Quality inspection is crucial in manufacturing. It ensures that products meet regulations and standards. Consider providing customers with a product that exceeds their expectations—that’s the power of effective quality inspection. Identifying issues early saves costs and safeguards your brand’s reputation. Research indicates that quality inspections enhance customer satisfaction by aligning products with their desires. This, in turn, fosters customer loyalty. Utilizing tools like trend tracking can prevent problems before they arise, making your operations more efficient and streamlined.

Key Takeaways

Quality checks make sure products meet rules and customer needs. This builds trust and keeps customers coming back.

Checking before, during, and after production finds problems early. This saves time and cuts costs.

Using good tools like samples and checklists makes checks better and faster.

Training often and having clear goals help teams do great work and improve.

Sharing results and fixing problems creates a strong focus on quality and doing things well.

Understanding Quality Inspection in Manufacturing

What is Quality Inspection?

Quality inspection checks if products meet rules and standards. Think of it as a checkpoint to catch problems early. In factories, this means checking materials, watching production, and reviewing finished items. The aim is to make products that match customer needs and follow rules.

There are three main types of inspections in manufacturing. Each type has a special purpose:

Type of Inspection | Purpose |

|---|---|

Pre-Production Inspection | Check raw materials for quality before making products. |

In-Process Inspection | Spot mistakes during the production process. |

Final Quality Inspection | Confirm finished products meet rules before shipping. |

These inspections check things like how well products work, how strong they are, and if they follow industry rules. Doing these checks helps make sure products are dependable and consistent.

Why is Quality Inspection Important for Product Excellence?

Quality inspection is key to making great products. It’s not just about finding mistakes—it’s about earning trust and adding value. By focusing on inspections, you ensure your products meet customer needs and shine in the market.

Here’s why it’s important:

Brand Reputation: Good products improve your brand and keep customers loyal.

Cost Reduction: Fixing problems early saves money on repairs and waste.

Competitive Advantage: Reliable quality helps you beat competitors.

Product Consistency: Regular checks make sure all items are equally good.

Studies show that careful inspections improve manufacturing results. For instance, using tools like ANOVA helps find and fix process issues. This method stops problems and supports ongoing improvements, ensuring better products over time.

By focusing on quality inspection, you don’t just meet rules—you go beyond them. This builds trust, keeps customers, and ensures every product is excellent.

Types of Product Quality Inspections

Pre-Production Inspections: Building a Strong Start

Pre-production inspections stop problems before they begin. These checks happen before making products. They focus on materials, parts, and setups. Think of it like checking ingredients before cooking. You want everything fresh and ready.

During these inspections, you ensure materials meet your needs. You also confirm suppliers understand your expectations. This step avoids big mistakes later. For example, if steel isn’t strong enough, you catch it early. This saves time and prevents bad products.

Tip: Always write down results during pre-production checks. This helps track suppliers and keeps them responsible.

In-Process Inspections: Watching While You Work

In-process inspections check quality during production. It’s like fixing mistakes as they happen. You don’t wait until the end to find problems. Instead, you check each step to stay on track.

These checks focus on processes, tools, and unfinished items. For example, if making furniture, you might check chair frames before adding fabric. This catches issues like loose parts or wrong cuts.

In-process inspections also spot patterns. If a machine makes uneven parts, you can fix it fast. This saves time and reduces waste.

Note: Regular in-process checks make work smoother and stop unnoticed mistakes.

Final Inspections: Checking Before Shipping

Final inspections are the last step to ensure quality. These checks focus on finished products. You make sure they work, look good, and meet standards.

For example, if making electronics, you test devices to see if they turn on. You also check for scratches and correct packaging. This ensures customers get what they expect.

Final inspections include pre-shipment checks. These confirm the whole batch is good before leaving. It’s like double-checking your bag before a trip—you want no surprises.

Reminder: Final checks protect your brand by sending only great products to customers.

Specialized Inspections: Safety, Environmental Compliance, and More

Specialized inspections go deeper than regular checks. They focus on areas like safety, environmental rules, and specific industry needs. These checks make sure your products meet special rules. This protects users, nature, and your business image.

