Knowing how to manufacture a product is very important. It helps turn your product idea into reality. Did you know 55% of factories work on being faster? Also, 53% focus on creating new ideas. These facts show why learning the steps to make a product is key.

This is where Yansourcing helps. They make the hard parts of manufacturing easier. They guide you in finding materials and checking quality. With their help, you can focus on your idea while they do the tough work.

Start this process with a clear plan and smart goals. A good plan saves time, cuts costs, and makes work faster by over 30%. Are you ready to begin?

Key Takeaways

Begin with a simple plan and clear goals to save time and money in making products.

Study the market carefully to learn what customers want and check your product idea before starting.

Use Yansourcing to find good factories, control costs, and keep quality high during production.

Make a sample product to test your idea, which can save money and make customers trust your brand more.

Collect customer opinions after launch to make your product better and keep strong connections with users.

Conceptualization and Research

Finding a problem to solve

Great products fix everyday problems. Think about what people need help with. Is there something missing in the market your idea can provide? Many successful products started by solving simple issues, like better ways to store things or faster tools.

When you find a problem, you’re starting to build a product people will like. Market research is important here. It shows what customers want and helps find new chances to succeed.

Tip: Focus on what your audience really needs. This makes your product useful and unique.

Testing your idea with market research

After you have an idea, check if people want it. Study similar products to see how they’re doing. Look at sales numbers, reviews, and market trends. This step shows if your idea can work.

Ways to test your idea:

Check how often people search for related words online.

Ask people directly through interviews or small group talks.

Use social media to see if people are interested.

Good testing includes clear goals, like:

Keep over 50% of users coming back in six months.

Grow active users by 20% every month.

Get customer ratings above 4.5 out of 5.

These goals show if your idea fits what the market wants.

Planning costs and checking feasibility with Yansourcing’s help

Making a product needs smart planning. You should check early if your idea is possible and affordable. Yansourcing makes this easier by helping with research and cost checks. They also help with prototypes to keep quality high and costs low.

What Yansourcing can do for you:

Find trustworthy factories for production.

Break down costs for making, testing, and shipping.

Make sure your product meets safety rules.

Note: Creativity is key in manufacturing. Use customer feedback and market trends to make a product that works well and sells.

With Yansourcing, you can move forward knowing your product is ready to be made and fits your plan.

Design and Prototyping

Making a design or plan for your product

Every good product begins with a clear plan. This step is where you create a detailed design or plan. It shows how your product will look and work. Think of it as a guide to making your product. Start by focusing on these important steps:

Decide what your product should do.

Choose materials that fit your idea.

Follow any legal rules, like safety standards.

Research is very important here. For example:

Talking to people helps you learn what they need.

Surveys give numbers to support your choices.

A smart design saves time and money. It also makes sure your product works for customers.

Making a prototype to test your idea

After your design is ready, build a prototype. A prototype is a sample of your product. It lets you test how your idea works in real life.

