When developing a new product, choosing the right manufacturing approach is crucial. Two popular methods—OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer)—are revolutionizing how businesses bring products to life and enter competitive markets. These approaches enable companies to transform ideas into tangible products, whether by designing everything from scratch or leveraging pre-existing designs.

Why does this matter? The global market for oem odm clothing is projected to expand from $199.26 billion in 2024 to $436.36 billion by 2033, growing at a steady annual rate of 9.1%. This highlights the critical role these methods play in helping businesses thrive in challenging markets.

Understanding how oem odm processes work allows you to align them with your business objectives, paving the way for growth and success. Let’s dive into these options to discover the best path for your business.

Key Takeaways

OEM lets you control the product design fully. It’s great for making unique items that match your brand.

ODM helps you enter the market faster with ready-made designs. Pick ODM if you want to launch quickly and save on design costs.

Think about your industry and product needs when deciding. Some industries like custom designs, while others prefer ready-made products.

Both options have good and bad sides. Compare control, cost, and speed to choose what works best for your business.

Yansourcing can guide you through OEM and ODM choices. They find trustworthy manufacturers and check quality during production.

Understanding OEM and ODM Manufacturing Models

What is the OEM (Original Equipment Manufacturer) Model?

The OEM model gives you control and flexibility. You create the product design and share the details with the manufacturer. They then make the product for you. This is great if you have a unique idea and want full control over design and branding.

OEM is common in industries like cars and electronics. For example, electric car companies use this model to make custom batteries or parts. The numbers show its growth. By 2037, the OEM market could reach $71.4 billion, growing 4.7% each year. In 2023, electric car sales rose by 35%, increasing battery demand to over 750 GWh.

This model lets you make something special. But it takes more work for design, development, and managing intellectual property. If you’re ready to put in the effort, OEM can help your product stand out.

Metric | Value |

|---|---|

Market size by 2037 | $71.4 billion |

Annual growth rate (CAGR) | 4.7% |

EV sales increase (2023) | 3.5 million (35% rise) |

EV battery demand (2023) | Over 750 GWh (40% rise) |

What is the ODM (Original Design Manufacturer) Model?

The ODM model makes things easier. The manufacturer has a ready-made product that you can customize with your brand. This is perfect if you want to launch quickly without spending much on design.

ODM is popular in industries like fashion, electronics, and home goods. The ODM market is growing fast. In 2023, it was worth $128 billion, with a yearly growth rate of 5.4%. By 2032, it might grow to $203 billion.

This model saves time and money. You don’t need to create a product from scratch. Instead, you can focus on branding and selling. It’s a smart choice if you’re entering a busy market and need to act fast.

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | 128 | 5.4 |

2032 | 203 | N/A |

Both OEM and ODM have their own benefits. Picking the right one depends on your goals, budget, and timeline. Next, we’ll explore their pros and cons to help you choose.

Advantages and Disadvantages of OEM and ODM Models

When picking between OEM and ODM, knowing their pros and cons helps. Let’s break it down simply.

Advantages of the OEM Model

OEM is great for businesses wanting full control over products. Here’s why it’s special:

Better product quality: OEM makes high-quality items based on your needs.

Unique designs: You can create products that match your brand’s style.

Own your ideas: You keep full rights to your product’s design and details.

Save money: Making in bulk with OEM lowers production costs.

Focus on strengths: Let OEM handle production while you focus on selling.

Benefit | What It Means |

|---|---|

Save Money | Bulk production with OEM reduces costs. |

Focus on Strengths | Outsourcing lets you work on marketing and sales. |

Expert Help | OEM provides knowledge for industries needing precision. |

High Quality | OEM ensures reliable products with fewer recalls. |

Disadvantages of the OEM Model

OEM has challenges too. Think about these before deciding:

Big upfront costs: Custom designs need a lot of money to start.

Takes longer: Customizing products can delay launches.

Depend on others: Your business relies on the OEM being reliable.

Hard to connect systems: Extra work may be needed to fit their products with yours.

Stuck with one vendor: Switching manufacturers can be expensive and tricky.

Advantages of the ODM Manufacturing Model

ODM makes production easier and faster. It’s great for quick launches. Here’s why:

Lower risk: ODM uses tested designs, so fewer mistakes happen.

Save resources: You spend less on research and tools, focusing on sales.

All-in-one service: ODM handles testing, design, and production for you.

Faster launches: Pre-made designs mean quicker product releases.

Cheaper per item: Making more items lowers the cost of each one.

