If you’re building a product in 2025—whether a SaaS app, a piece of consumer hardware, or something hybrid like a connected device—clarity on Product Design (PD) vs. Industrial Design (ID) can make or break time‑to‑market, cost, and product‑market fit.

This guide lays out definitions, where the disciplines overlap, how they collaborate, when one should lead over the other, and how to hire effectively.

Key takeaway: neither discipline “wins” in general. They lead in different contexts, and the best outcomes come from deliberate collaboration.

Quick definitions (and misconceptions to retire)

- Product Design (PD): A holistic discipline focused on identifying problems/opportunities, aligning with business goals, researching users, shaping end‑to‑end experiences, and specifying solutions—often digital (UX/UI) but increasingly spanning physical touchpoints, services, and lifecycle strategy. For 2025 context, PD encompasses methods and deliverables from discovery (research, journey mapping) to delivery (design systems, specs, analytics). See the Interaction Design Foundation’s overview of lifecycle and circular approaches in its circular design topic (IxDF, ongoing) and guidance on creating design proposals (IxDF).

- Industrial Design (ID): A discipline centered on physical products, synthesizing form, ergonomics (human factors), usability, materials and finishes (CMF = color, material, finish), and manufacturability (DFM = design for manufacturability) to scale from prototype to mass production. The IDSA characterizes industrial designers as user‑ and context‑focused generalists, not “just stylists,” in its education paper “I’m an Industrial Designer. Who am I?” (IDSA).

Misconceptions to drop:

- “Industrial design is just styling.” In reality, ID deeply engages DFM, CMF, ergonomics, and manufacturing scale‑up; the IDSA education paper underscores this broader mandate.

- “Product design only means apps/UX.” PD spans research, business alignment, and delivery across digital and physical contexts; compare role scopes in the IxDF’s difference between Product and UX Designer.

Where PD and ID overlap—and where they don’t

Both PD and ID are human‑centered and iterative. They meet in discovery (user research, problem framing), experience goals, and usability.

They diverge in constraints: PD can ship reversible changes quickly; ID must navigate hard constraints like tooling, tolerances, certifications, and supply chain realities.

PD bread‑and‑butter deliverables

- Research plans, personas, journey maps, information architecture

- Wireframes, interactive prototypes, design systems/tokens, annotated specs

- Analytics and experiment plans (e.g., A/B tests)

- For spec quality and handoff, see NN/g’s guidance on creating design specs for development (Nielsen Norman Group).

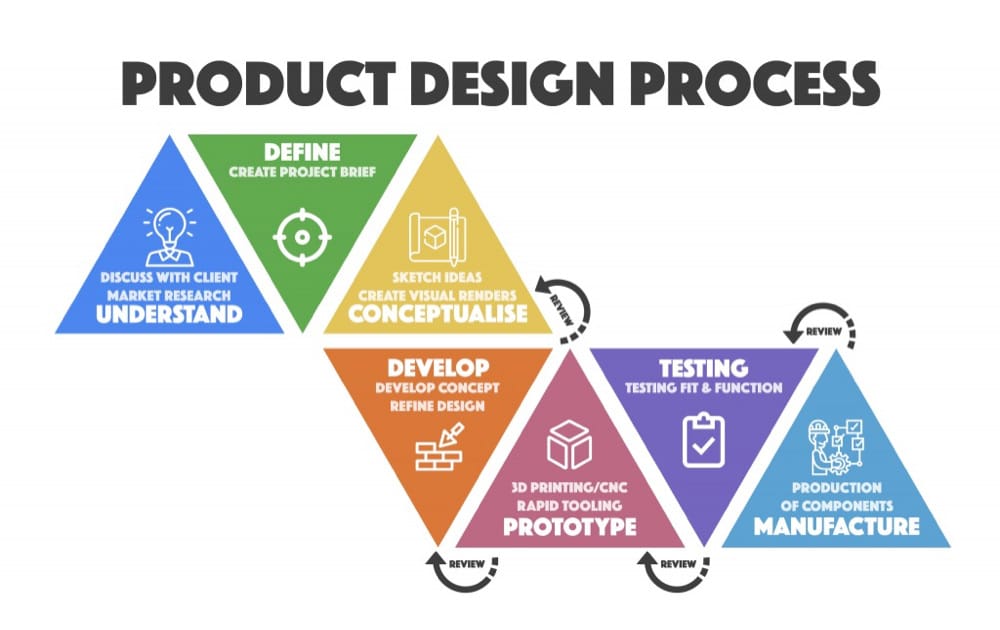

ID bread‑and‑butter deliverables

- Sketch explorations, CAD models (SolidWorks, Fusion 360, Creo, Alias)

- Looks‑like and works‑like prototypes (foam/clay, CNC, 3D prints)

- CMF decks, DFM notes, tolerance stack documentation

- Human factors studies, packaging/unboxing concepts

- For a process snapshot, see Core77’s explainer on an ID firm’s development phases in its process overview (Core77, 2024).

