Polyester fabric is a man-made textile. It is made from polymers that come from petroleum. Many people and companies pick polyester because it is strong. It can be used in many ways. It is also cheap to make. Polyester fabric is important around the world.

If you’re a business owner, importer, or designer looking to source polyester fabric from China, understanding the basics of this material is essential.

In this guide, we’ll explore a complete overview of polyester fabric, including how it is made, its main properties, the different types available, and the various ways it is used.

Key Takeaways

Polyester fabric is strong, cheap, and easy to care for. It is made from polymers that come from petroleum.

To make polyester, raw materials are changed into fibers. This happens through polymerization, melting, and spinning steps.

Polyester is used a lot in clothes, home items, and industry. People like it because it lasts long, does not soak up water, and does not wrinkle.

Recycled polyester helps cut down on waste and saves energy. New technology tries to make making polyester better for the environment.

If you work with trusted suppliers like Yansourcing, you get good polyester fabric. This also makes getting what you need easier.

Polyester Fabric Overview

What Is Polyester Fabric?

Polyester fabric is a very common synthetic textile. It is made by changing petroleum into strong and bendy fibers. People use polyester in clothes, things for the home, and even in factories.

Polyester is liked because it does not wrinkle easily. It dries fast and keeps its shape after many washes. Many brands pick polyester since it costs less and is simple to take care of.

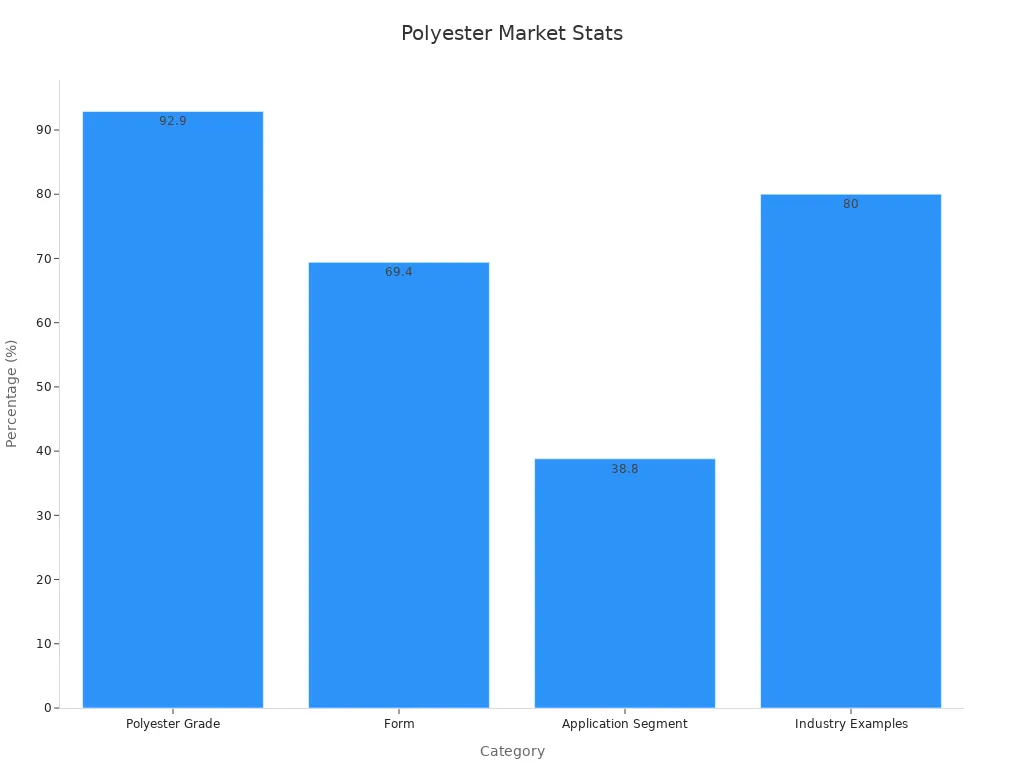

The polyester market is getting bigger every year. Companies use polyester staple fiber and polyester filament yarn in lots of items. The table below gives important facts about the polyester business:

