How to write product specification sheets and ensure you get the exact product from your supplier?

You often hear about bad experiences with importers and manufacturers. In many cases, the importer is responsible for it all.

Why? The answer is that they did not use product specification sheets.

Writing product specification sheets is almost the first step to making a successful product. After reading this article, you’ll know exactly what to do.

What is a Product Specification Sheet?

A product specification sheet is a document that details what your product is. It should have a broad overview and many sections describing the various components you wish to deliver in your product and clearly labeling all of your product specifications.

This document should be very clear, easy to read, and outline all the information your design team and product team members will need.

Include as much information as possible to ensure that your product team’s specifications are not too vague. A table or chart of the specifications will clarify where to find the details.

Why are Product Specification Sheets Important?

Product specification sheets are used to evaluate a product’s features or components, describe the manufacturing information for an element (details given to the supplier to manufacture the product), or catalog information on the services or products offered.

Many suppliers in the market make products, and many customers buy products. If you don’t have the detailed information needed to get products done or sell them, they will probably move on to another seller/manufacturer.

In this case, product specification sheets become very important.

What is the Main Purpose of a Product Specification Sheet?

1. Help manufacturers understand your requirements

The manufacturer will better understand your requirements if you describe your needs for the product in detail. Importers will mostly fail if they let the manufacturer imagine the requirements of the product.

2. Get a better quote

To make the right offer, the supplier needs to know exactly what you require from the product. Let’s say you are looking for a handbag and you require that the handbag should be high-quality leather.

If there is no product specification sheet, you will get a quote based on cheap quality standards.

3. Sourcing high-quality products

Suppliers take every chance to cut costs as they operate with relatively small margins to expand their business. If you clearly define your product requirements to them, the supplier will not use low-grade packaging and cheap materials.

What to Include in a Product Specification Sheet?

Product specification sheets should be clear and concise. They should provide all the information needed to manufacture the product or understand its features. Here are some details you can include.

1. Introduction

- Product name

- SKU (product code)

- Product Description

- Intended use

- Reference photo (also specify size)

2. Product requirements

- Size and weight

- Specific materials

- Measured tolerances (if any)

- Product color (using Pantone color codes)

- Performance (e.g., durability, high temperature)

- Testing requirements (e.g., list potential defects and expected results)

3. Packaging and labeling requirements

- Packaging specifications

- Labeling specifications

- Testing requirements (e.g., no damage after drop testing)

4. Standards and certification

- Standards

- Certification (e.g., compliance with EU/US standards)

5. Other (optional)

- Special instructions (e.g., private label on the product)

How to Create a Product Specification Sheet?

1. Define the problem

What problem will this product help users solve?

Building a product that does not address a specific business need or consumer demand makes no sense. Ensure that the product instruction indicates the needs and problems that the product will solve.

2. Understand customer input

What do customers exactly want from a new product?

User story gives you an idea of what the new product will accomplish and an assessment of how it will help your customers. Use customer feedback on existing or related products to get a sense of what is happening.

3. Let the whole company in discussion

Stakeholders should have a voice and will be helpful in the development process, which can help you get a lot of helpful input and more support as you complete your work.

4. Pick what product specifications to include

Some specific requirements and specifications are critical for product developers so that the product is safe and usable. Include dimensions, safety standards, expiration details, and product design specifications.

5. Do user testing

Once you have a plan for design and development, make a prototype. Make sure the product is suitable for the customer.

Let them test it, and evaluate it. Check for useful features that are used or lacking and things that are difficult or unpleasant to use.

6. Determine what works or doesn’t work and make changes

Decide what is liked, disliked, complicated, or unnecessary, and based on the results of user testing, fix problems and modify specifications as needed.

What Format Should a Product Specification Sheet be Created in?

Most product specification sheets are created in Excel or Word, but you should send them to your potential suppliers in PDF format.

The reason for this is that the supplier will not modify it, and you can be sure that there are no formatting changes when you email it.

Keep in mind that when you send out a product specification sheet, it will likely be shared and printed among the supplier’s staff via email at any time.

So please include a header or footer with your contact information on each page and page numbers.

How to Use the Product Specification Sheets?