2025 toolchains and AI: what’s current

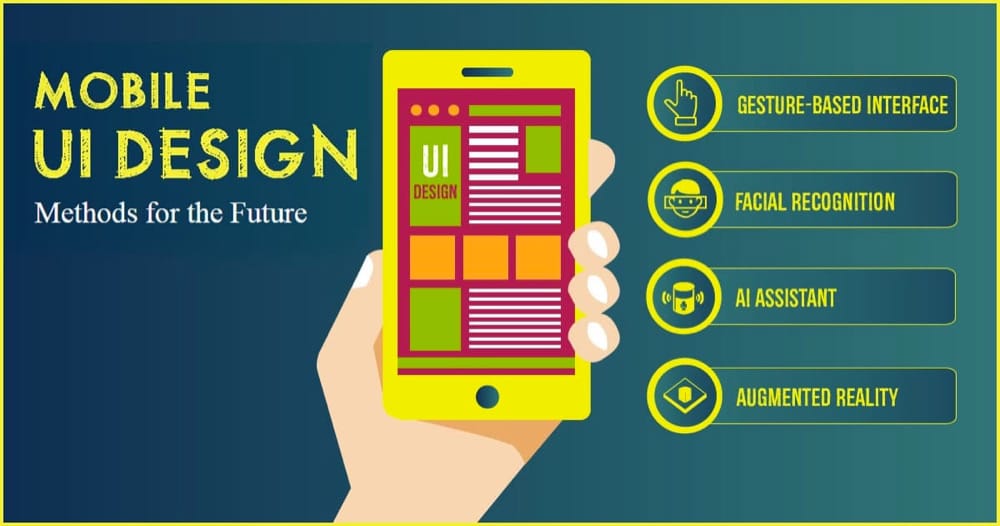

PD (digital)

- Design/prototyping: Figma, Sketch; collaboration: FigJam/Miro; delivery: Jira/Asana; analytics: Amplitude/GA; testing: Maze/UserTesting.

- AI enablement is increasingly baked into delivery pipelines; Atlassian described AI‑assisted workflows improving software delivery in its engineering blog on reinvented CI/CD (Atlassian, 2024) and highlighted adoption trends in the Forrester DevOps 2025 leader announcement (Atlassian, 2025).

ID (physical)

- CAD/modeling: SolidWorks, Autodesk Fusion 360, PTC Creo, Autodesk Alias; visualization: KeyShot/Blender; PLM/PDM: Siemens Teamcenter, PTC integrations; rapid prototyping: 3D printers/CNC.

- AI is entering CAD/PLM: Siemens announced AI copilot and manufacturability features in Solid Edge 2025 (Siemens) and described new AI‑enabled checks in NX 2025 updates (Siemens). Autodesk’s outlook on the sector is summarized in its Trends in Design and Make 2025 (Autodesk).

Lifecycle, time, cost, and risk: why sequencing matters

PD iteration cadence

- Digital teams operate in sprints (often 2–4 weeks) with continuous discovery and delivery. Iterative testing reduces the cost of late changes; see NN/g’s guidance on design risk management (Nielsen Norman Group).

ID phase gates (for hardware)

- EVT (Engineering Validation Test): early functional prototypes, initial debug; often on the order of weeks.

- DVT (Design Validation Test): refine for manufacturability, reliability, and compliance; tooling commitments rise, changes get expensive.

- PVT (Production Validation Test): pilot runs on final tooling/line; late changes are very costly.

- Manufacturing partners emphasize a design freeze before ramp and the escalating cost of change from DVT to PVT; see Flex’s perspective on scale challenges in its power/heat/scale article (Flex, 2024) and Jabil’s outlook on development cycles in its automotive development cycles blog (Jabil, 2024).

Certification and compliance (indicative ranges, vary by device)

- FCC Part 15 (US EMC/radio): approximately $5,000–$20,000+; see the overview in the SGS explainer on FCC approval (SGS, 2024).

- CE EMC and safety (e.g., IEC 62368‑1/UL): several thousand to tens of thousands; Intertek covers evolving requirements and RED cybersecurity in its RED cybersecurity series (Intertek, 2025).

- Emerging chemical/compliance fees (UK REACH) can affect BOM/COGS; see UL’s UK REACH fees update (UL, 2025).