Aspect | Details |

|---|---|

Market Size (2022) | USD 3,361.98 million |

Market Size (2030) | USD 5,545.68 million |

CAGR (2023-2030) | 6.2% |

Key Segments | Staple Fiber, Filament Yarn, Virgin, Recycled, Blended, PET, PCDT, Solid, Hollow |

Applications | Carpets, Non-Woven Fabrics, Apparel, Home Textiles, Others |

Regional Insights | Asia-Pacific leads due to strong textile industry and infrastructure |

Major Players | Reliance Industries, Toray Industries, Indorama Ventures, Sinopec Yizheng Chemical Fiber, and more |

Market Drivers | Textile demand, carpets, urbanization, home décor |

Market Restraints | Regulations, environmental concerns |

Recent Developments | Sustainability efforts, wastewater treatment improvements |

Origins and Composition

Polyester started in the early 1940s. Wallace Carothers worked at DuPont and studied synthetic polymers in the 1920s and 1930s. He found the polyester compound called polyethylene terephthalate (PET) in 1931.

In 1941, Whinfield and Dickson, who were British chemists, made the first polyester filament. This was the beginning of making polyester fiber.

Polyester is made from ethylene that comes from petroleum. Factories turn this into a thick liquid. They spin the liquid into fibers using melt spinning. Each polyester strand is made by a chemical reaction, not from plants or animals.

Polyester used to be rare and expensive. Now it is common in textiles. Today, polyester products are everywhere. They last a long time, do not stain easily, and are a good deal.

How Is Polyester Fabric Made?

Raw Materials

Polyester fabric begins with materials from petroleum. Factories use ethylene glycol and terephthalic acid. These chemicals come from oil and gas. Some companies use recycled plastic bottles. Others use biobased sources like sugar cane.

Textile Exchange is a group that tracks these materials. They set rules for recycled content. Their reports show most polyester still uses new fossil-based sources.

But recycled polyester is growing quickly. Factories must pick good raw materials. This helps make strong and reliable polyester fibers.

Polymerization Process

Making polyester fabric starts with a chemical process called polymerization. This process has two main parts. First, ethylene glycol reacts with terephthalic acid. This makes ester bonds and gives off water. The water is taken away to keep the reaction going.

Next, polycondensation happens. Small molecules join to make long chains of PET. More water comes out during this step. The result is a thick, sticky PET polymer.

This material makes polyester strong and able to resist moisture and heat. These reactions need high heat and pressure. Factories control the process to keep PET pure and ready for making fibers.

Fiber Production

Factories turn PET polymer into polyester fibers in several steps. The PET cools and is cut into small chips. Workers dry the chips to remove water.

The chips melt at about 260°C. The melted PET goes through spinneret holes. This forms long filaments. The hole size controls fiber thickness.

Process Stage | Technical Details |

|---|---|

Raw Materials | Ethylene glycol and terephthalic acid from petroleum or recycled sources. |

Polymerization | Esterification and polycondensation create PET polymer chains. |

Polyester Chips | PET cooled and cut into chips for easy handling. |

Extrusion | Chips melted and pushed through spinnerets to form filaments. |

Cooling | Filaments cooled quickly to set their structure and strength. |

Drawing | Fibers stretched to improve tenacity and uniformity. |

Crimping | Mechanical crimping adds texture and bulk. |

Dyeing | Disperse dyes applied at high temperatures for color. |

Quality Control | Factories check denier, strength, and elasticity to ensure high-quality polyester fibers. |

Workers can cut filaments short to make staple fibers. Or they can leave them long for filament yarns. Factories control heat, water, and air to keep fibers strong and smooth.