You can use your product specification sheet on several instances, some of which are listed here.

1. Get a Quote

To get a better quote on manufacturing your product, you need to send your product specification sheet to the supplier.

2. Supplier Contracts

When the supplier agrees to work on your product, ask the supplier to sign a contract because they know your project well, which will help you if you need to go through any legal procedures.

3. Quality Control

A quality control inspector will usually check your quality specifications before performing product inspections in China.

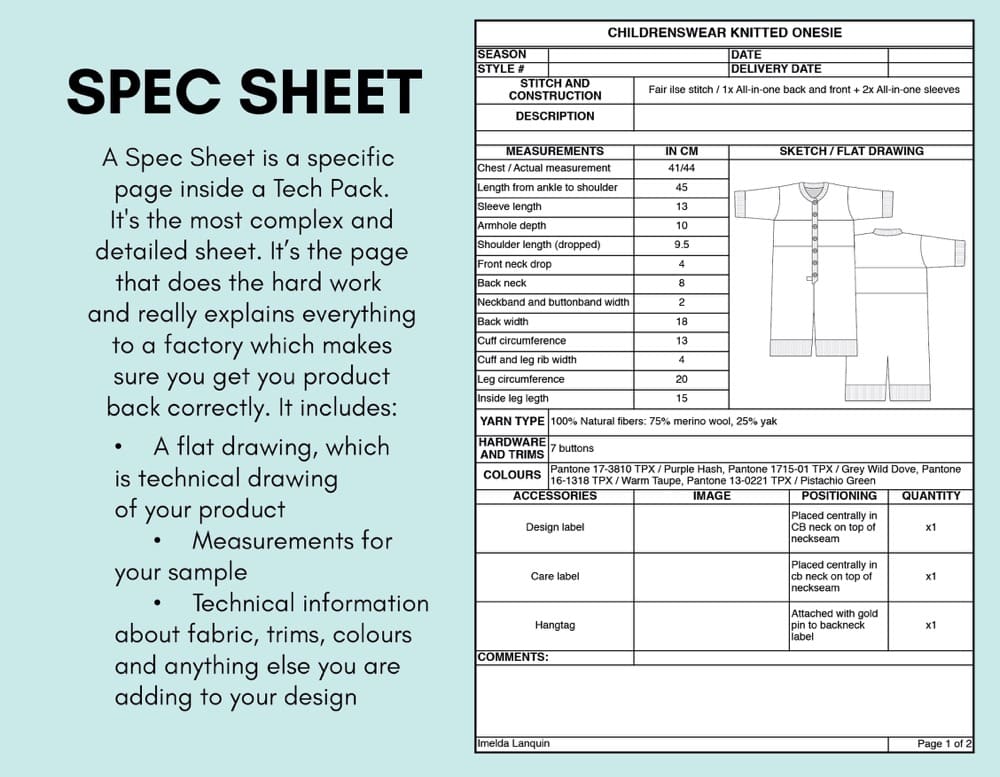

