Choosing the right way to make products is important in 2025. How you create items affects quality, costs, and your brand’s success. For example, using smart manufacturing plans can cut defects by 35%. It can also lower inventory by 25%. This doesn’t just save money—it makes work smoother and keeps you ahead.

So, how do you pick between OEM vs ODM? OEM (Original Equipment Manufacturer) lets you control design and quality fully, allowing for customization that aligns with your brand vision. On the other hand, ODM (Original Design Manufacturer) offers ready-made, cheaper solutions that can expedite your time to market. Both have good points, but your choice between OEM vs ODM depends on your business needs. This guide will explain these options and help you decide wisely.

Key Takeaways

OEM lets you control product design fully. It’s great for businesses wanting special, high-quality items that match their brand.

ODM gives you pre-made designs. This means faster production and lower costs, which is perfect for new businesses or those with small budgets.

Think about your goals: pick OEM for custom products and strong branding. Choose ODM for quick production and saving money.

Watch out for hidden costs in both options. Talking clearly with manufacturers can help you avoid surprise expenses.

Plan for growth. OEM helps you grow slowly with unique items. ODM lets you grow fast to meet market needs.

Understanding OEM and ODM Manufacturing Models

What is OEM (Original Equipment Manufacturer)?

OEM means a company makes products based on your designs. You give them the plans, and they create the product. This lets you control how it looks, works, and feels. For example, if you’re making a smartwatch, you choose the materials and features.

OEM is common in industries like electronics, cars, and medical tools. It helps businesses focus on selling and marketing while the factory makes the items. But it costs more because you need to design everything. This works best for companies with clear ideas and enough money for custom products.

What is ODM (Original Design Manufacturer)?

ODM is a simpler option. The factory has ready-made designs you can slightly change. It’s like picking a base model and adding your brand to it. This saves time and money since the design is already done.

ODM is great for businesses that want to start fast without spending much. For example, if you want to sell headphones, the factory might offer a basic model. You can add your logo and packaging to make it yours. This is perfect for startups or small companies with tight budgets.

Key Characteristics of OEM and ODM

Knowing how OEM and ODM differ helps you pick the right one. Here are their main features:

OEM Manufacturing:

You control the design and quality.

Needs detailed plans and more money.

Best for unique, branded items.

ODM Manufacturing:

Uses pre-made designs with small changes.

Cheaper and faster to launch.

Good for saving money and time.

Tip: New tech like machine learning is improving both OEM and ODM. It helps find defects, manage stock, and save energy, making production cheaper and better.

Advantages and Disadvantages of OEM Manufacturing

Benefits of OEM for Customization and Brand Identity

OEM lets you control how your products are made. You design every part, from materials to appearance. This ensures your products match your brand’s style.

A big benefit of OEM is making unique items. You can create products that stand out. For example, if you’re making a smartwatch, you can pick features like heart rate tracking or a cool metal frame. This helps your brand grow and keeps customers loyal.

Another advantage is better quality. Since you design the product, you can make sure it meets your standards. This lowers the chance of mistakes and makes customers happy. These benefits make OEM great for businesses wanting special, high-quality products.

Tip: Choose OEM if you want products that show your brand’s values. It helps build trust with your customers.

Challenges of OEM: Costs and Time Investment

OEM has downsides too. One problem is the high cost. Making a new product needs a lot of money. You’ll pay for testing, molds, and other tools. This can be hard for small businesses or startups.

Another issue is time. OEM takes many steps, like designing and producing. This can take months and delay your product launch. If your market is competitive, this could hurt your chances.

You also need clear communication with the factory. Misunderstandings can cause delays or mistakes, costing you more. Even with these challenges, OEM is still useful for businesses that want quality and custom designs.

Note: Think about your budget and timeline before picking OEM. Be sure you’re ready for the work it involves.

