If you’re moving from prototyping to stable CNC production in China, this guide is your playbook. You’ll learn exactly how to spec, vet, quote, sample, qualify, control, ship, and improve—without getting trapped by unclear drawings, misaligned tolerances, or late deliveries.

Throughout, we’ll share pragmatic checklists, quality frameworks, cost drivers, and negotiation tactics, plus where Yansourcing’s on‑the‑ground team can de‑risk each step.

Who this is for: SMB procurement managers and manufacturing/mechanical engineers who need reliable Chinese CNC suppliers and predictable total landed cost.

Primary outcomes you’ll achieve:

- Build a bulletproof RFQ package and normalize supplier quotes apples‑to‑apples

- Match part complexity and tolerances to the right supplier tier and machine class

- Run FAI/PPAP correctly, set up AQL/SPC/MSA, and prevent quality drift

- Pick the right Incoterms, packaging, and logistics path for flawless delivery

- Negotiate value (capability, throughput, quality) without sacrificing cost

Quick credibility note: This guide references authoritative standards and data, including the 2025 context for capabilities and logistics.

See inline citations to sources like the SAE AS9102C First Article Inspection standard (SAE, 2023), AIAG PPAP/APQP/MSA/SPC manuals (AIAG, current), ISO 2859‑1 AQL sampling (ISO, 1999), Incoterms 2020 (ICC), and 2024–2025 logistics context from the Flexport Ocean Timeliness Indicator (2025 snapshot).

Executive summary (read this if you’re in a hurry)

The 80/20 of success in China CNC sourcing:

- Specify what truly matters. Rationalize tolerances and finishes; over‑tight specs drive cost and scrap without adding functional value. Industry guidance shows moving from ±0.05 mm to ±0.01 mm can hike costs 20–50% or more due to slower feeds, precision setups, and inspection intensity, a pattern echoed across 2024–2025 manufacturing resources such as Longsheng’s CNC price drivers and Xometry’s 3‑ vs 5‑axis overview (2024).

- Match supplier tier to part risk. Not every shop is set up for ±0.005 mm features or complex 5‑axis work; align machine class, metrology, and process control to your CTQs.

- Lock the process early. Use DFM, golden samples, and FAI/PPAP to stabilize before scaling. For FAI, the canonical reference is SAE’s AS9102C; for automotive launches, use AIAG PPAP/APQP.

- Inspect smartly. Plan AQL for attributes and SPC for CTQs. ISO 2859‑1 (General Inspection Level II) is the common baseline for acceptance sampling, per the ISO 2859‑1 standard page and AQL planners such as TetraInspection’s calculator (aligned to ISO 2859‑1).

- Don’t forget packaging and logistics. Use Incoterms 2020 correctly (per the ICC), validate packaging (ISTA 3A for common parcel/LTL scenarios), and compute landed cost.

Cost reality check (2025 indicative):

- Machine-hour: common 3–4 axis roughly $20–$60/hr; high‑end 5‑axis/mill‑turn roughly $50–$100/hr in quality shops. These conservative bands reflect 2024–2025 conditions triangulated from industry sources such as HPL Machining’s China rate context and platform guidance on complexity premiums like Xometry’s 3‑ vs 5‑axis. Always normalize quotes before deciding.

Quick-start roadmap: CNC sourcing in 10 steps

- Define the spec pack: 2D drawings w/ GD&T, 3D STEP, tolerance/finish matrix, material standard and certs requirement (e.g., EN 10204 3.1), volumes, packaging, and inspection plan stub.

- Screen suppliers: certifications, machine list, metrology (CMM brand/model), past PPM/OTD, process controls (SPC/MSA), capacity, and finishing partners.

- RFQ and quote normalization: standardize quote inputs; split setup vs piece price; include finishing and inspection time; compute TCO.

- DFM loop: clarify tight features, add reliefs/fillets, rationalize tolerances/finishes, confirm tool access; resubmit for updated quotes.

- Sampling: build fixtures, run pilot; align on golden sample, color/finish chips, and measurement method/gages.

- FAI/PPAP: approve first‑article per AS9102 or PPAP level as appropriate; freeze process window, control plan, and CTQ list.

- In‑process and final QC: SPC on CTQs, AQL plan for attributes, MSA/Gage R&R on critical measurements, calibration logs.

- Packaging & logistics: ISTA‑aligned packaging, corrosion protection, labeling; choose Incoterms; verify HS codes and documents.

- Pre‑shipment inspection and release: conduct PSI per AQL; verify CMM reports and certs; approve ship date.

