you.

We want a low MOQ to control business risks and costs, especially new products. For example, will the product be popular in the market? Can this supplier consistently produce a quality product?

After checking every detail, you can negotiate the MOQ with the supplier.

Tips: Reducing the MOQ from 1000 to 500~800 pieces is reasonable, but probably not from 1000 to 100~200 pieces.

How to Negotiate MOQ?

Case: The MOQ we expect is 300 pieces. The supplier may not agree to a quantity of 200 pieces because it is lower than the required MOQ of 1000 pieces. You should conduct several rounds of negotiation to determine what MOQ is acceptable and its reasons.

First, you need to ask them to lower the MOQ. You can say this to them.

“I just need to do 200~300 pieces for the market test initially. We’ll do a big order next time if it goes well.“

Or

“The first order is a test order for quality, packaging, and service. We want to find a good supplier for a long-term relationship. Can you do the MOQ for us for 200~300 pieces?“

If the supplier says no, you can put it another way and say.

“We wasted money on the previous order. You know shipping costs are expensive for small orders, and we hope to make money on the next order.“

If the supplier insists on 1,000 pieces, we can know that the 1,000 pieces MOQ is true. Otherwise, the supplier would lose money, so they asked for the MOQ.

Then we should let the supplier know that they have a chance to make a lot of money on the following order. We are helping them sell this product.

So try to say.

“Our brand is very influential in this industry, and if we work together this time, your factory will be one of our suppliers for other products.“

Or, you can say something like this.

“We invest money in advertising, design, packaging, and photography. We think we have a big change and will have a bigger order next time.“

At this point, some factories will lower their MOQ more or less, say 800 pieces.

However, this is still much more than the expected 300 pieces. It would help if you asked the salesman to ask the manager/owner again and give them a deadline.

FAQ for Minimum Order Quantity (MOQ)

1. Why is MOQ so high?

Minimum Order Quantity, or MOQ, is often high because manufacturers need to sell a certain amount of goods to cover production costs.

Another reason is that there is a minimum quantity of units in the production process, and they try to profit from the MOQ of their raw material suppliers.

2. When should MOQ be implemented?

If you are a manufacturer, It is important to stabilize your margins and make it worth your while to produce by implementing MOQ terms and setting the MOQ by packaging or bundling to increase the average order value for the products sold in complete sets.

3. How do I find the MOQ?

There is no standard formula for calculating MOQ.

To determine whether the MOQ is right for your business, you must forecast demand, research your market, and calculate quantity discounts and inventory holding costs.

Then, you can decide on the MOQ which is right for your business.

4. What is the difference between MOQ and SPQ?

MOQ means Minimum Order Quantity, which is the minimum number of products that can be ordered.

SPQ means Standard Package Quantity, which is the minimum number of products that can be ordered in a package.

It is essential to have a clear concept of both MOQ and SPQ so that your buyers can easily place orders.

5. What is the difference between MOQ and EOQ?

Economic Order Quantity (EOQ) is an equation used to determine the ideal amount of inventory in your warehouse so you don’t spend too much on storage and don’t run out of products.

Minimum Order Quantity (MOQ) is the amount of product a supplier or seller requires a buyer to buy at one time.

MOQ allows a buyer to buy more inventory than they need at one time, causing them to fall far short of EOQ.

6. How to deal if you don’t need a large inventory?

Usually, new wholesalers always require a smaller quantity. In this case, they will not be able to afford an MOQ set by the manufacturer.

To deal with this situation is best to contact the manufacturer directly and provide an honest statement about the quantities you can afford.

MOQ Conclusion

The MOQ enables you to get a lower price, but let’s not kid ourselves. It is based on the large order quantities, that would be a problem.

Suppliers are more willing to work for profitable customers and may put other buyers ahead of you in the future. If you try too hard to lower the MOQ, the quality of the product may also be lower.

So, it is important to understand the MOQ meaning, which will allow you to focus on exactly what you expect and make everything go well.

To learn more now, contact Yansourcing at +86-15902071989 (Whatsapp) or email info@yansourcing.com.