Implication: front‑load ID to de‑risk irreversible decisions (tooling, certifications) and exploit PD’s ability to iterate quickly where changes are cheap (UX flows, onboarding, pricing tests).

Collaboration and handoffs in hybrid products (IoT, wearables, CE)

Shared artifacts to establish early

- Experience blueprint and system map: align physical, digital, and service touchpoints.

- Interface–enclosure integration reviews: align PD’s UI with ID’s form factor, sensors, ports, and ergonomics.

- Requirements traceability for regulated products: risk controls and usability files aligned across teams.

Typical collaboration model

- Early triad: ID + Mechanical Engineering (ME) + Electrical Engineering (EE) define feasibility envelope; PD leads digital flows and service experience.

- Supplier engagement: ID/ME consult contract manufacturers early for DFM feedback and lead‑time awareness.

- QA/compliance: ID coordinates with labs; PD ensures UX risk mitigations and documentation for audits.

For PD process hygiene and measurable UX, see NN/g on A/B testing (Nielsen Norman Group) and its UX benchmarking guidance (Nielsen Norman Group).

For quality systems and manufacturing assurance, refer to ISO’s quality management overview (ISO) and ASQ’s QA vs. QC primer (ASQ).

Decision guide: when PD leads, when ID leads, and when to co‑lead

Digital‑only SaaS/app

- PD leads. Focus on discovery → delivery loops, design systems, experimentation, and product metrics. ID is not required unless there’s a physical brand expression (e.g., peripherals, packaging for enterprise kits).

Pure physical consumer product (no app)

- ID leads. Emphasize ergonomics, CMF, DFM, packaging, and manufacturability. PD can contribute to service touchpoints (website, onboarding collateral, support flows).

IoT/Hardware + Software

- PD and ID co‑lead. Establish shared artifacts and synchronized milestones (e.g., enclosure lock for EVT vs. UX beta). Early alignment prevents UI–hardware clashes (screen size, button placement, sensor visibility, thermal constraints).

Regulated industries (medical, automotive)

- ID integrates compliance and documentation early (usability files, risk management). PD ensures traceability of UX requirements and risk controls. Plan buffer for verification/validation and external audits.

D2C hardware refresh (cost‑down or CMF variant)

- ID leads on cost/assembly simplification, CMF variants, and yield improvements. PD handles app updates, unboxing, retention loops, and communication of changes.

What “good” looks like: deliverables by discipline

PD exemplars

- User research brief → insights report tied to business goals

- Journey map with pain points and measurable success metrics (activation, retention)

- Clickable prototype with task‑level annotations and acceptance criteria

- Design system tokens and component specs aligned with engineering

ID exemplars

- Concept sketches exploring anthropometrics and brand language

- CAD assemblies with tolerance stacks and draft angles for injection molding

- CMF deck specifying pigments, textures, coatings, and durability tests

- DFM notes with part consolidation opportunities and assembly time targets

Cost and timeline signals: reading the risk

Signals to prioritize ID early

- Complex tooling (multi‑cavity molds), tight tolerances, structural loads

- High compliance burden (EMC, safety, cybersecurity), harsh environments

- New material/process adoption (e.g., magnesium die casting, LSR overmold)

Signals to prioritize PD early

- Ambiguous market fit or problem framing, new monetization models

- Multi‑platform UX complexity, service blueprint changes

- Heavy reliance on data‑driven optimization (pricing, onboarding)

Why changes aren’t equal

- Changing a corner radius post‑tooling may require steel re‑cut or new molds (weeks and thousands to hundreds of thousands of dollars), whereas updating a UI component can be shipped in a sprint. Manufacturers stress locking critical geometry before DVT/PVT; see Flex’s scale hurdles perspective (Flex, 2024).

Case snapshots: how approach changes outcomes

ID‑first reduces tooling risk and accelerates scale

- KAV Sports bicycle helmets used additive manufacturing and engineered materials to enable mass customization without traditional tooling, reducing per‑unit cost and speeding market entry; see the KAV Sports case study (Jabil, 2023) and material development in Jabil engineered materials news (Jabil, 2023).

Integrated PD–ID lowers complexity in regulated domains

- Automotive electronics programs combining design, software, simulation, and manufacturing reported complexity and cost reductions with faster time‑to‑market; see Jabil + AVL collaboration (Jabil, 2024).

Note: Vendor case studies can be promotional; treat them as directional rather than definitive.

Hiring guidance for founders and design leaders

Who to hire first?

- Digital‑only: Product Designer with strong discovery and UX/UI craft. Screen for research rigor, system thinking, and measurable outcomes. Use work samples aligned with NN/g‑style spec quality and risk management practices (Nielsen Norman Group).