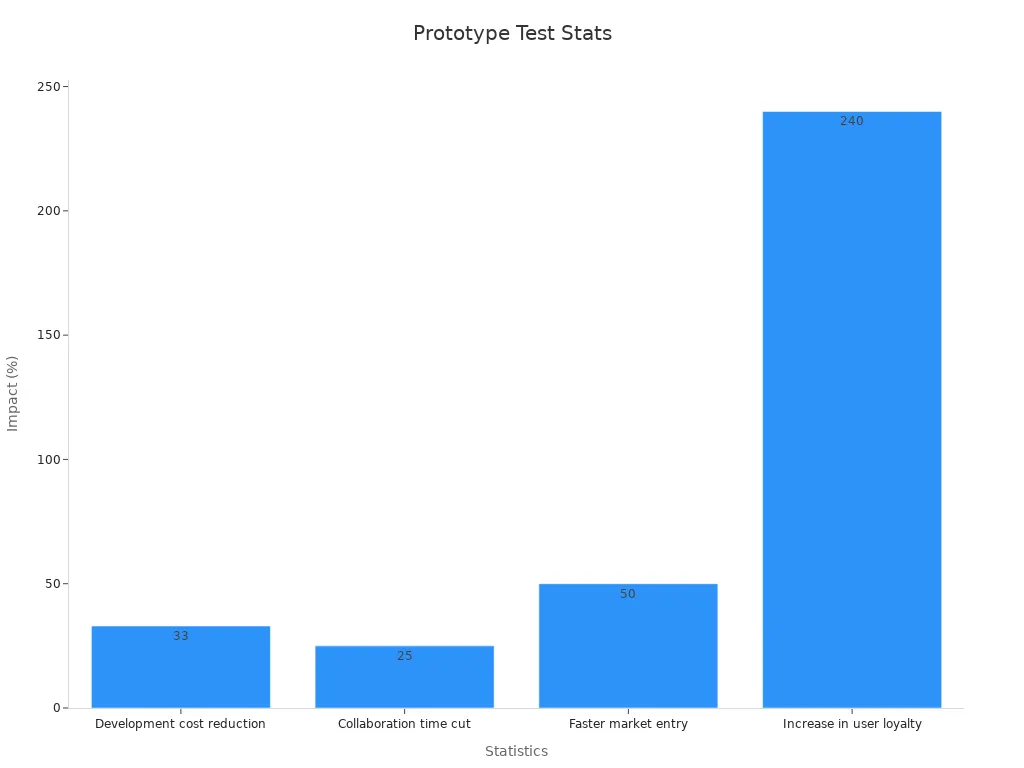

Why is a prototype so helpful? It lowers costs by 33%, gets your product to market faster by 50%, and makes users 240% more loyal. Here’s a quick view of the benefits:

Statistic | Impact |

|---|---|

Lower development costs | 33% |

Shorter teamwork time | 25% |

Faster market launch | 50% |

Higher user loyalty | 240% |

Testing your prototype makes sure it works well. It also helps you find problems early.

Improving the prototype with feedback

After testing, you might find things to fix. This is where improving comes in. Improving means changing your prototype based on feedback. It’s a process of testing, learning, and fixing.

Two good ways to improve your prototype are:

Usability Testing: Watch people use your product to find problems.

A/B Testing: Test two versions to see which one works better.

Testing Method | Description |

|---|---|

Usability Testing | Lets real users try the product to find issues. |

A/B Testing | Compares two versions to see which one users like more. |

Products that use customer feedback during testing succeed 50% more often. Improving your product makes it better and more likely to succeed.

Tip: Keep improving until your product meets your goals and makes your customers happy.

Making a Product with Yansourcing

Starting to make a product can feel confusing. You might think about using local or overseas factories. You may also wonder how to compare prices or build good partnerships. This section will explain these steps and show how Yansourcing makes it easier. By the end, you’ll feel ready to start making your product.

Picking between local and overseas factories

The first big choice is where to make your product. Should you pick local or overseas factories? Each has good and bad points. The best choice depends on your product, money, and goals. Here’s a simple comparison:

Factor | Local Factories | Overseas Factories |

|---|---|---|

Economic Stability | More stable for long-term plans | Less stable, which may cause risks |

Financial Incentives | Offers tax breaks and research credits | Often lacks such benefits |

Technological Advancements | Better access to new technology | May not have the latest tools |

Workforce Quality | Skilled workers available | Workers may need more training |

Infrastructure | Strong systems for smooth production | Systems may not be as developed |

Local factories give better stability, skilled workers, and new tools. But they often cost more. Overseas factories save money but may have problems like delays or communication issues. Yansourcing helps you decide which option fits your needs.

Tip: Think about your product’s type and buyers. For example, tech products may need local expertise, while simple items could be cheaper overseas.

Asking for prices and comparing them

After choosing where to make your product, ask for prices. This helps you know the costs and compare options. Follow these steps to do it well:

Write clear details about your product. Include size, materials, and features.