Safety inspections stop accidents. They check if products are safe to use. For example, if you make electrical items, you test for overheating or bad wiring. These checks prevent recalls and keep people safe.

Environmental checks focus on being eco-friendly. They ensure materials and processes follow green laws. For instance, if you make packaging, you check if it’s recyclable or free of harmful stuff. These checks show you care about the planet, which customers like.

Industry-specific checks handle special needs. In construction, you might test materials for strength or fire safety. In food production, you check for contamination. These checks make sure your products meet your industry’s rules.

Tip: Specialized checks often need experts. Working with pros or outside agencies can make things easier and more accurate.

Adding specialized checks to your quality process covers everything. You protect customers, follow rules, and build trust in your brand. These checks aren’t just about meeting rules—they help you go above and beyond.

Step-by-Step Process for Conducting Quality Inspections

Step 1: Set Clear Quality Standards

Before starting inspections, decide what “quality” means for your product. These standards are like a guide, helping everyone stay on the same page. Without them, inspections can feel random and unclear.

First, figure out the rules your product must follow. These might include industry standards like ISO 9000 for managing quality or GMP for making products correctly. For research items, GLP ensures accurate data.

Quality Standard | What It Does |

|---|---|

ISO 9000 | International rules for managing and assuring quality. |

GMP | Ensures products are made the same way every time. |

GLP | Keeps research data accurate and trustworthy. |

Why do these rules matter? They make customers happy, keep you following laws, and improve inspections. For example, setting clear testing rules avoids confusion. When everyone knows the goals, inspections work better.

Tip: Write down your quality rules clearly. This helps your team and inspectors avoid mistakes and work more efficiently.

Step 2: Create a Detailed Inspection Plan

After setting standards, make a plan for inspections. Think of this as a step-by-step guide to catch problems early. A good plan keeps things organized and prevents bigger issues later.

Your plan should include:

How often to check products (sampling frequency).

When to adjust tools for accurate results (calibration schedules).

Steps to test products for strength and function (testing protocols).

Ways to sort and fix problems (defect classification).

Tracking materials from start to finish (traceability requirements).

Use tools like SPC and Pareto Analysis to improve your plan. SPC watches for changes in production, while Pareto Analysis finds the biggest causes of defects.

Statistical Tool | What It Helps With |

|---|---|

Statistical Process Control (SPC) | Tracks production changes to meet quality goals. |

Root Cause Analysis (RCA) | Finds the main reasons for quality problems. |

Pareto Analysis | Focuses on the biggest issues causing defects. |

Regression Analysis | Studies how different factors affect quality. |

Fishbone Diagrams | Looks at possible causes of problems in different areas. |

Note: A strong plan doesn’t just find problems—it stops them. Use tools like Fishbone Diagrams to spot and fix issues early.

Step 3: Choose the Best Tools and Methods

The tools and methods you pick are key to good inspections. The right ones make inspections faster and more accurate, saving money and time.

Start with the 5 Core Quality Tools: APQP, PPAP, FMEA, MSA, and SPC. These tools help stop mistakes before they happen. For example, FMEA finds possible failures, and SPC checks production to keep it steady.

Manufacturer Type | |

|---|---|

Best Manufacturers | ~1% |

Subpar Manufacturers | 5% or higher |

Advanced tools like digital calipers, spectrometers, and automated systems can improve accuracy. These tools help inspectors measure, test, and ensure products meet quality rules.

Reminder: Pick tools that match your product needs. Good tools lower mistakes and improve product quality.

By using the right tools and methods, you’ll build a strong inspection process that works every time.

Step 4: Conduct Thorough Inspections

Now it’s time to start checking your products carefully. This step puts your plan into action. You make sure every product meets your quality rules. Inspections aren’t just about finding mistakes. They confirm everything matches what you expect.