Advantage | What It Means |

|---|---|

Save Resources | ODM helps brands save on research and development costs. |

Focus on Selling | Brands can focus on sales while ODM handles production. |

All-in-One Service | ODM takes care of testing and product creation, making things simpler. |

Both models have good and bad sides. The best choice depends on your goals, money, and timeline. Next, we’ll compare OEM and ODM to help you decide.

Disadvantages of the ODM Manufacturing Model

The ODM model is fast and easy, but it has downsides. Knowing these issues can help you decide if it works for you.

One big problem is less control over the product. The manufacturer owns the design, so you can’t change much. This makes it hard to create a unique product. If standing out is important, this might not be the best choice.

Another challenge is the tough competition in the ODM market. Many companies use this model, so prices and product options are very competitive. This can make it harder to earn good profits, especially in crowded industries.

Here’s a simple look at some key problems with the ODM model:

Problem | What It Means |

|---|---|

Tough Competition | Many businesses use ODM, making it hard to stand out or earn profits. |

Less Product Control | You can’t change designs much, limiting your product’s uniqueness. |

Using pre-made designs can also hurt your brand’s identity. Your product might look like others, confusing customers or making your brand less special.

Lastly, while ODM saves time and money at first, it may cost more later. Limited changes and relying on the manufacturer can slow your growth as your business expands.

By thinking about these downsides, you can match your strategy to your goals. If saving time and money matters more than customization, ODM could still be a smart option.

Key Differences Between OEM and ODM Models

Choosing between OEM and ODM depends on your business needs. Let’s look at three main areas: control over design, customization and branding, and intellectual property.

Control Over Product Design and Development

With OEM, you control the product design completely. You create the plan, and the manufacturer builds it. This is great if you have a unique idea and want every detail perfect. For example, designing a new gadget lets you pick materials and features.

ODM gives less control. Manufacturers offer ready-made designs you can slightly adjust. This saves time but limits uniqueness. If speed matters more than originality, ODM might work better.

Tip: Pick OEM for full design control. Choose ODM for speed and ease.

Level of Customization and Branding

OEM allows full customization. You can design every part to match your brand. From materials to features, everything can reflect your style. This also gives you full control over branding, making your product stand out.

ODM offers limited changes. You can tweak colors or add a logo to pre-made designs. It’s faster and cheaper but less unique. If building a strong brand is key, OEM is the better option.

Model | Branding Potential | |

|---|---|---|

OEM | High (client designs) | Full control over branding |

ODM | Limited (pre-existing designs) | Less control over branding |

Note: Use OEM to create a unique product. ODM is faster but limits branding options.

Intellectual Property Considerations

OEM helps protect your ideas. Since you design the product, you own it. This means you can improve it and keep competitors away. But OEM costs more upfront and takes longer to develop.

ODM has risks with intellectual property. The manufacturer owns the design, so you have less control. Competitors might sell similar products, making it harder to stand out. While faster, ODM may limit your brand’s uniqueness.

Approach | Advantages | Challenges |

|---|---|---|

OEM | – Full control over design and features | – Higher upfront costs for research |

– Unique, branded products | – Longer time-to-market | |

– Easy to improve and modify | – Needs more resources for development | |

ODM | – Pre-designed products for quick use | – Less control over design |

– Faster market entry | – Similar products may exist | |

– Limited uniqueness |

Tip: Choose OEM to protect your ideas. Use ODM for faster production.

By knowing these differences, you can pick the right model. Whether you need control, speed, or customization, there’s an option for you.

Cost Implications for Businesses

Choosing between OEM and ODM affects your business costs. Each model has different financial needs that can impact profits.

OEM needs more money upfront. You pay for design, development, and tools. This cost can lead to better profits later. Owning the product’s IP lets you make unique items. Mass production with OEM also lowers the cost per item over time.

ODM is cheaper to start. The manufacturer gives pre-made designs, saving development costs. But scaling production can raise per-item costs. ODM makers often share profits, which lowers your earnings.

Here’s a simple cost comparison:

Model | Initial Investment | Production Costs | Profit Margins |

|---|---|---|---|

OEM | Lower per item in bulk | Higher from unique products and IP | |

ODM | Lower upfront costs | Higher per item when scaling | Lower due to shared profits |

Tip: Use OEM for unique products if you have the budget. Choose ODM for a cheaper way to enter the market quickly.

Time to Market and Scalability

Launching a product fast is important for earning money. Both OEM and ODM offer different speeds and growth options.

OEM takes longer. You design the product, test it, and set up production. This makes a special product but delays the launch. Once ready, OEM lets you scale production easily based on demand.

ODM is quicker. Pre-made designs skip the long development process. You can focus on branding and selling. ODM also makes scaling simple. You can adjust order sizes without big production changes.

