If you’ve ever imported apparel or footwear from China, Japan, or Korea and then watched returns spike because “the size runs small,” you’re not alone.

The core problem isn’t that Asian sizes are mysteriously different—it’s that label-to-label conversions are unreliable. Factories often follow different measurement points, brands interpret ease differently, and tolerance isn’t communicated.

The fix is a measurement-first system: standardize factory SOPs, define tolerance by category, and clarify fit intent on every product page.

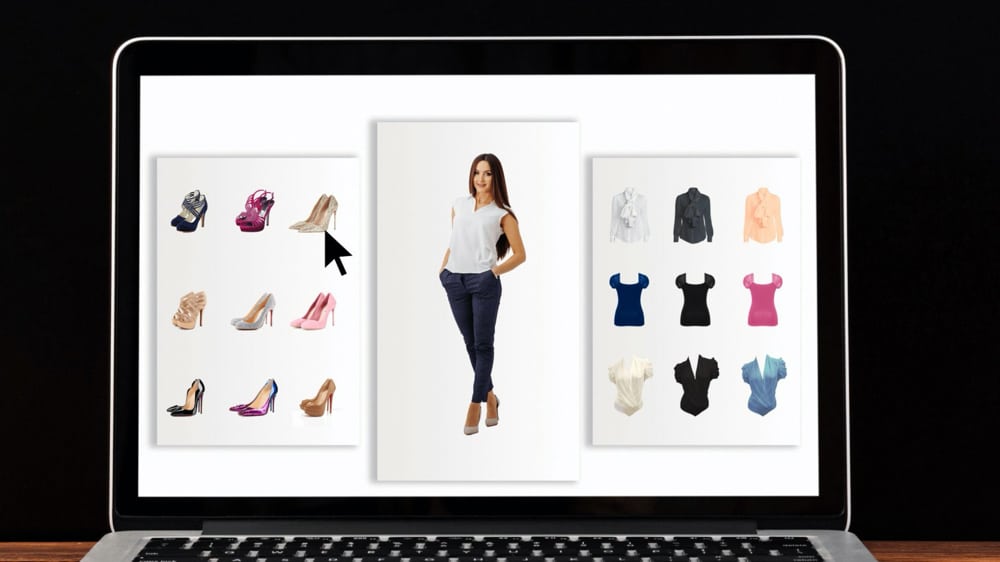

In this guide, you’ll learn how to convert Asian sizes to US sizes without guesswork—grounded in standards, enforced by QC, and implemented in Amazon/Shopify.

We’ll walk through body vs garment measurements, China GB/T sizing logic, JIS and KS context, ISO 8559-1 for definitions, and Mondopoint (ISO 9407) for footwear.

Then we’ll translate this into a practical SOP you can hand to factories and install in your e-commerce stack.

1) Why label-to-label conversion fails

Three forces drive the majority of “size mismatch” returns:

- Vanity sizing: Alpha labels (S/M/L) can drift. A factory’s “S” might match a US “XS”—or even “XXS”—especially in women’s categories and denim.

- Inconsistent measurement points: One factory measures chest at the armpit; another at the bust apex. A different tape position can create >2 cm differences.

- Missing tolerance and fit intent: If you don’t state ± ranges and Slim/Regular/Oversized, customers interpret a garment differently and return it.

The cure: Measure first, convert second. Standardize how and where measurements are taken, declare fit intent (and the underlying ease), and define tolerance by category. Then create size charts that bridge CN/JP/KR labels to US sizing using measurements—not assumptions.

Industry standards support this approach. ISO 8559-1 (2017) describes how to define body measurements for clothing size designation and measurement procedures, providing a common language for measurement points and methods according to the ISO 8559-1:2017 page.

2) Foundations: How sizing systems actually work

Before converting Asian sizes to US sizes, it helps to understand each system’s logic.

2.1 China apparel size logic (GB/T 1335 series)

China’s apparel labels typically show height and chest/bust plus a body-type code—for example, 165/84A. The first number is stature (height, cm), the second is key girth (bust/chest, cm), and the letter indicates body type (A is standard; other letters reflect slimmer or fuller builds).

This format comes from the GB/T 1335 series of standards for size designation. For context on the men’s standard, see the distributor page for GB/T 1335.1-2008 (Men) on chinesestandard.net’s English listing of the standard title and scope GB/T 1335.1-2008 listing.

Apparel labeling rules that reference size/type are covered in China’s consumer textile instructions standard, GB 5296.4-2012; you can find the official listing via the Chinese Standard distributor’s overview page GB 5296.4-2012 overview.