Advantages and Disadvantages of ODM Manufacturing

Benefits of ODM for Speed and Cost Efficiency

ODM is great for saving time and money. The factory already has designs ready for you. You don’t need to create new ones. This helps you launch products faster and start selling quickly.

Another benefit is lower costs. Pre-made designs mean you skip expensive testing and prototyping. ODM works well if your budget is small. For example, if you sell toys or electronics, you can focus on branding while the factory makes the products.

ODM also helps grow your business. Ready-made designs let you make more products fast. You can meet demand easily. Plus, you can spend more time on marketing and customer service while the factory handles production.

Here’s a simple table showing ODM’s pros and cons:

Benefits | Limitations |

|---|---|

Less control over design | |

Saves money | Quality issues may happen |

Quick to market | Relies on factory’s skills |

Lower development costs | |

Easy to scale | |

Less risk | |

Focus on your strengths |

Tip: ODM is ideal for saving time and money. Make sure the factory meets your quality needs.

Challenges of ODM: Limited Design Control

ODM has some downsides. The biggest problem is less control over designs. You use pre-made ones, so you can’t change much. If you want something unique, ODM might not work for you.

Another issue is ownership of ideas. The factory owns the design, so you may face limits on how you use it. This can make it hard to stand out in a crowded market.

Quality can also be a concern. You depend on the factory’s skills, and mistakes in their process can affect your products. Picking the right ODM partner is very important.

Even with these challenges, ODM is still a good choice for businesses that need fast and cheap production.

Note: Think about your future plans before choosing ODM. If controlling designs and owning ideas matter, OEM might be better for you.

Comparing OEM vs ODM: Key Differences

Customization and Design Control

OEM lets you decide every part of your product. You pick the design, materials, and features. This helps your product match your brand perfectly. For example, if you’re making a smartwatch, you can choose cool features like heart rate tracking or a metal frame. OEM is great for making unique products that stand out.

ODM doesn’t allow much customization. The factory gives you pre-made designs. You can only make small changes, like adding your logo or changing packaging. This saves time and money but limits creativity.

Here’s a simple table to compare OEM and ODM:

Compared Differences | OEM Manufacturing | ODM Manufacturing |

|---|---|---|

Product Design | Customer Decides | Factory Decides |

Product Spec Sheet | Customer Provides | Factory Provides |

Product Advantages | Unique and Custom | Fast and Cheap |

Product Disadvantages | Expensive and Slow | Less Originality |

Tip: Choose OEM for full control and unique designs. Pick ODM for faster and cheaper production.

Intellectual Property Ownership

OEM gives you full ownership of your product’s design. You own the patents and ideas, so no one can copy them. This protects your brand and keeps your product special.

ODM doesn’t offer the same protection. The factory owns the design, and you just use it. This can be a problem if you want your product to be unique. For example, if you sell headphones, other companies might use the same design, making it harder to stand out.

Note: Think about your future plans. If owning your product’s design matters, OEM is the better choice.

Time to Market and Production Speed

ODM is faster because the designs are ready. You can launch your product quickly, which is helpful in competitive industries.

OEM takes longer since you need to design and produce everything. While this allows for custom products, it means waiting months before selling.

Callout: ODM is great for quick launches. OEM is better if you want custom products and can wait.

Cost Implications

When picking between OEM and ODM, cost is very important. You need to choose an option that fits your budget and business goals. Let’s look at the costs for both models to help you decide.

Upfront Costs

OEM needs more money at the start. You pay for designing, testing, and making tools. For example, creating a mold for a custom smartwatch can cost thousands. These costs add up fast, especially for unique products. But this spending gives you full control over design and quality, which can be worth it later.

ODM has much lower starting costs. The factory already has designs ready. You only pay for small changes, like adding your logo or changing packaging. This makes ODM a good choice for small businesses or startups with tight budgets.

Tip: If your budget is small, ODM is a smart choice. But if you want a unique product, OEM is worth the higher cost.