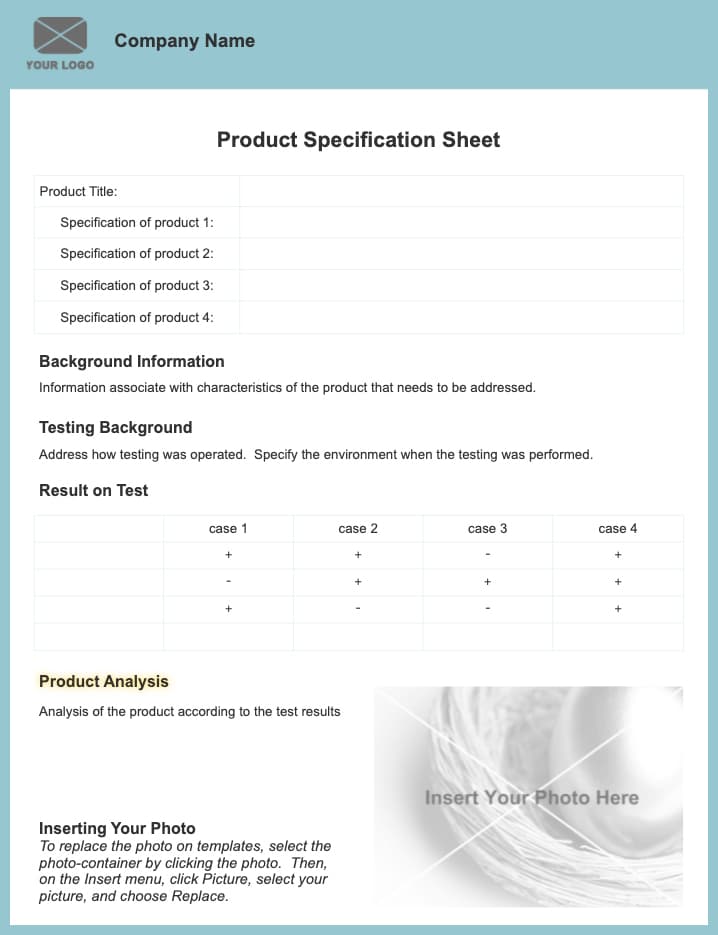

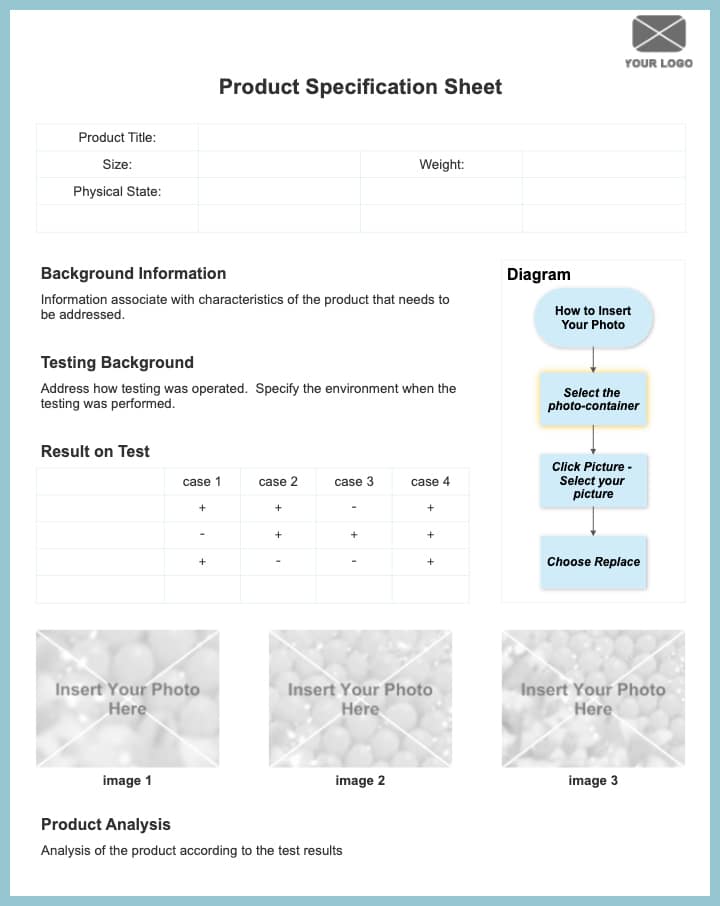

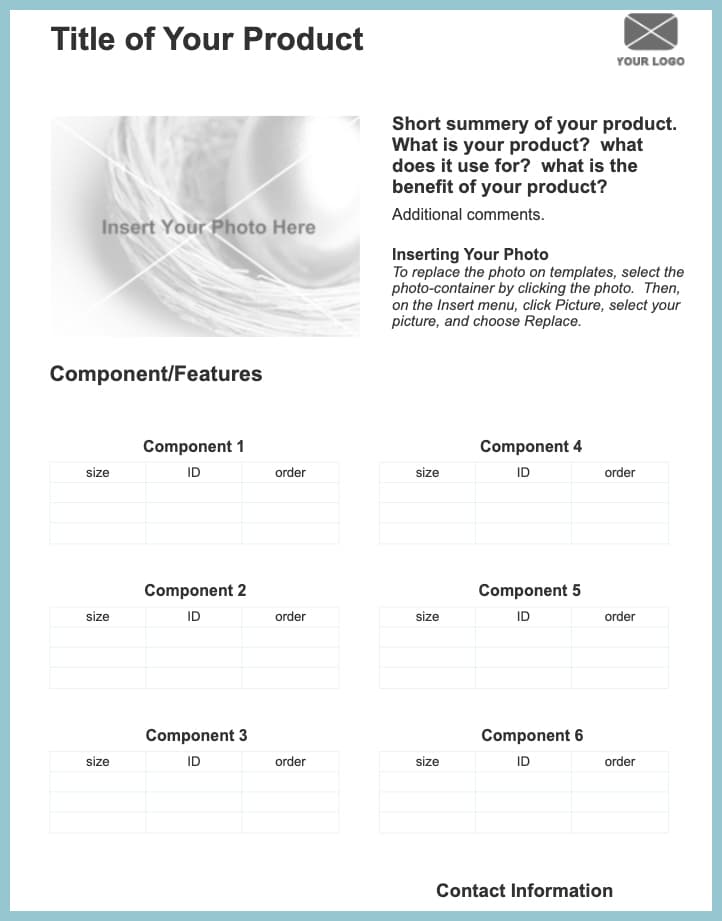

Product Specification Sheets Examples

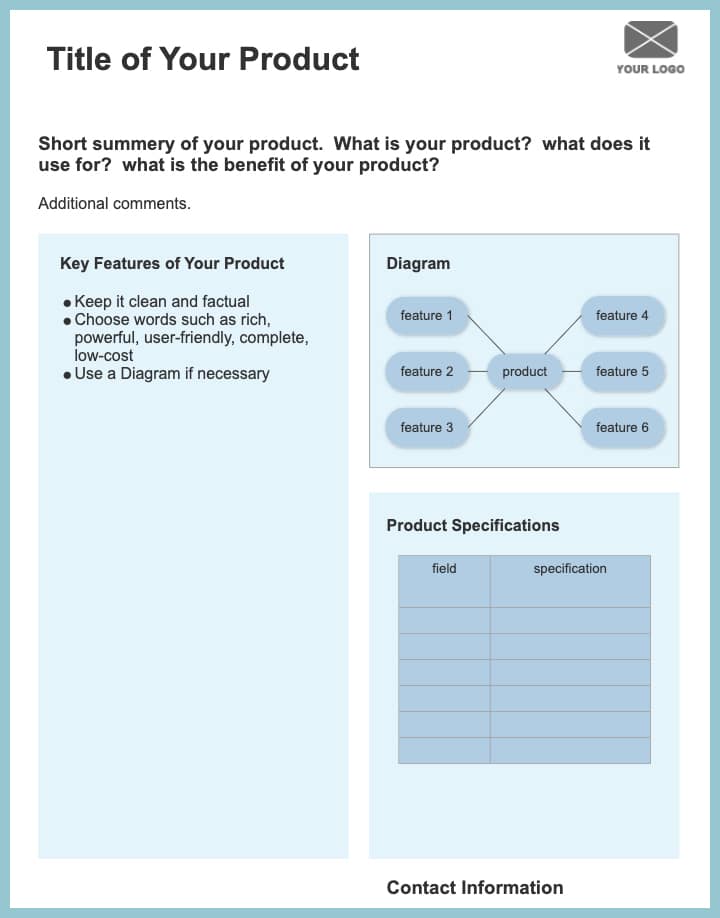

1. This is an example of a product specification sheet template. Customize it with your logo, text, and information.

2. Create an example of a product specification sheet like this one. Add charts and import photos to make it look more professional.

3. Create a product specification sheet example like this template that you can easily edit and customize in minutes.

4. Create a product specification sheet example like this template that you can easily edit and customize in a few minutes.

Product Specification Sheet Conclusion

Product specification sheets are super important. They give suppliers a good idea of what to expect from you. Otherwise, they will cut costs for non-specified requirements.

Are you ready to write one for that product idea that’s been around for a long time? Yansourcing can help you!

We are a reliable China sourcing company because we can source many products for your business. We call it a free plan and create a product specification sheet for your simple sourcing process. Please don’t hesitate to contact us today!