Here’s how to inspect properly:

Follow Your Inspection Plan

Stick to the plan you made earlier. Check each product or batch using your set rules. Test things like strength, size, or how well they work. Cover every step without skipping anything.Use the Right Tools

Use the tools you picked before. For example, use multimeters to test electronics. For furniture, use rulers and weight testers. Good tools make inspections faster and better.Inspect in Stages

Break inspections into smaller steps. Start with raw materials, then check during production, and finish with final checks. This helps catch problems early and avoid surprises later.Document Everything

Write down what you find during inspections. Use lists or software to keep track of results. These records help you spot patterns and prove your products meet rules.

Tip: Take your time during inspections. Careful checks ensure nothing is missed.

Step 5: Record and Analyze Inspection Results

Writing down inspection results isn’t just about keeping notes. It helps you find ways to improve. Looking at these results shows patterns that can fix problems.

Here’s how to handle this step:

Organize Your Data

Keep your records neat and easy to find. Use spreadsheets or special software to save inspection details. Include things like defect types, how often they happen, and which batches are affected.Look for Trends

Study the data to find repeated problems. For example, if one machine keeps making mistakes, it might need fixing. Finding patterns helps you focus on solving the main issues.Share Insights

Show your findings to your team. Use charts or graphs to make the data simple to understand. When everyone knows the problems, it’s easier to work together on solutions.

Note: Regularly studying results turns inspections into ways to improve quality.

Step 6: Address Non-Conformities and Implement Corrective Actions

Even with good inspections, problems can still happen. The key is to fix them quickly and correctly. This step stops small issues from becoming big ones.

Here’s how to handle problems:

Identify the Cause

Find out why the problem happened. Was it bad materials? A machine mistake? Or a missed step? Knowing the cause helps stop it from happening again.Take Immediate Action

Fix the issue right away. If a batch fails, repair or replace the bad items. If a machine breaks, fix it before making more products.Update Your Processes

Change your steps to avoid the same problem later. For example, if a supplier sends bad materials often, switch to a better one.Monitor the Changes

Watch the updates you made. Do follow-up checks to make sure the fixes are working.

Reminder: Fixing problems isn’t just about repairs. It’s about making your process stronger and more reliable.

Step 7: Share Results and Keep Improving

Sharing results is more than just writing them down. It’s about using inspection data to make your factory better. When you share findings clearly, your team can make smarter choices and improve over time.

How to Share Inspection Results

Organize Data Simply

Arrange your inspection results neatly. Use charts or graphs to show the data clearly. For example, pie charts can show defect types, and bar graphs can show trends. These tools help your team see problems and find solutions faster.Focus on Big Problems

Don’t include every small detail. Highlight the most important issues. If one machine causes most defects, make fixing it a priority. Tools like Pareto Analysis can help you find and fix the biggest problems first.Suggest Clear Fixes

Sharing results isn’t just about showing problems. Offer simple steps to solve them. For example, if materials fail checks, suggest changing suppliers or improving standards. Clear advice helps your team act quickly.

Tip: Keep reports short and clear. A summary works better than long pages of data.

How to Keep Improving

After sharing results, take action. Improvement isn’t a one-time thing—it’s a process that keeps your factory running better.

Set Clear Goals

Use inspection results to set goals you can measure. For example, aim to lower defects by 20% in three months. Goals give your team something to work toward and track progress.Work Together

Improvement works best when everyone helps. Share findings with your team and ask for ideas. Their experience can lead to smart solutions you might miss.Check Changes Often

After making improvements, watch how they work. Do follow-up checks to see if things are better. Celebrate success if defects drop. If problems stay, try new fixes.Use Technology

Digital tools can make improvement easier. Software can track changes, study trends, and give updates fast. These tools save time and improve accuracy.

Reminder: Improvement isn’t about being perfect. It’s about getting better step by step. Small changes add up to big results.

Why Sharing and Improving Matter

When you share results and focus on improvement, your factory gets stronger. Products improve, processes run smoother, and customers stay happy. Quality checks aren’t just about finding mistakes—they’re about building a better factory.