Production Costs

Making products costs more with OEM. You can pick better materials and processes, but this raises expenses. For example, using high-quality parts for a custom product costs more. However, this lets you create items that match your brand perfectly.

With ODM, production is cheaper. The factory uses standard designs and materials, saving money. But this also means you can’t make your product very unique.

Cost Factor | OEM Manufacturing | ODM Manufacturing |

|---|---|---|

Upfront Investment | High (design, testing, tools) | Low (small changes) |

Material Selection | Full control, higher costs | Limited options, lower costs |

Production Speed | Slower, custom processes | Faster, standard processes |

Long-Term Value

While ODM is cheaper at first, OEM can be better over time. With OEM, you own the design, so no one can copy it. This helps you build a strong brand and charge higher prices. Over time, the high costs can lead to more profits and loyal customers.

On the other hand, ODM saves money and helps you grow faster. You can launch many products without spending too much. But since you don’t own the design, other companies might sell similar products, which could hurt your sales.

Callout: Think about your future plans. If you want a premium brand, OEM is worth it. If speed and cost matter more, go with ODM.

Hidden Costs to Watch Out For

Both OEM and ODM can have hidden costs. For OEM, delays or mistakes in design can cost more money. Miscommunication with the factory can also cause problems. For ODM, quality issues or limited customization might hurt your brand, leading to lost sales or extra costs to fix problems.

Note: Plan for hidden costs in your budget. Good communication and picking the right factory can help avoid surprises.

In the end, the costs of OEM and ODM depend on your needs, budget, and goals. By understanding these factors, you can pick the best option for your business.

Choosing the Right Model for Your Business

Matching Manufacturing Models to Business Goals

Picking between OEM and ODM starts with knowing your goals. You need to choose a model that fits your business plan. Here’s how to do it:

Decide if you want custom products or quick, cheap solutions.

Break your plan into clear goals for teams and suppliers.

Set measurable targets, like production speed or product quality.

Use Key Performance Indicators (KPIs) to track progress.

Share KPI updates with your team to keep everyone informed.

Make changes fast if something isn’t working well.

Reward your team for meeting goals to encourage good work.

Tip: Think of your manufacturing choice as a tool. OEM is great for custom items, while ODM works for speed. Pick what helps your long-term goals.

Industry-Specific Tips for Consumer Products

The products you sell affect whether OEM or ODM is better. Different industries have unique needs. Here’s a simple guide:

Electronics: OEM is best for unique designs, like custom smartwatches. ODM is faster if you need quick launches.

Toys: ODM works well because factories have ready-made designs. You can brand them easily and save money.

Cosmetics: OEM lets you control details like ingredients and packaging. This is great for standing out. ODM is faster for beginners.

Callout: Each industry has different needs. Electronics, toys, and cosmetics require different approaches. Choose based on your market.

Budget and Cost Breakdown

Your budget is key when deciding between OEM and ODM. Let’s look at the costs:

Upfront Costs: OEM costs more at first for design and tools. ODM is cheaper since designs are ready.

Production Costs: OEM lets you pick materials, which can cost more. ODM uses standard materials, saving money.

Hidden Costs: OEM delays or mistakes can add expenses. ODM might have quality issues that cost extra to fix.

Here’s a quick cost summary:

OEM has higher material and design costs.

ODM includes factory costs like labor and materials.

Profits depend on your choice and market strategy.

Note: Check your budget carefully. Startups may prefer ODM for lower costs. Bigger companies might choose OEM for unique branding.

Scalability and Long-Term Strategy

Planning for your business’s future is very important. Two key things to think about are scalability and long-term strategy. Whether you’re starting small or growing bigger, the manufacturing model—OEM or ODM—you pick will affect your success. Let’s break it down to help you decide.

Why Scalability Matters

Scalability means how easily your business can grow. Imagine your product becomes very popular. Can your factory make enough to meet demand? If not, customers might go to competitors.