Fabric Manufacturing

The next step is turning fibers into fabric. Factories use spinning, weaving, or knitting machines. Spinning twists fibers into yarn. Weaving and knitting turn yarn into fabric sheets. Modern machines work fast and make lots of polyester fabric.

Testing standards like ASTM and AATCC check the quality. After dyeing, fabric may get heavier and thicker. Dyeing can also change fabric strength and how it wears out.

Polyester blends, like polyester/cotton or polyester/bamboo, act differently after dyeing. For example, polyester/bamboo blends stay stronger than polyester/cotton blends after dyeing.

Parameter | Measurement/Effect | Statistical Evidence/Notes |

|---|---|---|

Mass per unit area (g/m²) | Increases after dyeing | Dyeing causes shrinkage and weight gain |

Bursting strength | Decreases after dyeing; higher in polyester/bamboo blends | Paired t-test shows significant impact except for polyester/bamboo blend |

Abrasion resistance | Reduced in dyed samples, especially with yellow dye | Statistically significant effect (p ≤ 0.05) |

Air and water permeability | Slightly affected by dyeing | Measured by ASTM standards |

Structural properties | Weight, thickness, stitch density, and loop length change after dyeing | Bamboo/polyester blends more affected |

Most polyester fabric is made in China, India, and Southeast Asia. Yansourcing helps companies get good polyester fabric from China. Their team checks every step, from picking raw materials to checking the finished fabric.

They handle shipping and quality checks. This helps clients get strong and reliable polyester fabric for any use.

Tip: Working with a sourcing expert like Yansourcing helps make sure every batch of polyester fabric is high quality and arrives on time.

Properties of Polyester Fabric

Durability and Strength

Polyester is known for being very strong. The fabric stays tough after many washes and years of use. Tests in labs show polyester keeps high bursting and tensile strength. For example, new samples can reach 430 kPa for bursting strength and 224 N for tensile strength.

Even after 36 months, the fabric is still strong. The numbers only drop a little. The table below shows how polyester does in different tests:

Test Type | New Unwashed | Laboratory-washed | 36-month-old |

|---|---|---|---|

Fabric Weight (g/m²) | 47.2 | 45.8 | 48.2 |

Bursting Strength (kPa) | 430 | 390 | 376 |

Tensile Strength (N, length) | 224 | 210 | 196 |

Mesh Size (holes/cm²) | 31 | 29 | 30 |

Polyester fibers do not tear or stretch easily. The fabric keeps its shape and thickness even as it gets older. This is why polyester is picked for things that need to last a long time.

Moisture Resistance

Polyester fabric does not let water in easily. The fibers stay dry and light, even when it is humid. Tests show that regular polyester takes in less than 1% water. Some treatments can make it take in more, but most polyester stays dry.

If coated with minerals, it can hold more water, but the main polyester still resists moisture. This helps clothes dry fast and keeps people comfortable.

Wrinkle and Stain Resistance

Polyester does not wrinkle or stain easily. The fibers do not bend or fold like cotton or linen. Clothes made from polyester stay smooth and neat without ironing. The fabric also pushes away water, so stains do not stick.

This is why polyester is used for uniforms, sportswear, and outdoor clothes. The fabric keeps its color and looks new after many uses. People like polyester because it is easy to care for and looks good for a long time.

Types of Polyester Fabric

PET Polyester

PET polyester is the most common kind of polyester fabric. Factories make it from polyethylene terephthalate. This fabric is very strong and does not wear out fast. It does not break down or get damaged by many chemicals.

PET polyester feels smooth and keeps its color after many washes. People use it for luggage, outdoor gear, and things made in factories. It is cheap to make, so companies like to buy a lot at once.

PCDT Polyester

PCDT polyester has different features than PET. It is made from poly-1,4-cyclohexylene-dimethylene terephthalate. PCDT polyester can stretch more than PET. It goes back to its shape after you pull or twist it.

This fabric is good for things that must keep their shape, like curtains and furniture covers. PCDT costs more than PET, but it is more stretchy and keeps its shape better. Factories pick PCDT when they need fabric that is both flexible and strong.