2.2 Japan apparel (JIS) and Korea apparel (KS)

Japan’s JIS apparel sizing designations are grounded in body measurements (height and principal girths), mapping to familiar S/M/L/LL labels.

While many JIS documents are paywalled, official context confirms that clothing sold to the general public uses size indications based on JIS frameworks—the Ministry of Economy, Trade and Industry noted this in a 2023 press communication that references size indications and safety labeling for consumer products METI 2023 press note on JIS size indications.

Korea’s KS apparel sizing similarly uses height and principal girths (e.g., chest for men; bust/waist/hip for women), governed by KS standards managed by KATS/KSA. Exact tables live in the standards; treat KS details as standards-governed and validate against the documents where precision is required.

2.3 US and international context

US-market body measurement tables are published by ASTM for different demographics (e.g., ASTM D5585 for adult female misses; ASTM D6240 for mature men).

These are helpful references when aligning your US charts to measurement-based size mapping. See ASTM’s catalog listing for adult female misses body measurements ASTM D5585 listing and mature men’s body measurements ASTM D6240 listing.

Internationally, ISO 8559-1 (2017) provides definitions of body measurements and procedures, useful when standardizing measurement points and methods across factories ISO 8559-1 (2017) overview.

2.4 Body vs garment and ease

- Body measurements: Stated by standards (ISO 8559-1; GB/T; ASTM). They describe the wearer.

- Garment measurements: The finished item’s dimensions, which include ease—the difference between garment and body measures.

- Fit intent: Define Slim/Regular/Oversized and specify typical ease ranges. For example, a Regular-fit woven shirt might target 6–10 cm bust ease; Oversized could exceed 12–15 cm. Declare your ease targets per category so fit labels are meaningful.

For how to standardize measurement points and diagrams, see a practical tutorial on How to measure clothing.

3) The measurement-first framework (step-by-step)

This is the blueprint we recommend for small to mid-size brands sourcing from CN/JP/KR and selling into US markets.

3.1 Dual labeling: Body vs Garment

- Tech packs: Include both Body and Garment measurements for all control points.

- Customer-facing charts: Show “Body” measurements to guide consumers and note the corresponding “Garment” target ranges with ease.

- Master unit: Use centimeters (cm) as the primary unit and inches as secondary. Keep the conversion constant visible: 1 in = 2.54 cm.

3.2 Define measurement points before sampling

- Provide diagrams for each category and label exact tape positions (e.g., bust apex vs. underarm, natural waist vs. high waist).

- Require factories to photo-confirm measurement points for first samples and PPS (pre-production samples).

3.3 Category tolerance tables

Create a tolerance table and enforce it during sampling and inspections. Typical recommendations:

| Category | Key points | Recommended tolerance |

|---|---|---|

| T-shirts/shirts | chest, shoulder, length | ±1.0 cm |

| Pants | waist, hip, inseam, front rise | ±1.5 cm |

| Outerwear | chest, shoulder, sleeve length | ±2.0 cm |

These tolerance ranges reflect common buyer spec practice and third‑party inspection norms. AQL sampling approaches (e.g., ISO 2859-1) are widely used to enforce such criteria in inspections; see an industry explainer of AQL-by-attributes sampling and lot acceptance according to the HQTS overview of ISO 2859-1 sampling.

3.4 Fit intent markers tied to ease

- Label each style as Slim/Regular/Oversized.

- Define ease ranges per category and fabric (woven vs knit). Add “Fit notes” on PDPs so buyers know what to expect.

3.5 Model data and context

- Always list model height/weight and worn size on PDPs. This helps customers triangulate fit quickly.

3.6 Inspection workflow (batch consistency)

- Sampling: Measure 10 items per batch across key points. Anything outside tolerance is a major defect and triggers rework.

- Multi-factory programs: Lock one measurement SOP and share diagrams. Require photo confirmation for measurement points in sample and PSI.

For a deeper QC overview, you can read a practical guide to Quality control in China and a category-specific Garment inspection checklist.

4) Converting CN/JP/KR apparel labels to US sizes—without guessing

4.1 China CN labels (example: 165/84A)

- 165 = height in cm; 84 = bust/chest in cm; A = body type.

- US mapping: Avoid direct S/M/L equivalence unless you have a validated chart. Instead, anchor on measurements: a women’s blouse targeting a 84 cm bust body measurement may correspond to a US XS/S depending on your brand’s fit intent and ease.

Practical approach:

- Define your US body measurement table (ASTM-informed if applicable).

- Ask factories to provide both Body and Garment specs; crosswalk CN codes to those body measures.

- Build a conversion chart that maps CN labels (height/girth/body-type) to your US alpha/numbered sizes based on body measurement equivalence, not label assumptions.