With OEM, you can adjust designs and improve quality as you grow. This gives you more control but costs more money and takes longer. ODM is faster for scaling because the designs are ready. You can quickly make more products, but you’ll have less room to create unique items.

Tip: Think about how fast you want to grow. If you need quick growth, ODM is a good choice. For steady growth, OEM might work better.

Building a Long-Term Strategy

A long-term strategy isn’t just about making more products. It’s about staying competitive, keeping customers happy, and adapting to changes. Here are some important factors successful companies focus on:

Factor | What It Means |

|---|---|

Market Trends | Knowing what customers want helps you plan ahead. |

Customer Loyalty | Happy customers keep coming back, like Amazon’s focus on service. |

Innovation | Adapting to new ideas, like Apple does, keeps you ahead. |

Sustainability | Using eco-friendly methods, like Patagonia, builds trust. |

Employee Growth | Training workers, like Google does, creates a strong team. |

Risk Management | Protecting your business, like banks do with cybersecurity, is key. |

Global Reach | Expanding worldwide, like Netflix, helps you grow. |

Smart Acquisitions | Buying other companies, like Facebook did with Instagram, can boost your market position. |

Data Use | Using data, like Walmart, helps manage stock and serve customers better. |

Continuous Improvement | Small, steady changes make businesses stronger over time. |

For example, if you sell electronics, being innovative is very important. OEM lets you make unique products that match trends. ODM helps you quickly meet market needs with ready-made options.

Callout: Companies like Apple and Patagonia show that innovation and sustainability can make you stand out. Think about how these ideas fit your goals.

OEM vs. ODM: Which Model Scales Better?

Both OEM and ODM help with growth, but in different ways. OEM gives you freedom to create unique products that match your brand. This is great for long-term growth and building loyal customers. However, it costs more and takes longer to scale.

ODM is better for quick growth. Pre-made designs let you increase production fast without spending too much. This is ideal for startups or fast-moving markets. But relying on ODM might make it harder to stand out later.

Planning for Sustainable Growth

Sustainability is not just a trend—it’s essential. Customers care about how products are made and their environmental impact. Whether you choose OEM or ODM, using eco-friendly practices can improve your brand’s image and attract buyers who care about the planet.

With OEM, you can pick green materials and work with factories that care about the environment. With ODM, you can choose suppliers who already use eco-friendly methods. Either way, showing you care about sustainability can help your business succeed.

Note: Being eco-friendly isn’t just good for the Earth—it’s good for business. Companies like Patagonia prove that green practices build customer trust and set you apart.

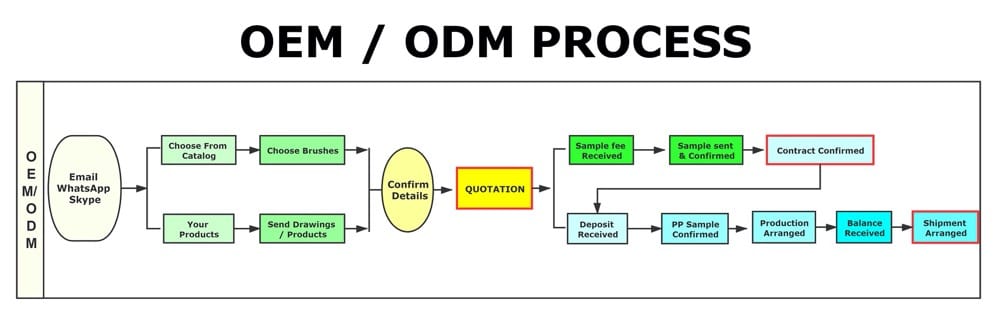

How Yansourcing Supports OEM and ODM Manufacturing

Yansourcing’s Expertise in Consumer Products Sourcing

Yansourcing makes finding products easy and efficient. With over 10 years of experience, they connect you with trusted suppliers for items like electronics and cosmetics. Their team ensures you get high-quality products that fit your needs.