Here’s how they compare:

Aspect | OEM Partnership | ODM Partnership |

|---|---|---|

Cost Savings | Similar savings from outsourcing | |

Time to Market | Slower, up to 50% longer | Faster with pre-made designs |

Scalability | Flexible scaling by demand | Easy order adjustments |

Note: Pick ODM for faster launches. Choose OEM for long-term growth and flexibility.

By comparing these factors, you can pick the best model. Whether you want lower costs, faster launches, or easy scaling, knowing these differences helps you decide.

Picking the Best Model for Your Business with Yansourcing

Choosing a manufacturing model can feel confusing. Should you pick OEM or ODM? Yansourcing makes this choice simpler. They help match your goals, budget, and market needs. In this section, learn how to decide based on key factors. Yansourcing guides you to balance cost, quality, and speed for success.

Things to Think About: Industry, Product, and Market Goals

Every business is different, so your needs matter. First, check your industry. Are you in electronics, fashion, or home goods? Some industries prefer OEM for custom designs. Others use ODM for ready-made products.

Next, look at your product. Does it need special features or advanced tech? If yes, OEM might be better. For simple items like bags or toys, ODM saves time and money.

Finally, think about your market goals. Do you want to launch fast or build a strong brand? ODM helps you start quickly. OEM lets you create unique products for long-term success.

Tip: Write down your industry, product type, and goals. Use this list to decide wisely.

Matching the Model to Your Business Goals

Your goals should guide your choice. Want a unique product? OEM gives full control over design and branding. You can make something special that fits your vision.

If you need to enter the market fast, ODM works well. Pre-made products let you focus on branding and sales. You skip the long development process.

Yansourcing helps match your goals to the right model. Their team listens to your needs and suggests the best option. Whether it’s a custom smartwatch or branded bag, Yansourcing ensures your strategy works.

Balancing Cost, Quality, and Speed with Yansourcing

Balancing cost, quality, and speed is hard but important. OEM costs more upfront but makes unique, high-quality products. ODM is cheaper and faster but limits customization.

Yansourcing makes this easier. They connect you with trusted manufacturers offering good prices and quality. Their logistics expertise ensures fast delivery without lowering standards.

For example, Vietnam Mobile World wanted a smartwatch called BEFIT S1. Yansourcing helped them customize an existing model. They delivered a great product on time and within budget.

Note: Yansourcing’s full support helps you balance these factors for success.

Choosing the right model doesn’t have to be hard. With Yansourcing’s help, you can make smart choices that fit your goals and grow your business.

Case Study: How Yansourcing Helped Create the BEFIT S1 Smartwatch

Ever think about how an idea becomes a real product? This story shows how Yansourcing helped Vietnam Mobile World make the BEFIT S1 smartwatch. You’ll learn how they solved problems, found solutions, and achieved success. If you want a partner to bring your product idea to life, this example will inspire you.

The Challenge

Vietnam Mobile World wanted to rival the XiaoMi COLOR 2 smartwatch. They needed a product with similar quality and features but a unique design. Their goal was to create a smartwatch for the Vietnamese market while staying on budget and meeting tight deadlines.

Here’s what they had to overcome:

Tricky design needs: The watch had to look stylish and feel strong.

Feature improvements: Functions like heart rate tracking needed upgrades.

Localization: The interface had to work for Vietnamese users.

Time pressure: The product had to launch quickly to meet demand.

These challenges called for a partner who could handle everything from start to finish.

The Solution

Yansourcing came in with a clear plan. They didn’t just find manufacturers—they managed the whole process.

Here’s what they did:

Factory choice: Yansourcing visited factories to pick the best one.

Design updates: They improved the watch’s frame and strap for a better look.

Feature upgrades: They added sports modes and improved heart rate tracking.

Localization: They translated the interface for Vietnamese users.

Smart project management: Using existing models saved time and money.

Note: Yansourcing’s careful planning made sure every step met Vietnam Mobile World’s needs.

The Results

The BEFIT S1 smartwatch was finished on time and exceeded expectations. It included:

A sleek, durable design that stood out.

Better features like accurate heart rate tracking and more sports modes.

A localized interface that fit Vietnamese users perfectly.

Vietnam Mobile World launched the smartwatch successfully, gaining an edge in the tech market.

Feature | Improvement Made by Yansourcing |

|---|---|

Design | Stylish zinc alloy frame and strap |

Functionality | Improved heart rate tracking |

Localization | Vietnamese language support |

Why It Matters

This story shows how Yansourcing turns problems into solutions. Whether you need better designs, localization, or fast delivery, they have the skills to help.