Blended Fabrics

Blended fabrics mix polyester with other fibers like cotton. These blends give you the best parts of each fiber. Polyester-cotton blends are soft and let air move through them. They also do not wrinkle much and last longer than just cotton.

Many uniforms and accessories use these blends. The price is between low and medium, depending on what is mixed in. Buyers look for certifications like OEKO-TEX or GOTS, especially if the blend has organic cotton.

Fabric Type | Key Properties and Differentiators | Typical Applications | Cost Level |

|---|---|---|---|

PET Polyester | High durability, strong tensile strength, chemical resistance, non-biodegradable | Luggage, outdoor gear, industrial textiles | Low |

PCDT Polyester | Enhanced elasticity, shape retention, superior stretch and recovery | Upholstery, curtains, flexible goods | Medium |

Polyester-Cotton Blends | Durability, wrinkle resistance, breathability, comfort | Apparel, uniforms, accessories | Low to Medium |

Note: Testing standards like ASTM and ISO help check the quality of all types of polyester fabric. Certifications are important for blended fabrics, especially in clothes.

How Is Polyester Fabric Used?

Clothing and Fashion

Clothing is the biggest use for polyester. Brands like polyester because it is strong and cheap. It is easy to take care of. You can find polyester in t-shirts, dresses, jackets, and sportswear. The fabric does not wrinkle and dries fast. This makes it great for sports clothes and fast fashion.

Reports say polyester is over half of all textile fibers in the world. In 2024, clothes and apparel use about 49.3% of all polyester. Big companies like Nike and Patagonia use recycled polyester now. They want to help the environment.

Polyester is strong and keeps its color well. It can mix with other fibers for comfort and style. These things help brands make clothes that last and do not cost much.

Source / Study | Polyester Usage in Apparel and Fashion Industry | Notes |

|---|---|---|

Fashion For Good & Circle Economy (2022) | ~20% polyester in apparel and home textiles | Waste composition study in Europe |

Re_Fashion (2023) | ~19% polyester in apparel and home textiles | Sorting facility streams study |

Sustainability Reports (12 major brands, 2022-2023) | 26-30% polyester average | Volume-weighted closer to 30% polyester |

Textile Exchange (2024) | Claimed 47 million tonnes polyester used in apparel & home textiles (~56%) | Considered an overestimation by author |

European Commission JRC (2023) | Polyester sub-30% in most apparel categories | Based on production and import statistics for EU market |

Shein e-commerce study | Over 80% of products contain polyester | Polyester-containing products, not necessarily 100% polyester |

Yansourcing helps brands get many kinds of polyester fabric for clothes. This helps them meet their design and quality needs.

Home Textiles

Polyester is used a lot in home textiles. People pick polyester for curtains, bed sheets, couches, and tablecloths. The fabric does not stain easily and is safe from fire. It is also simple to clean. There are many designs and finishes to choose from.

In 2023, the home textile market was worth $124.72 billion. Polyester is a big part of this market. People want nice and useful home items as incomes rise and lives change.

Polyester is cheap, lasts long, and can be used in many ways. Yansourcing helps businesses get good polyester fabric for all home textile needs.

Polyester looks good in modern homes and fits many styles.

It is strong and easy to clean, which is good for busy families.

Online shopping makes it easier to buy polyester home textiles.

Industrial Applications

Polyester is used in many industries. It is strong and does not get damaged by chemicals. This makes it good for conveyor belts, ropes, and tough fabrics.

Polyester does not soak up water or grow mold. It works well in packaging, car seats, and outdoor gear. Because it is light, it helps make cars lighter and saves fuel.

Polyester is cheap, works well, and can be recycled. This is good for the environment. Yansourcing helps clients find polyester fabric that meets tough industry rules.

Note: Polyester fabric is used in clothes, homes, and industry. Its low cost, strength, and many uses make it a top pick for many companies.