4.2 Japan (JIS) and Korea (KS) labels

- JIS often uses S/M/L/LL with underlying body dimensions. KS similarly follows body measures.

- US mapping: Extract the underlying body girths/heights from factory specs and map to your US chart. Treat “M” or “L” as a narrative label only; the body measurements are the truth.

Official context that Japanese consumer clothing uses JIS-based indications is described in a 2023 METI press communication METI press communication on JIS indications. Exact measurement tables require access to JIS documents.

4.3 Women’s tops/bottoms/dresses (highest‑risk)

- Vanity sizing is common. Be explicit about Bust/Waist/Hip body measures for each alpha size.

- Declare fit intent; for slim fits, ease is lower, so body-to-garment deltas shrink.

- Present dual units (cm primary, inches secondary) to avoid conversion drift.

4.4 Men’s shirts/outerwear

- Shoulder breadth and sleeve lengths often differ by region. Lock measurement points; ensure factories don’t measure sleeve from neck vs shoulder seam inconsistently.

- Use tolerance tables and note fabric stretch (knits vs wovens) in your ease planning.

For step-by-step chart building, see a focused tutorial on Creating a clothing size chart for your brand.

5) Footwear: use Mondopoint to anchor conversions

US shoe sizes are last-based and vary widely by brand and model. Asian footwear often labels in centimeters (JP) or adopts Mondopoint codes aligned with ISO 9407. To improve consistency, anchor on foot length (mm) and, where possible, foot width.

5.1 What is Mondopoint?

Mondopoint defines shoe size by the wearer’s foot length in millimeters (and optionally width). For background on the standard, see the catalog listing for ISO 9407, which explains the foot-length-based designation system ISO 9407 catalog summary.

5.2 China updated shoe sizing to align with Mondopoint

China’s GB/T 43293-2022 standard updates footwear sizing and marking rules, aligning with Mondopoint and specifying marking requirements (e.g., MP codes). An industry summary from SGS outlines the update and implications for labeling and compliance SGS Safeguards summary on GB/T 43293-2022.

5.3 Japan and Korea footwear

Japan commonly labels shoes in centimeters (e.g., 26.0 cm ≈ 260 mm), compatible with Mondopoint logic. Korea practices foot-length millimeter labeling in many categories. Regardless, last shapes differ; always request last data and width options when sampling.

5.4 Converting to US sizes (approximate)

- Measure the foot length in mm (Mondopoint).

- Use brand-specific last charts to find the closest US size for that last; there is no single universal conversion.

- Provide width notes (e.g., narrow/standard/wide) when possible, as width differences drive comfort and returns.

6) High‑risk categories and nuances

6.1 Women’s apparel

- High return risk due to fit variation and vanity sizing.

- Tighter ease in slim fits makes body-to-garment deltas sensitive to tolerance drift.

- Action: Declare ease by fit type, enforce ±1.0 cm tolerance for key points, show model data.

6.2 Denim

- Fabric stretch and recovery vary; waistband measurements can drift.

- Action: Specify stretch percentage at the waist and hip; add separate tolerance for waistband vs inseam.

6.3 Footwear (men/women)

- Foot morphology and instep height differ by population; last shape matters more than alpha labels.

- Action: Use Mondopoint, capture width, conduct regional last trials before committing to large POs.

6.4 Kids

- Growth-stage deltas make size mapping sensitive. Consider height-first body charts and flexible waist designs.

6.5 Plus-size

- Ensure body-type codes (e.g., CN letter codes) are represented. Ease plans must account for distribution across bust/waist/hip.

6.6 Activewear

- Stretch complicates ease; express intended compression vs relaxed fit and measure garments laid flat with standardized tension.

6.7 Workwear/uniforms

- Functional ease and stability matter. Use looser tolerance on length and reinforce QC given heavy fabric construction.

7) QC and multi‑factory SOP implementation (with example workflow)

A robust QC program makes conversion reliable across factories.

- Pre‑sampling alignment: Share diagrams and a measurement SOP. Factories must photo‑confirm measurement points on first samples.

- Tolerance enforcement: Define category tables; mark out‑of‑tolerance as major defects.

- AQL sampling: Use ISO 2859‑1/ANSI‑ASQ Z1.4 for lot acceptance and inspection counts. See this industry explainer of AQL methodology and tables according to the HQTS guide to AQL sampling.

Example workflow (agent‑coordinated): In multi‑factory programs, a sourcing partner can coordinate a single measurement SOP, collect photo confirmations, and run pre‑shipment inspections focused on size/tolerance.