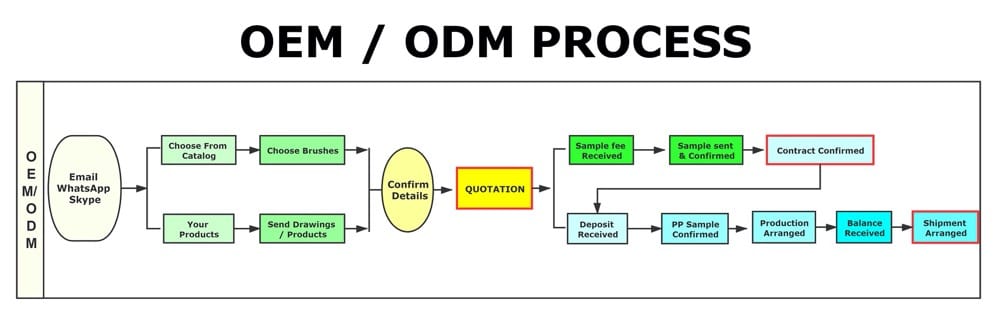

How Yansourcing Helps with OEM and ODM Manufacturing for Consumer Products

Bringing your product idea to life needs the right partner. Yansourcing helps businesses handle the challenges of OEM and ODM manufacturing. Whether you want custom designs or ready-made products, Yansourcing ensures smooth production and top-quality results.

Easy Product Sourcing Services

Yansourcing makes finding manufacturers simple. They connect you with trusted factories for OEM and ODM production. Their team checks suppliers and handles price talks. You don’t need to search for factories or manage communication. Yansourcing saves you time and ensures high standards.

Tip: Let Yansourcing handle sourcing while you focus on selling your products.

Quality Checks and Shipping Solutions

Quality is important in making products. Yansourcing checks every step of production to catch problems early. They also handle shipping and storage, making sure your products arrive safely and on time. Their process avoids delays and keeps things running smoothly.

Note: Yansourcing ensures your products are high-quality and delivered without trouble.

Customizing Products and Packaging

Customizing makes your brand unique. Yansourcing helps adjust designs for OEM or brand pre-made ODM items. They also help with packaging design, creating a professional look that attracts buyers. Their designers work closely with you to meet your needs.

End-to-End Support for Product Development

Creating a product can feel like a big task. There are many steps, like finding a manufacturer and checking quality. Yansourcing makes this process easier. They guide you through every step, whether you choose OEM or ODM models.

You won’t have to handle tricky production steps alone. Yansourcing finds skilled manufacturers who know what you need. They help with designing, testing, and making your product. This keeps costs low while ensuring great quality.

Here’s why their help is important:

Benefit | What It Means |

|---|---|

Expert Knowledge | Yansourcing works with OEMs who are skilled in making top-quality products. |

Faster Production | Their trusted manufacturers speed up the process, so you launch sooner. |

Using OEMs lowers research costs while giving you custom solutions. | |

Quality Control | Yansourcing ensures strong, reliable products through trusted partners. |

This support saves time and money while reducing stress. You can focus on growing your business as Yansourcing handles the hard work.

Picture launching a product that’s market-ready without the usual stress. Yansourcing’s team ensures every detail matches your vision. From packaging to scaling production, they take care of it all.

Conclusion

Picking between OEM and ODM depends on what your business needs. OEM lets you control the design fully, perfect for unique ideas. ODM helps you launch faster by using ready-made designs. Both have good and bad sides, so match the model to your goals.

In 2023, OEM held a big part of the global market. Both models are growing fast, especially in industries like electronics and fashion. These areas show where new chances are appearing.

Yansourcing makes choosing easier. They link you with reliable manufacturers to ensure quality and speed. Want to move forward? Explore your choices, check your budget, and let Yansourcing help you succeed.

FAQ

1. What’s the difference between OEM and ODM manufacturing?

OEM lets you create your own product design. ODM uses ready-made designs that you can adjust. OEM gives more control over design and branding. ODM is quicker and costs less to start. Pick based on your needs and goals.

2. How do I decide between OEM and ODM for my business?

Think about your product, money, and time. OEM is better for custom designs. ODM works well for fast launches. Yansourcing can help you choose the best option for your business.

3. Can Yansourcing help with both OEM and ODM manufacturing?

Yes, Yansourcing handles both models. They find good manufacturers, check quality, and manage shipping. Whether you need custom or ready-made products, Yansourcing supports every step.

4. How long does it take to launch a product with OEM or ODM?

OEM takes months because of design and testing. ODM is faster since designs are already made. Yansourcing helps speed up the process for both options.

5. Is it expensive to use OEM compared to ODM?

OEM costs more at first but can make more money later. ODM is cheaper to start and good for quick entry. Yansourcing helps keep costs low while ensuring great quality.