Tools and Techniques for Quality Control Inspections

Using the right tools and methods improves product quality. They help make work faster, reduce mistakes, and keep things consistent. Let’s look at some useful ways to improve your quality checks.

Statistical Sampling Methods for Better Inspections

Sampling methods are very helpful in quality checks. Instead of checking every product, you inspect a smaller group to save time. But how do you pick the best method? Here’s a simple guide:

Description | Advantages | |

|---|---|---|

Acceptance Sampling | Decide if a batch is good or bad without checking all items. | Saves time and avoids accepting bad products. |

Random Sampling | Pick items randomly so each has an equal chance. | Gives fair and accurate results. |

Stratified Sampling | Divide items into groups and check samples from each. | Makes results more precise by focusing on smaller groups. |

Systematic Sampling | Choose items using a set pattern or interval. | Quick and easy, but works best if there are no repeating patterns. |

For example, if you have 10,000 items, random sampling ensures every item could be picked. This method gives fair results. Stratified sampling works well if your items are in groups, like different sizes or materials.

Tip: Use systematic sampling for quick checks. Just make sure your process doesn’t repeat patterns that could affect results.

Picking the right sampling method helps you save time while staying accurate.

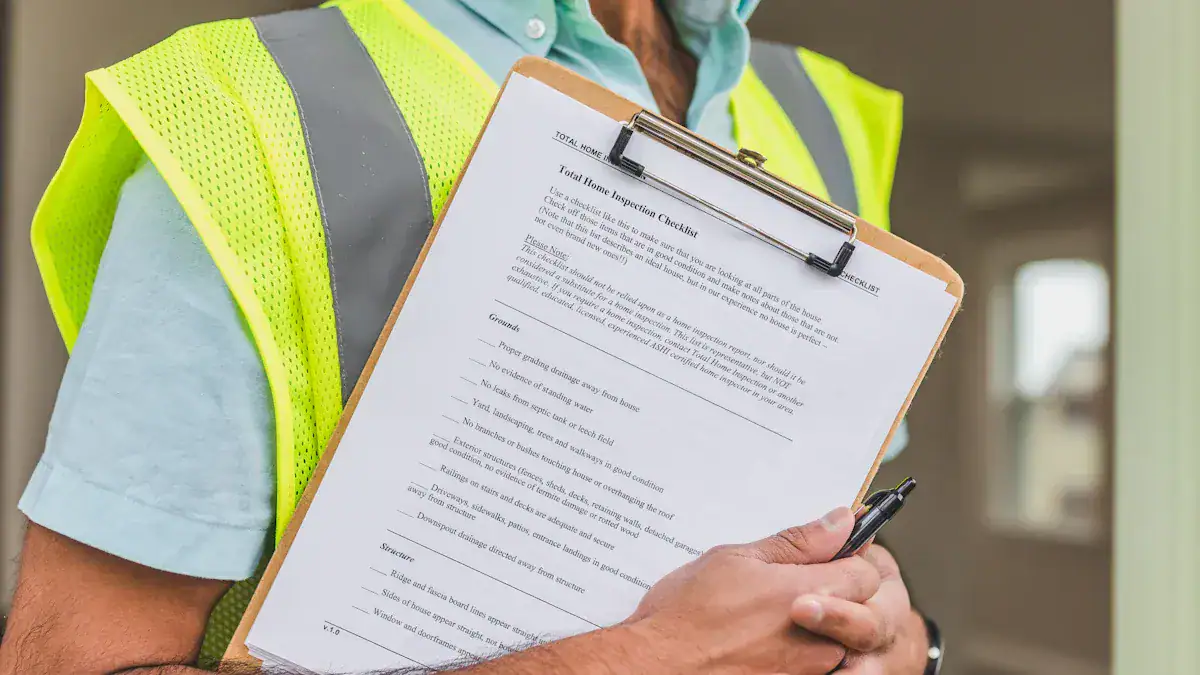

Checklists and Standard Operating Procedures (SOPs)

Checklists and SOPs are key to good quality control. They make sure tasks are done the same way every time. This reduces mistakes and keeps standards high. Think of them as a guide to doing things right.