Contact several factories. This gives you different price options.

Ask for cost details. Check production, shipping, and extra fees.

Yansourcing makes this step simple. They connect you with trusted factories and give clear cost estimates. They also find hidden costs, like taxes or quality checks, so there are no surprises.

Note: Don’t just pick the cheapest option. Look for value. A slightly higher price might mean better quality or faster delivery.

Making deals and building trust

Good deals help create strong factory partnerships. They make sure both sides agree on what to expect. Use these steps to make fair deals:

Know your goals. Be clear about what you need.

Learn about the factory. Understand their strengths and limits.

Build trust. A good relationship makes deals easier.

Stay open. Be ready to adjust terms for both sides.

Yansourcing is great at this. They help you get fair deals and keep good relationships with factories. They also handle language and culture differences, making things smooth.

Callout: A good partnership is key to making your product successfully. Take time to build it right.

By following these steps and using Yansourcing’s help, you can easily find a factory, compare prices, and build partnerships. This ensures your product-making journey starts strong.

Product Manufacturing and Quality Control

When your product design and prototype are ready, it’s time to start manufacturing. This is the step where your idea becomes a real product. Scaling production, keeping quality high, and managing deadlines can feel tough. Let’s break it into simple steps to make it easier.

Scaling production to meet demand

Scaling production means making more products to match customer needs. It’s important when your product becomes popular. But how can you scale without spending too much or lowering quality?

Here’s how to scale production:

Know market demand: Make sure you produce what customers need.

Set clear goals: Plan targets like making 20% more in six months.

Create a roadmap: Plan each step to avoid problems.

Work as a team: Make sure all departments work together smoothly.

Track your progress with these metrics:

Metric | What It Tracks |

|---|---|

Asset Use | Check if machines are running well without wasting time. |

Throughput | Count how many products you make per hour to meet demand. |

Maintenance Time | Track machine downtime to fix issues quickly. |

Watch for defects to keep products consistent and improve them. |

Scaling isn’t just about making more products. It’s about doing it smartly while saving money. Yansourcing helps you find good factories and keeps scaling on track.

Tip: Start small and grow slowly. This helps you avoid risks and keep quality high.

Keeping quality high with Yansourcing’s help

Quality control makes sure your products are good and reliable. Without it, customers might stop trusting your brand. Scaling production can bring problems like defects or uneven quality. That’s why a strong quality system is so important.

Here’s how to keep quality high:

Check often: Look at products during every step to catch problems early.

Use smart tools: Automated checks find defects fast and prevent mistakes.

Test small batches: Try small runs before full production to spot issues.

Yansourcing is great at quality control. They check factories, test samples, and watch production closely. Their help saves time and ensures your product meets safety rules and customer needs.

Callout: A good Quality Management System (QMS) helps follow rules and makes production more efficient.

Managing deadlines and solving production problems

Finishing on time is very important in manufacturing. Delays can hurt sales and upset customers. Managing deadlines while fixing problems takes careful planning.

Here are common problems and solutions:

Problem | Solution |

|---|---|

Too much or too little inventory. | Use just-in-time (JIT) methods to lower storage costs. |

Old inventory costing money. | Use forecasting tools to adjust stock levels. |

Adding new technology. | Start small with tools that can grow later. |

Workers needing more skills. | Offer training programs to improve their abilities. |

Relying on one supplier. | Use multiple suppliers to avoid risks. |

To stay on track, focus on these key indicators:

KPI Type | What It Tracks |

|---|---|

Quality KPIs | Watch defect rates and customer happiness to keep standards high. |

Financial KPIs | Track costs and profits to stay successful. |

Efficiency KPIs | Measure production speed and find ways to improve. |

Yansourcing helps solve these problems by working with suppliers, tracking deadlines, and improving team communication. Their skills in logistics and production keep your project moving forward.

Note: Managing timelines isn’t just about being fast. It’s about balancing speed, quality, and cost for the best results.