- After‑sales CAPA: if defects or delays occur, run root cause, corrective/preventive actions, and supplier development.

Where Yansourcing helps most: supplier vetting, DFM facilitation, FAI/PPAP orchestration, AQL/SPC setup, and end‑to‑end logistics.

Capabilities in China: machines, materials, finishes, and tolerance realities

What’s widely available in 2025:

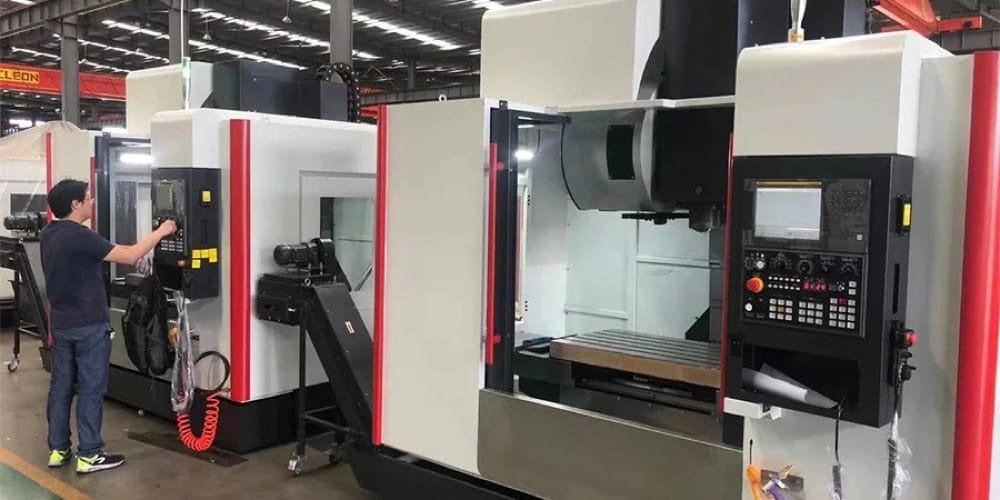

- Machines: 3/4/5‑axis milling, CNC turning, mill‑turn centers, wire/sinker EDM, surface/cylindrical grinding; plus heat treatment, anodizing, plating, passivation, bead blasting.

- Tolerances: For production CNC, ±0.01–0.05 mm is typical depending on feature/material; ±0.005–0.01 mm is achievable with capable machines and process control; grinding/EDM can reach sub‑10 μm on justified criticals. These ranges align with 2024–2025 industry summaries such as Rally Precision’s capability overview.

- Surface finish (Ra): CNC machining often ~0.8–3.2 μm; grinding/EDM can achieve ~0.1–0.4 μm for fine surfaces, consistent with manufacturing and metrology guidance like Komacut’s surface roughness guide (2024).

- Metrology: CMMs are common. For context, Mitutoyo’s CRYSTA-Apex lists sub‑micron repeatability and published MPE specs, and Zeiss high‑end CMMs publish μm‑level MPE; see data sheets via CMM‑Compass Mitutoyo CRYSTA‑Apex and Zeiss XENOS comparisons.

Standards and defaults to reference:

- Use ISO 2768 for general tolerances (classes f/m/c) and tighten only where function demands; overview in 3ERP’s ISO 2768 guide (2024).

- Define GD&T on critical features; specify surface roughness targets only as needed.

- Call out inspection method and gage on CTQs to prevent measurement disputes.

Cost modeling and negotiation: from quotes to TCO

Think in three layers: fixed costs, variable costs, and risk/quality costs.

- Fixed: programming, setup, fixturing; spread over quantity.

- Variable: cycle time (feeds/speeds, toolpaths), tool wear, finishing operations, inspection time.

- Risk/quality: scrap, rework, line‑down penalties, expedited freight.

2025 indicative ranges and drivers:

- Hourly machine rates: 3–4 axis roughly $20–$60/hr; 5‑axis/mill‑turn roughly $50–$100/hr in quality shops. Complexity premiums are well‑documented in platform guidance like Xometry’s 3‑ vs 5‑axis article (2024) and commercial context pieces such as HPL Machining’s China rate overview.

- Materials: Aluminum 6061 is the baseline; 7075, stainless (304/316), and tool steels raise time/wear and price bands; see summarized cost drivers in Yijin Solution’s machining cost factors (2024).

- Tolerances/finishes: Tightening from ±0.05 to ±0.01 mm and adding hard‑coat anodizing or plating can materially increase cycle and inspection minutes; this pattern is echoed in 2024–2025 manufacturing explainers like Longsheng’s pricing factors.