Why they matter:

Consistency: Tasks are done the same way each time.

Fewer Mistakes: A clear plan helps avoid errors.

Time-Saving: You can quickly see what’s done and what’s not.

Responsibility: Everyone knows their job.

Tracking Progress: You can see how things improve over time.

Following Rules: They help meet industry standards.

Training Help: New workers learn faster with clear steps.

For example, a checklist might include steps like measuring product size, checking for defects, and confirming packaging. This ensures nothing is missed.

Note: SOPs don’t just improve quality—they also make work safer and faster. A good SOP can prevent accidents and keep things running smoothly.

Adding checklists and SOPs to your quality checks creates a clear system. This keeps your team focused and your products reliable.

Inspection Software and Digital Tools for Better Results

Today, digital tools are important for quality checks. These tools make inspections faster, more accurate, and easier to track.

How they help:

Save Time: Digital tools speed up work and reduce mistakes.

Quick Updates: You can see problems and fix them right away.

Clear View: Dashboards show how well things are going.

Consistency: Automated tools keep quality the same across all products.

Teamwork: Sharing results is simple, helping everyone work together.

Easy Tracking: Records are stored in one place, making it simple to follow rules.

For example, some software highlights the most serious defects so you can fix them first. Others use diagrams to show inspection steps, so nothing is skipped. Advanced tools even predict problems before they happen.

Reminder: The right software can change how you do quality checks. Choose tools that fit your needs and work well with your current systems.

Using digital tools makes quality checks more accurate and efficient. They help you catch problems early and keep improving.

Measuring and Testing Tools for Accuracy

In quality checks, being exact is very important. You need the right tools to measure and test products correctly. These tools act like a “magnifying glass” for your factory, helping you find even tiny problems. Let’s look at some key tools that improve inspections.

Why Accurate Tools Are Important

Imagine using a ruler with missing numbers to measure fabric. It would be hard, right? That’s what happens without proper tools. Accurate tools make sure products meet exact sizes and standards. They help avoid costly errors, like parts that don’t fit or break easily.

Tip: Spending money on good tools may seem costly, but it saves money by reducing mistakes and fixing fewer problems.

Must-Have Measuring Tools for Inspections

Here are some tools you need for precise measurements:

Calipers: Great for measuring small things like thickness or diameter. Digital calipers give quick and exact results.

Micrometers: Use these for very detailed measurements, especially for tiny parts or thin materials.

Height Gauges: These measure object heights with high accuracy. They ensure all items are the same size.

Tape Measures: A simple tool for bigger measurements. Choose ones with clear marks and strong materials.

Laser Distance Meters: Perfect for quickly measuring long distances. Often used in construction or large factories.

Note: Always check and adjust your tools regularly. Even the best tools can lose accuracy over time.

Tools for Testing Product Strength

Measuring is only part of the job. You also need to test how products perform. Here are some common testing tools:

Tensile Testers: These check how much force a material can take before breaking. Useful in industries like construction.

Hardness Testers: These measure how tough a material is against scratches or dents. Often used for metals and plastics.

Spectrometers: These check the makeup of materials to meet chemical rules.

Multimeters: Great for testing electrical parts. They measure voltage, current, and resistance.

Environmental Chambers: These test products in extreme conditions like heat or cold to check durability.

Reminder: Testing isn’t just about finding problems. It ensures products can handle real-life use.

Picking the Right Tools

Not all tools are the same. Here’s how to choose the best ones:

Know Your Needs: What do you need to measure or test? Pick tools that match your product’s needs.

Check Precision: Look for tools with high accuracy. Small errors can cause big issues.

Think About Durability: Tools should last long and stay accurate with regular use.

Look for Easy Features: Digital displays and simple designs make work faster and easier.

Choose Trusted Brands: Well-known brands often offer better support and warranties.