Yansourcing coordinates factory measurement SOP alignment, photo‑confirmed sampling, and PSI measurement audits for apparel and footwear programs.

Parity note: Brands may implement similar workflows via other sourcing agents or third‑party inspectors; the key is a single SOP and enforcement.

For step‑by‑step QC planning and on‑site checklist design, see Garment inspection checklist and the broader Quality control in China overview.

8) E‑commerce implementation: Amazon & Shopify

8.1 Amazon size charts and PDP content

- Use the size chart self‑serve tool in Seller Central to add measurement‑based charts to your listings. Amazon documents what information to include (body measures, how to measure, units) in its help center; see the guidance on what to include in size charts in the Amazon help hub Amazon help: information to include in your size chart.

- Keep label consistency: The size on the product must match the label on the PDP and the chart.

- Add “Fit notes” (Slim/Regular/Oversized) and model data.

- For footwear, list foot length (mm) and width options where applicable.

For broader listing setup tips, you can reference an implementation primer on How to sell on Amazon.

8.2 Shopify size guides

- Provide a mobile‑friendly size guide with body vs garment measurements, dual units, and how‑to‑measure diagrams. Shopify’s retail blog explains how sizing guides improve conversions and what to include; see the overview on sizing guides and creation steps in the Shopify retail blog Shopify retail blog: sizing guides and how to create them.

- Choose a size chart app that supports multiple charts, US/UK/EU/CN conversions, and responsive UI. Apps like Smart Size Chart and BF Size Chart & Size Guide are common choices; select based on your theme and data structure.

For PDP setup specifics, see an implementation guide on How to sell on Shopify.

9) Case study: standardizing size charts to cut returns

Client context: A mid‑size European brand bought women’s dresses and shirts from factories in Guangzhou and Hangzhou. Online returns hit 28%, mainly “size mismatch” and “fit differences.”

What changed:

- Unified size chart template with diagrams and part descriptions.

- CM as primary unit; inches secondary.

- QC photo‑confirmed measurement points pre‑sampling.

- Tolerance tables by category: T‑shirt ±1 cm; pants waist ±1.5 cm; outerwear ±2 cm.

- Fit intent labels: Slim/Regular/Oversized, declared at sample review.

- Website conversion tool updated for US/UK/EU mapping.

Result in three months: Returns fell to 12.5%; customer size inquiries dropped 40%; factory measurement errors decreased and repeat orders increased. These outcomes reflect one client project’s experience under a standardized SOP; your results depend on product mix, factories, and enforcement rigor.

10) Action toolkit: build your conversion system

Use this checklist to implement measurement‑first conversion from Asia to US:

Measurement SOP

- Dual‑label Body vs Garment in tech packs and PDP charts.

- CM primary; inches secondary (1 in = 2.54 cm).

- Lock measurement points with diagrams; require photo confirmation in sampling.

Tolerance tables

- Preset by category: shirts ±1.0 cm; pants waist ±1.5 cm; outerwear ±2.0 cm.

- Enforce with inspections; classify out‑of‑tolerance as major.

Fit communication

- Declare Slim/Regular/Oversized; tie to ease ranges.

- Add model height/weight/worn size to each PDP.

Footwear

- Capture foot length (mm) and width; use Mondopoint for core mapping.

- Treat US conversions as approximate; validate with last charts.

E‑commerce integration

- Amazon: add measurement‑based size charts and fit notes; keep labels consistent Amazon help on size chart content.

- Shopify: create mobile‑friendly guides with diagrams and dual units Shopify retail blog on sizing guides.

Factory vetting and QC

- Audit suppliers for measurement competence and SOP compliance; see guidance on Clothing manufacturers in China.

- Plan inspections and checklists; see Quality control in China and Garment inspection checklist.

Size chart build

- Construct brand‑specific charts bridging CN/JP/KR to US based on body measures; use this tutorial on Clothing size chart creation.

Final notes and next steps

- Measurement‑first beats label guessing. Use standards (ISO 8559‑1, GB/T 1335, ASTM) to define body measures, lock garment ease and fit intent, and enforce tolerance via inspections.

- Footwear: Prioritize Mondopoint and width; align CN labels with GB/T 43293‑2022 and validate conversions via last charts.

- Multi‑factory programs need one SOP, photo‑confirmed measurement points, and AQL‑driven inspections.

Ready to implement? Download your “Asian Size Conversion & Measurement SOP Toolkit,” submit your SKU list for a free size‑logic check, or book a 1‑on‑1 sizing/QC consultation with a dedicated advisor.

For broader sourcing context, explore a primer on How to source clothing from China, and if returns are hurting margins, see strategies to Reduce returns in e‑commerce.