Quote normalization checklist (use this before choosing):

- Break out setup vs piece price and inspection/finishing line items.

- Confirm material spec and cert level (e.g., EN 10204 3.1) is included.

- Require estimated cycle time and operation routing (milling, turning, EDM, grinding, finishing, inspection).

- Validate inspection scope (FAI, CMM time, SPC sampling) and packaging.

- Compute total landed cost under your chosen Incoterm and lane.

Negotiation that preserves capability:

- Trade tolerances/finishes that don’t affect function for price/time relief.

- Consolidate features to reduce setups; allow standard radii or add reliefs to improve tool access.

- Discuss production control: if the supplier runs SPC on CTQs and owns a capable CMM, accept a slightly higher piece price to avoid quality drift. Value beats the cheapest quote over the product life.

Ask Yansourcing to benchmark your current quotes and surface hidden assumptions: Get a quote normalization review.

Supplier selection in China: tiers, audits, and red flags

Supplier tiering (rule of thumb):

- Tier A: 5‑axis/mill‑turn cells, automotive/aerospace pedigrees (IATF/AS9100), robust metrology (CMM, vision, form testers), SPC/MSA culture, in‑house finishing partners. Use for tight tolerances (≤±0.01 mm), complex geometries, or regulated sectors.

- Tier B: Solid 3/4‑axis and turning with selective 5‑axis access; ISO 9001, decent CMM; can hold ±0.02–0.05 mm on production with guidance. Good for mixed assemblies and most SMB programs.

- Tier C: Job shops focused on simpler parts, limited metrology, ad‑hoc controls; best for prototypes, jigs/fixtures, and low‑risk brackets.

Audit essentials:

- Capability matrix: machine list with envelopes; routine tolerances by feature; materials; finishing network; CAM/ERP/MES usage; CMM brand/model; calibration status.

- Quality system: control plans, SPC on CTQs, MSA samples, corrective action history, FAI records.

- Performance: OTD, PPM, rework rates, customer references.

- IP/security: NNN agreements, data access control, visitor logs.

Standards alignment for approvals draws on AIAG PPAP/APQP frameworks (current manuals) and FAI using AS9102C (SAE, 2023).

Red flags:

- No calibrated CMM or vague measurement plans; outsourcing without disclosure; weak change control; unstable staff/shift patterns; reluctance to share routing or CTQs.

Need a vetted shortlist matched to your drawings? Request a supplier verification + audit pack via Yansourcing.

DFM and sampling: avoid rework and surprises

Practical DFM tips we use again and again:

- Tolerance rationalization: default most non‑critical dims to ISO 2768‑m/f, with GD&T only on true CTQs; see expectations in 3ERP’s ISO 2768 overview (2024).

- Tool access and radii: allow standard fillets; avoid sharp internal corners; add machining reliefs where pockets meet walls.

- Wall thickness: avoid ultra‑thin unsupported walls; add ribs or adjust geometry.

- Datum strategy: define stable datums for fixturing and measurement; call out measurement method on CTQs.

Sampling and golden sample alignment:

- Produce pilot pieces under near‑production conditions.

- Lock color/finish chips, edges, deburr quality, and packaging presentation.

- Align on CMM program and gage list to prevent method bias.

Yansourcing’s engineering team can host a DFM workshop on your CAD and return a marked‑up drawing set with proposed tolerance/feature changes.

Quality control system: FAI/PPAP, AQL, SPC, and MSA

When to use which framework:

- FAI (First Article Inspection): Validate that the process can produce a part that meets drawing and spec before mass production; formalized by AS9102C (SAE, 2023). Even outside aerospace, the forms (ballooned drawing, characteristic accountability, material/process certs) are excellent discipline.

- PPAP/APQP (Automotive): For higher‑risk parts or tier‑1 programs, apply AIAG PPAP/APQP: control plan, PFMEA, process flow, MSA results, capability data (Cp/Cpk) on CTQs.

Attribute acceptance sampling (AQL):

- ISO 2859‑1 (GII) is the common default; you choose AQLs for Critical/Major/Minor based on risk. As a worked example referenced by industry AQL planners: for lot size 501–1,200 units (code letter K), sample size is 125; AQL 1.0 has Ac3/Re4; AQL 2.5 Ac7/Re8; AQL 4.0 Ac10/Re11—see the ISO 2859‑1 standard page (ISO, 1999) and calculators like TetraInspection’s ISO‑aligned AQL tool.

Variable control (SPC) and capability:

- Put control charts on CTQs (e.g., bore diameter, flatness). Track Cp/Cpk during pilot and early production; maintain during mass production per standard SPC practice as summarized in quality engineering primers (e.g., AIAG SPC overview).