Taking Care of Your Tools

Good tools are an investment, so take care of them. Here’s how:

Clean Them: Dust can affect accuracy. Wipe tools after use.

Store Safely: Keep tools in a dry, safe place to avoid damage.

Calibrate Often: Regular adjustments keep tools working well.

Train Your Team: Teach everyone how to use and care for tools properly.

Pro Tip: Make a schedule to maintain your tools. This small step keeps them working perfectly.

Technology’s Role in Accuracy

Modern tools have made measuring and testing easier. Digital tools now offer great accuracy and convenience. For example:

3D Scanners: These create detailed models of products to find flaws.

Automated Testing Systems: These handle repeated tasks, saving time and reducing mistakes.

Data Software: Many tools now connect to software to track and study inspection results.

Did You Know? Some advanced tools use AI to predict problems before they happen.

Final Thoughts

Accurate tools are key to quality checks. They help find problems early, ensure consistency, and build customer trust. By choosing and caring for the right tools, you improve your manufacturing process. Invest in the best tools for your needs. Your products—and customers—will benefit.

Benefits of Quality Assurance in Manufacturing

Ensuring Compliance with Industry Standards and Regulations

Quality assurance helps factories follow important rules and standards. Groups like the FDA, ISO, and GMP set strict guidelines. These rules make sure products are safe, reliable, and consistent.

To meet these rules, factories need a strong quality plan. Regular checks and audits help find problems early. CAPA systems fix issues and prevent them from happening again. Keeping clear records shows proof of following the rules during inspections.

Evidence Type | Description |

|---|---|

Regulatory Bodies | |

Risk Management | Finding risks early helps avoid breaking important rules. |

Documentation | Clear records show proof of following the rules. |

Internal Audits | Regular checks keep factories ready for outside inspections. |

CAPA Systems | Fixing and preventing problems keeps quality high. |

Employee Training | Teaching workers ensures they know the latest quality rules. |

By using these steps, factories make better products and avoid problems. Following rules isn’t just about avoiding trouble—it builds trust and shows you care about quality.

Reducing Costs from Defects, Returns, and Rework

Mistakes in products can cost a lot of money. Quality assurance helps catch problems early to save time and resources. Tools like DPMO and DMAIC help measure and fix issues in production.

Bad quality costs include fixing mistakes, throwing away bad items, and losing time. By studying these costs, factories can find ways to improve and save money. Working at higher Sigma Levels means fewer mistakes and lower costs.

For example, if audits show repeated mistakes in a batch, you can change the process to fix it. This stops waste, improves efficiency, and ensures better products.

Enhancing Customer Satisfaction and Brand Trust

Quality assurance is about making products customers love. When products have no defects, customers are happier and more loyal.

Quality checks stop problems so customers get reliable items.

Great products make customers tell others about your brand.

A strong focus on quality builds trust and improves your reputation.

Imagine a customer getting a product that works perfectly. They’ll likely tell friends and stick with your brand. Over time, this trust creates loyal customers and helps your business grow.

By focusing on quality assurance, you don’t just meet rules—you go beyond them. This keeps customers happy and makes your brand stronger.

Supporting Continuous Improvement and Operational Efficiency

Continuous improvement means always finding ways to do better. It’s about making small changes that improve your factory over time. These changes help you work faster and make better products.

Start by watching your production data. Look for problems like defects, delays, or wasted materials. Use tools like Pareto charts or fishbone diagrams to find what’s causing these issues. Once you know the problem, you can fix it.

Get your team involved. They work with the machines and often have smart ideas. Hold meetings to hear their thoughts and plan solutions together. When everyone helps, they’re more likely to support changes.

Automation can also help a lot. Machines and software can do simple tasks faster and with fewer mistakes. For example, automated tools can check product quality while your team focuses on harder jobs. This saves time and keeps your products meeting standards.

Check if your changes are working. Use KPIs like speed, defect rates, or energy use to measure progress. If something isn’t better, adjust your plan and try again.

Make improvement a regular habit. Each month, review your work and find new ways to grow. Even small changes can make a big difference over time.