- Physical‑only: Industrial Designer with strong DFM/CMF and collaboration history with ME/EE/CMs. Probe for tolerance/assembly fluency and certification planning.

- Hybrid IoT: A senior PD and a senior ID co‑foundational pairing. Establish shared rituals and a single owner for the experience blueprint.

Interview prompts

- PD: “Walk us through a decision where data contradicted intuition—how did you change the roadmap?” “Show a spec handoff that prevented rework.”

- ID: “Show CAD that changed after supplier DFM feedback—what was the impact on COGS?” “How did you plan for certification lead times?”

Compensation signals (U.S., directional 2023–2025)

- Web and Digital Interface Designers (SOC 15‑1255) reported a May 2023 median of about $108,820 according to the BLS OES page (U.S. BLS, 2023). “Product Designer” is not a unique SOC category; market rates (esp. in tech hubs) can be higher.

- Industrial Designers (SOC 27‑1021) show a national median around $81,870 in May 2023 per the BLS OES overview (U.S. BLS, 2023). Actual offers vary widely by industry and level.

- Aggregators show higher bands in tech; for instance, Indeed lists a U.S. average for Product Designers around 2025; see Indeed salary estimates (Indeed, 2025). Treat aggregator data as directional.

Metrics that matter

PD metrics (typical)

- Activation, retention, conversion, task success, time‑on‑task, SUPR‑Q/SUS; see NN/g’s resources on A/B testing (Nielsen Norman Group) and UX benchmarking (Nielsen Norman Group).

ID metrics (typical)

- Ergonomics/usability testing scores, field failure rate, scrap/rework, COGS vs. target, assembly time, warranty claims, and environmental footprint. For foundations, review ISO quality management (ISO) and ASQ’s QA vs. QC primer (ASQ).

Glossary (2025 quick explainer)

- DFM (Design for Manufacturability): Designing parts/assemblies to simplify production, improve yield, and reduce cost and defects.

- CMF (Color, Material, Finish): The visual/tactile specification for parts, affecting brand, durability, and manufacturability.

- EVT/DVT/PVT: Hardware validation stages—Engineering (function), Design (manufacturability/reliability/compliance), Production (pilot runs/final tooling and line).

- BOM/COGS: Bill of Materials / Cost of Goods Sold; core to profitability and pricing.

Practical checklists

PD kickoff checklist

- Clarify the business goal and leading metric (e.g., activation).

- Map target users and top tasks; draft a hypothesis backlog.

- Define decision cadence (experiment/week) and analytics instrumentation.

- Align on spec format and acceptance criteria with engineering.

ID kickoff checklist

- Confirm product requirements and constraints (regulatory, environmental, durability).

- Select likely processes/materials; start DFM conversations with suppliers early.

- Plan prototyping path (looks‑like vs. works‑like) and validation schedule.

- Draft CMF targets and ergonomic goals; define test methods.

FAQ and mythbusting

Is one discipline “more important”?

No. PD wins where market learning speed matters most; ID wins where manufacturing realities can’t be bent cheaply.

Can one person do both?

In small teams, hybrids exist, but expect tradeoffs. For complex IoT or regulated products, separate specialists collaborating tightly is safer.

How early should suppliers be engaged?

As soon as core processes/materials are in view; early DFM feedback prevents costly changes later (DVT/PVT).

Is sustainability part of PD or ID?

Both. IxDF’s circular design lens (IxDF) applies to physical and service components; ID operationalizes it via materials/process choices, PD via lifecycle and experience decisions that drive behaviors (repair, reuse).

Action steps by audience

Students and early‑career designers

- If you love systems, research, and measurable UX impact, explore PD depth (don’t ignore basic hardware literacy). If you’re drawn to form, materials, and human‑object interaction at scale, pursue ID (build DFM and CAD rigor). Portfolio tip: show process, constraints, and outcomes.

Founders and PMs

- Map your product type to the decision guide. Hire the lead discipline accordingly and establish shared artifacts (experience blueprint, system map). Budget for certification and tooling if hardware is involved; plan PD experiments early for market risk.

Cross‑functional leaders

- Define handoffs and owners for specs, CMF, DFM, and analytics. Schedule interface–enclosure reviews and compliance checkpoints. Track the right metrics for each discipline and make tradeoffs explicit.

Bottom line: In 2025, the smartest teams make PD and ID co‑architects of the user experience, choosing which discipline leads based on the product’s dominant risk—market learning versus manufacturing constraints—and aligning their workflows to turn those risks into advantages.