MSA/Gage R&R:

- Validate measurement systems to avoid chasing measurement noise. The AIAG MSA manual remains the de‑facto reference; for CMMs, align with ISO 10360 declarations from the manufacturer.

Pre‑shipment inspection (PSI):

- Run PSI to the agreed AQL plan; confirm CMM reports, certs (material, heat treat, plating/anodizing), and packaging conformity before you release shipment.

Yansourcing can implement your control plan, supervise FAI/PPAP submissions, and run AQL‑based PSIs with bilingual QC engineers.

Packaging, logistics, and trade compliance

Packaging that protects precision:

- Use form‑fitted foam or custom dunnage; isolate cosmetic surfaces; add VCI paper/film and desiccants for corrosion‑prone metals. Validate with ISTA drop/vibration protocols—ISTA 3A is a common general simulation method for parcel/LTL packages; see ISTA 3A overview (ISTA, official PDF).

- Label parts, include orientation/handling symbols, and add humidity indicators where needed.

Logistics choices and Incoterms:

- Align responsibilities and risk using Incoterms 2020; refer to the official ICC Incoterms rules. Choose EXW/FOB for buyer‑managed freight, CIF/CFR for port delivery, DDP for door‑to‑door simplicity.

- Transit time ballparks in 2025: Refer to snapshots such as the Flexport Ocean Timeliness Indicator (2025) for lane‑level variability. Air freight door‑to‑door often ranges 3–7 days depending on consolidation and customs.

Trade compliance basics:

- Use correct HS/HTS codes based on material/function; consult official databases like the US ITC HTS search (USITC) or EU TARIC. Include commercial invoice, packing list, COO, and test/cert docs as required.

Yansourcing can package to ISTA standards, plan your Incoterms, and manage customs clearance and delivery.

Risk and IP protection in China

Use China‑specific legal and operational controls:

- Sign NNN (Non‑Disclosure, Non‑Use, Non‑Circumvention) agreements drafted in Chinese, under Chinese law, and enforceable in Chinese courts. Legal experts repeatedly explain why Western NDAs fall short in China and why NNNs are superior; see the Harris Sliwoski guide to China NNN agreements (2024–2025).

- Register trademarks and relevant patents/designs in China (first‑to‑file). Consider split BOM/split manufacturing and stage‑gated sharing of sensitive drawings.

- Control access to CAD/CAM, watermark shared drawings, define visitor rules, and conduct periodic audits.

Yansourcing enforces supplier NNNs, controls document sharing, and can set up split manufacturing when appropriate.

Transformation case study (anonymized): from 12% rejects and late deliveries to stable supply

Context: A North American SMB ordered 8–12k pieces/year of a 3‑operation aluminum turned‑milled part with two tight CTQs: a ±0.01 mm bore and parallelism ≤0.02 mm after anodizing.

Initial supplier missed targets: 12% final rejects, rework bottlenecks, and two late shipments in three months.

Root causes we found:

- Drawing ambiguity on datum scheme; CMM and shop gage measured from different datums.

- Over‑constrained tolerance on a cosmetic boss that didn’t affect function, adding cycle time and scrap.

- No MSA; gage repeatability issues on the bore ID causing false rejects.

- Inadequate racking in anodizing, causing distortion and parallelism drift.

- Packaging scuffs causing cosmetic rejections at incoming inspection.

Actions and fixes:

- Drawing clarification: updated datum structure; removed tight tolerance from cosmetic boss; added GD&T on true functional features.

- MSA/Gage R&R: validated bore ID measurement; switched to calibrated three‑point bore gage; aligned CMM program.

- Process control: SPC on bore ID with Cp/Cpk targets ≥1.33; pilot run demonstrated stability.

- Anodizing racking: revised racking positions and introduced stress‑relief; frozen parameters.

- Packaging upgrade: custom foam dunnage with surface protection and VCI.

- AQL plan: GII with Critical 0.65, Major 1.5–2.5, Minor 4.0; introduced PSI with hold‑to‑ship gate.

Results after 2 months:

- First‑pass yield improved from 84% to 98.6%; final rejects <0.8%.

- OTD back to 98% with buffer WIP and a weekly cadence report.

- Piece price unchanged; savings achieved through cycle‑time reduction and scrap elimination offset quality system costs.

This pattern mirrors disciplined use of FAI, SPC, and MSA as promoted in standards like AS9102C for FAI (SAE, 2023) and AIAG SPC/MSA manuals.