By focusing on scaling, quality control, and deadlines, you can handle manufacturing challenges easily. With Yansourcing’s help, you’ll have the tools to succeed and bring your product to market.

Launch Your Product and Gather Feedback

Creating a plan to market your product

A good marketing plan helps your product succeed. It connects you with the right people and builds excitement. Start by figuring out who your customers are. What do they want? What problems can your product solve for them? Once you know this, you can create messages that speak to them.

Follow these three steps to guide your plan:

Step | Purpose | |

|---|---|---|

Before Launch | Sign-ups, social media likes, early campaign interest | Check if people are excited and adjust your plan. |

During Launch | Activation rate, website clicks, feature usage | See how people respond and use your product when it goes live. |

After Launch | Product usage, customer activity, satisfaction | Measure long-term success and plan for future updates. |

Look at numbers like how many people buy, leave, or return. Use social media, emails, and influencers to spread the word. A strong plan makes sure your product gets noticed.

Tip: Try your ideas on a small group first. This helps you fix problems before spending too much.

Getting feedback from customers after launch

Once your product is out, customer feedback is very important. It tells you what works and what needs fixing. Ask customers to share their thoughts through surveys, reviews, or messages.

Watch these key numbers to learn about customer behavior:

Metric | Description |

|---|---|

Shows how many people use your product after signing up. | |

Customer Retention Rate | Tracks how many people keep using your product over time. |

Customer Satisfaction Score | Measures how happy users are and what can be improved. |

Listening to customers builds trust and keeps them coming back. It also helps you find new ideas for updates.

Callout: Happy customers often tell others about your product. Their good reviews can bring in new buyers.

Using feedback to improve and grow

Feedback isn’t just for listening—it’s for making changes. Use it to make your product better. For example, Amazon used customer feedback to grow into a market leader. Other companies, like PlanHub, improved their features and launched faster by listening to users.

Here’s how to use feedback:

Find common problems or requests.

Focus on changes that help the most people.

Test updates with a small group before sharing them widely.

Improving your product keeps it useful and competitive. It also shows customers you care about their opinions, which builds loyalty.

Note: Growing your product isn’t just about making more. It’s about improving quality and meeting customer needs as they grow.

Conclusion

Making a product has many important steps. You start by finding a need, then move to making more products and asking for feedback. Here’s a simple overview:

What It Does | |

|---|---|

Data Collection | Gather useful information to make smart choices. |

Statistical Analysis | Study the data to improve how things are done. |

Control Charts | Use charts to check if things are working well. |

Process Capability Analysis | Make sure your process meets quality rules. |

Continuous Improvement | Keep making your product and process better over time. |

Yansourcing makes this process easier. They find good factories, manage costs, and check quality. Their help lets you focus on your idea while they handle the hard parts.

Start by learning about your product idea and making a plan. Being flexible is very important. Improving your product helps you stay ahead, waste less, and work better.

Tip: Begin small, listen to feedback, and keep improving. Success comes from staying open to change and working hard.

FAQ

1. How do I begin making my product?

Start with a clear plan for your product. Include details like design, materials, and features. Look for manufacturers who make similar items. Share your idea clearly with them. Yansourcing helps you find trusted factories and guides you step by step.

2. What should I show to a manufacturer?

Give clear details about your product. Include its size, materials, and special features. Add drawings or a sample if you can. This helps the factory understand your idea better. Yansourcing makes sure your presentation looks professional and clear.

3. How do I make sure my product is good quality?

Check quality during production. Test samples often and look for problems. Yansourcing does strict checks to ensure your product is safe and meets customer needs.

4. Should I pick local or overseas factories?

Local factories have skilled workers and are more stable. Overseas factories cost less but may have risks. Choose based on your budget and product type. Yansourcing helps you decide what works best for you.

5. What if there are delays or problems?

Be ready to adjust and plan ahead. Use tools to track progress and fix issues. Yansourcing helps solve problems fast by working with suppliers and improving communication.