Tip: Celebrate every success, even small ones. It keeps your team excited and focused on doing better.

By focusing on continuous improvement, you’ll make your factory run smoother and build a reputation for excellence.

Practical Tips for Implementing an Effective Quality Inspection Program

Train and Empower Your Team for Success

Your team is key to good product inspections. When workers know their tasks, they do better. Teach them about quality specifications, tolerance levels, and inspection steps. This helps them find problems early and meet standards.

Use clear inspection rules to guide your team. These rules lower defects by up to 30%, making products better. Encourage teamwork and open talks among workers. Working together keeps them motivated to maintain high standards.

Train your team on tools like Statistical Process Control (SPC). SPC helps spot issues during production, avoiding costly mistakes later. Giving your team the right skills and tools builds a culture of improvement and excellence.

Tip: Update training often to teach new inspection methods and tools.

Establish Clear Quality Metrics and Benchmarks

Clear goals and measures help track progress and keep consistency. They show your team what to aim for and how to check success. Metrics like defect rates and Overall Equipment Effectiveness (OEE) monitor product quality and factory efficiency.

For example, tracking downtime ensures machines work well. Planned maintenance avoids surprise breakdowns. Watching these metrics improves product quality and lowers costs. Customer Satisfaction Scores (CSAT) show how well products meet customer needs.

Outcome | Description |

|---|---|

Better Equipment Reliability | Tracking downtime ensures machines stay reliable. |

Smarter Maintenance Plans | Preventive maintenance avoids surprise breakdowns. |

Lower Costs | Planned maintenance saves money compared to fixing problems later. |

Higher Product Quality | Watching metrics keeps product standards high. |

Happier Customers | CSAT scores show how much customers like your products. |

Note: Check and update benchmarks often to match your goals and industry rules.

Leverage Technology to Streamline Inspections

Technology makes inspections faster and more accurate. Studying past inspection data shows problem patterns. Fixing these early improves compliance and lowers risks.

Predictive maintenance uses past data to predict machine failures. Fixing machines before they break reduces downtime and keeps work smooth. Analytical tools also spot trends, helping plan resources and future strategies.

Digital tools like automated systems and software make inspections easier. They give real-time updates, track results, and show repeated issues. These tools encourage trying new methods and setting smart goals for improvement.

Reminder: Pick technology that works well with your current systems for the best results.

Foster a Culture of Continuous Improvement in Manufacturing

Building a culture of continuous improvement is more than a plan. It’s about helping your team find ways to improve every day. This mindset boosts efficiency, product quality, and team spirit.

Start by asking your team for ideas. They work with machines and materials daily. Their suggestions can lead to big changes. For example, they might find faster ways to assemble parts or notice problems with tools.

Set clear and measurable goals. Instead of saying, “Reduce defects,” aim for “Lower defects by 15% this quarter.” Specific goals help track progress and keep everyone focused.

Encourage open talks. Make it easy for workers to share ideas or point out issues. Hold regular meetings to discuss progress and brainstorm fixes. Reward good ideas to keep your team motivated.

Use technology to help improve. Data tools can show patterns and areas to fix. Automation can reduce repetitive tasks and stop mistakes.

Remember, improvement never ends. Celebrate small wins, but always look for new ways to grow. Small changes over time make a big difference.

Tip: Start with one area to keep things simple. Small steps lead to big results.

How Yansourcing Ensures Quality in Building Materials

Yansourcing’s Comprehensive Quality Inspection Services

Yansourcing makes sure building materials are high quality. Their inspections catch problems early, so you don’t have to worry later. They check every step, from raw materials to finished products. This means the materials you get will meet your needs.

They use three types of inspections: pre-production, in-process, and final checks. For example, they test marble strength or cabinet durability before shipping. Yansourcing also works with outside experts for extra accuracy. This ensures materials follow industry rules and keeps your projects running smoothly.

Tip: Yansourcing gives you more than inspections—they give you confidence in your materials.