For instance, skincare is growing fast in the cosmetics market. People want new items like anti-aging creams and natural products. Yansourcing helps you follow these trends by linking you with reliable manufacturers who offer affordable and consistent solutions.

Here’s why Yansourcing is unique:

They check quality to ensure your products meet top standards.

Their network includes factories skilled in both OEM and ODM.

They guide you on trends to keep you ahead of others.

Tip: Yansourcing’s expertise can save you time and money when sourcing products.

Tailored Solutions for OEM and ODM Manufacturing Needs

Yansourcing knows every business is different. They provide custom solutions to match your goals. Whether you need OEM for unique designs or ODM for quick production, they can help.

Their services include:

Finding the best factory for your product needs.

Helping create prototypes using tools like 3D printing.

Managing timelines so your products launch on schedule.

If you care about the environment, Yansourcing connects you with eco-friendly factories. This helps you make products that attract green-conscious buyers.

Callout: Yansourcing’s flexible approach works for startups and big brands alike.

Success Stories: BEFIT S1 Smartwatch Customization

Vietnam Mobile World wanted a smartwatch to compete with XiaoMi COLOR 2. Yansourcing made it happen. They customized the BEFIT S1 smartwatch with better heart rate tracking and local language support for Vietnam.

Here’s how Yansourcing solved their challenges:

Challenge | Solution Provided by Yansourcing |

|---|---|

Tight deadlines | Chose efficient factories |

Complex design needs | Improved design features |

Localization requirements | Added local language options |

The result? A top-quality smartwatch delivered on time, meeting all expectations. Vietnam Mobile World praised Yansourcing for their skill and professionalism.

Callout: Stories like BEFIT S1 show how Yansourcing turns ideas into success.

Conclusion

Deciding between OEM and ODM depends on your business needs. OEM lets you control designs and own ideas, but it costs more and takes longer. ODM is faster and cheaper, but you can’t customize much.

Aspect | OEM Pros | OEM Cons | ODM Pros | ODM Cons |

|---|---|---|---|---|

Control | Full control over product design | Designing is complex and time-consuming | Saves time and effort on design | Limited ability to make changes |

Time to Market | Slower due to design and tools | Launch takes much longer | Faster since designs are ready | Products lack uniqueness |

Cost | Higher upfront costs for design and tools | Needs more money and time | Fixed prices make costs clear | No ownership of designs, less exclusivity |

IP Rights | You own the design rights | Shared ownership can cause problems | N/A | N/A |

Matching your manufacturing choice to your goals can bring success. For instance, a dairy company boosted efficiency by 10%-12% and doubled equipment reliability by aligning processes with their goals.

Yansourcing makes this choice easier. Whether you need OEM for custom designs or ODM for quick production, they provide solutions to fit your needs. Their knowledge ensures quality products and smooth workflows, helping your business thrive in tough markets.

Ready to grow your business? Let us help you source products safely and efficiently. Visit Yansourcing to get started today.

FAQ

1. What is the main difference between OEM and ODM?

OEM gives you full control over product design, while ODM offers pre-made designs you can slightly modify. OEM is ideal for unique, custom products. ODM works best for quick and cost-effective production.

2. Can startups benefit more from ODM or OEM?

Startups often benefit more from ODM. It’s faster and cheaper, which helps you launch products quickly. OEM requires more investment and time, making it better suited for established businesses with larger budgets.

3. How do I protect my intellectual property with OEM?

With OEM, you own the product design and intellectual property. Ensure you sign contracts that clearly state ownership rights. This prevents the factory from using your design for other clients.

4. Is it possible to switch from ODM to OEM later?

Yes, you can switch from ODM to OEM as your business grows. Start with ODM to test the market. Once you have a steady customer base, invest in OEM for unique, branded products.

5. How does Yansourcing help with OEM and ODM?

Yansourcing connects you with reliable factories, manages quality control, and ensures smooth production. Whether you need custom OEM designs or quick ODM solutions, they tailor their services to fit your goals.