Toolkits you can use immediately (in‑article versions)

Below are concise, copy‑and‑use toolkits:

1. CNC RFQ Spec Pack (minimum contents)

- 2D drawing (PDF) with GD&T and revision, plus 3D (STEP/IGES)

- Tolerance & finish matrix (Ra targets, anodize/plating specs, bead‑blast notes)

- Material callouts (e.g., Al 6061‑T6) and certs (EN 10204 3.1)

- Annual volume, EOQ, and first PO quantity; desired lead times

- Critical‑to‑Quality (CTQ) list and inspection plan stub (methods/gages)

- Packaging requirements (foam, VCI, individual bag, labeling)

- Compliance notes (RoHS/REACH as applicable)

- Incoterm and destination; preferred shipping mode

2. DFM Checklist (most common wins)

- Default non‑critical dims to ISO 2768‑m or ‑f; GD&T only on functionals

- Add fillets to internal corners; allow standard tool radii

- Verify minimum wall thickness and add ribs if needed

- Ensure tool access/clearance; avoid deep narrow slots

- Consolidate setups when possible; datum strategy for fixturing

- Specify measurement method for CTQs; align CMM program early

3. AQL Planning Starter (ISO 2859‑1, GII)

- Choose levels: Critical 0–1.0, Major 1.5–2.5, Minor 4.0 as a starting point

- Example: Lot 501–1,200 → Code K → sample size 125; AQL 1.0 Ac3/Re4; 2.5 Ac7/Re8; 4.0 Ac10/Re11 (align with your risk profile); see ISO 2859‑1 page (ISO) and AQL calculator aligned to ISO (TetraInspection)

4. FAI/PPAP Starter Kit (what to require)

- Ballooned drawing with characteristic list linked to inspection results

- Material and special process certs (anodize/plating/heat treat)

- Process flow, control plan with CTQs, and capability data (Cp/Cpk)

- MSA summary (gage R&R) on critical measurements

- For aerospace use AS9102C forms; for automotive see AIAG PPAP/APQP

5. Quote Normalization Worksheet (headings)

- Supplier, machine class, metrology assets

- Setup/programming, cycle time by operation, tool wear

- Finishing line items, inspection time (FAI/CMM/SPC)

- Packaging, Incoterm, freight estimate

- Risks/assumptions; warranty/after‑sales terms

To receive editable Excel/Word versions, request the “CNC RFQ + DFM + QC Pack” from Yansourcing.

How Yansourcing helps (and where to engage)

Supplier verification and capability matching

Factory audits, machine/metrology checks, certification validation, past PPM/OTD review. CTA: Request a vetted supplier shortlist → Yansourcing

Engineering DFM and sampling

Drawing clarification, tolerance rationalization, pilot sampling, golden sample control. CTA: Book a 30‑minute DFM consult → Yansourcing

Quality control and approvals

FAI/PPAP project management, control plans, SPC on CTQs, MSA/Gage R&R setup, pre‑shipment inspection using ISO 2859‑1 AQL. CTA: Download our QC toolkit (request editable pack) → Yansourcing

Packaging, logistics, and landed cost

ISTA‑aligned packaging, Incoterms planning, customs clearance, and global delivery. CTA: Get a total landed cost estimate → Yansourcing

After‑sales CAPA and supplier recovery

Root‑cause analysis, corrective/preventive actions, layered process audits, and supply stabilization. CTA: Start a supplier recovery plan → Yansourcing

Frequently asked questions (fast answers)

What tolerances are realistic for SMB production in China?

For most features, ±0.01–0.05 mm depending on geometry and material, with ±0.005–0.01 mm feasible under capable processes and inspection. See capability summaries like Rally Precision’s 2024 guide.

How long does it take?

Prototypes 5–12 working days; small batch 2–4 weeks; larger batches 4–8+ weeks depending on finishing and capacity—consistent with 2024–2025 summaries across China machining providers such as Rally Precision.

Which Incoterm should I use?

If you have a forwarder, FOB is a common balance. If you want simplicity, consider DDP. Use the official ICC Incoterms 2020 rules as your reference.

How do I protect IP?

Use China‑specific NNNs, register IP in China, and control document access—see the Harris Sliwoski NNN primer (2024–2025).

Your next step

- Primary CTA: Book a free CNC sourcing consultation (drawings review, vetted supplier shortlist, QC/logistics plan) → Yansourcing

- Secondary CTA: Ask for the “CNC RFQ + DFM + QC Pack” (editable toolkits) → Yansourcing

- Micro‑CTA: Have live quotes? Ask us to benchmark and normalize them before you commit → Yansourcing