Ensuring High Standards for Building Materials

Yansourcing works hard to keep quality high. They team up with trusted suppliers to find materials that meet strict rules. Whether it’s furniture, lights, or tiles, they test everything for strength and performance. This helps avoid delays or fixing mistakes later.

They also check if materials are eco-friendly and safe. For example, they make sure packaging can be recycled and doesn’t have harmful chemicals. This protects the environment and improves your brand’s image.

Reminder: High standards aren’t just about following rules—they’re about delivering great products.

Leveraging Expertise to Address Quality Challenges

Yansourcing has over ten years of experience solving quality problems. They know common issues and how to fix them fast. If a supplier sends bad materials, Yansourcing handles it quickly. They also use advanced tools to track quality and spot trends.

Their help goes beyond inspections. They give advice on better processes and choosing good materials. This way, you always get the best results.

Pro Tip: Working with experts like Yansourcing saves time and ensures top-quality materials.

Success Stories: Yansourcing’s Role in Quality Assurance

Yansourcing doesn’t just talk about quality—it proves it. Here are examples of how they’ve helped businesses succeed with top-notch products.

Lyle Crocodile Bluetooth Speaker: A Customization Success

Imagine needing a product to stand out in two markets. That’s what LRG International wanted for their Lyle Crocodile Bluetooth speaker. They needed different logos, packaging, and designs for the UK and Germany. It wasn’t easy.

Yansourcing made it work. They convinced manufacturers to make smaller batches, even below the usual minimum. Every sample was checked to meet strict quality rules before production. When packaging problems came up, Yansourcing didn’t just fix them—they improved the process to stop future issues.

Result: The speakers launched successfully, with customers loving their quality and unique look.

Building Materials: Strong and Reliable

Yansourcing is great at finding quality building materials. For example, they’ve helped clients get marble tiles that are durable and cabinets that last. They don’t just check materials—they test them for strength, eco-friendliness, and rule compliance.

Yansourcing catches problems early. If a supplier sends bad materials, they act fast to fix it. Their checks ensure every batch meets your needs, saving time and money.

Pro Tip: Yansourcing’s careful inspections mean fewer problems and smoother projects for you.

Why These Stories Matter

These stories show how Yansourcing does more than basic checks. They solve issues, improve systems, and deliver results you can trust. Whether you need custom products or reliable materials, Yansourcing ensures quality at every step.

Reminder: Choosing Yansourcing means choosing expertise, trust, and peace of mind.

Conclusion

Quality checks help you make great products and stay competitive. They’re not just for finding mistakes—they ensure every item meets high standards and makes customers happy. By following a clear inspection process, you save money, work faster, and earn customer trust.

Here’s why they’re important:

Regular checks find problems early, saving time and money.

Happy customers come back and tell others about your brand.

Following rules keeps your business safe from legal trouble.

Over time, inspections lead to better results. For example:

Improvement | Proof |

|---|---|

Less Waste and Fixes | Bad quality can cost 20% of revenue, but checks reduce this. |

Better Productivity | Using SPC boosts work speed by 20-30%. |

Fewer Complaints | Fixing complaints costs $75 each—inspections help avoid them. |

Make quality checks a key part of your work. They’re not just tasks—they’re a way to build trust, follow rules, and deliver top-notch products.

FAQ

1. What’s the difference between quality control and quality inspection?

Quality control checks the whole production process for standards. Quality inspection looks at specific products or batches for problems. Think of inspection as one part of the bigger quality control system.

2. How often should quality inspections happen?

It depends on the product and industry. For important items, inspect at every stage—before, during, and after production. For simpler products, checking samples regularly might be enough.

3. Can machines replace human quality inspections?

Not completely. Machines make inspections faster and more accurate. But humans can spot small issues that machines might miss. Using both together works best.

4. What if a product fails inspection?

Find out what caused the problem, fix it, and check again. If the issue keeps happening, change your process to stop it from repeating.

5. Why is keeping records important in quality inspections?

Records help track problems, show you follow rules, and spot patterns. They also make audits easier and keep everyone working the same way.