Environmental Impact

Sustainability and Recycling

Polyester fabric affects the environment in many ways. Many companies now want to be more eco-friendly. They use recycled polyester to cut down on waste and save resources.

Recycled polyester is made from old plastic bottles and used clothes. This helps lower the need for new petroleum and reduces carbon emissions. Factories also try to use less energy and use solar or wind power.

Recycled polyester uses fewer new resources and keeps plastic out of landfills.

Some companies are testing bio-based and biodegradable polyester to help the planet.

Factories improve machines and use cleaner methods to make less pollution.

Some join carbon offset programs, like planting trees or using green energy.

Closed-loop recycling and chemical recycling help reuse polyester many times.

People can help by buying certified recycled polyester, using laundry filters for microplastics, and joining recycling programs.

There are problems like high costs, low awareness, and technology limits. Solutions include government help, teaching people, and more research.

Recycled polyester helps fix some problems, like plastic waste and high energy use. But polyester still causes microplastic pollution and breaks down slowly in nature. More work is needed to make polyester better for the environment.

Innovations in Polyester Production

New technology helps lower polyester’s harm to the environment. Companies spend money on cleaner ways to make polyester, but it can cost a lot.

Some buyers pay more for green products, but most care about style and price. Clear rules and better reports help people know the real impact.

Technology/Innovation | Description | Environmental Impact |

|---|---|---|

Bio-based raw materials (bio-PET) | PET made from plants, not oil. Cuts carbon emissions by 82%. | Lowers greenhouse gases and fossil fuel use. |

Biodegradable polyesters (PHAs) | Made by microbes. Breaks down in soil and water. Can be recycled chemically. | Reduces plastic pollution by turning into CO2 and water. |

Improved recycling technologies | Better ways to recycle polyester. | Raises recycling rates above 14%, cuts waste and saves resources. |

Use of biomass waste | Uses corn straw or wood waste, not food crops. | Avoids food competition and supports green sourcing. |

Advancements in catalytic systems | New processes make bio-PET cheaper and easier to produce. | Makes sustainable polyester more affordable and common. |

Governments now make new rules, like digital product passports and eco-design laws, to push for better sustainability. Companies track climate data to show their products are better for the planet. These steps help fix polyester’s problems and move the industry toward a greener future.

Conclusion

You now have a clear understanding of polyester fabric—its strength, versatility, and how it’s made from both new and recycled materials. This knowledge helps you address the common challenge of finding high-quality, sustainable polyester that meets your brand’s needs.

As the demand for eco-friendly polyester grows, with energy-saving recycled PET and certifications like GRS and OEKO-TEX gaining importance, it’s crucial to partner with experienced sourcing experts. Companies like Yansourcing ensure you get reliable, certified fabric while supporting your sustainability goals.

Next, take the step to connect with a trusted sourcing partner who can guide you through the process of importing quality polyester fabric from China.

FAQ

1. What is the best way to wash polyester fabric?

Wash polyester using cold or warm water. Pick a gentle cycle on your washing machine. Turn your clothes inside out before washing. Do not use bleach. Dry on low heat in the dryer or hang them up. Polyester dries fast and keeps its shape well.

2. Does polyester fabric shrink or fade?

Polyester does not shrink or fade easily. The fibers keep their color for a long time. High heat can hurt the fabric, so always use low heat when drying or ironing.

3. Is polyester fabric safe for sensitive skin?

Most people can wear polyester with no trouble. Some people with very sensitive skin may feel itchy. Blends with cotton or bamboo are softer on the skin.

4. Can Yansourcing help with custom polyester fabric orders?

Yansourcing works with many different suppliers. They help clients get special colors, patterns, and finishes. Their team checks the quality and handles shipping for each order.

5. How does recycled polyester compare to regular polyester?

Recycled polyester is made from old plastic bottles or clothes. It looks and feels like regular polyester. It helps cut down on waste and saves energy. Many brands now pick recycled polyester.