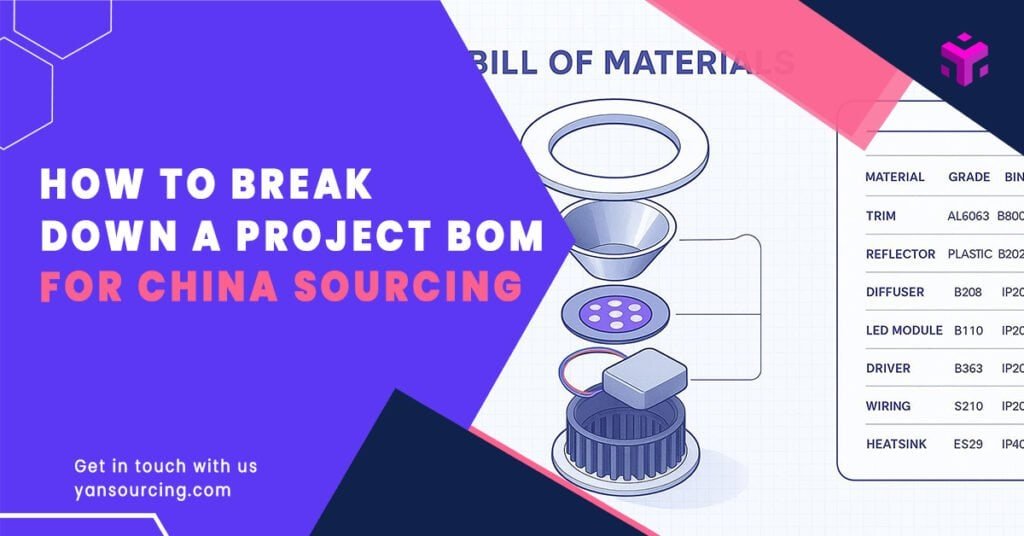

Ambiguous specifications are an open invitation for factory substitutions—and that’s where cost, performance, and compliance problems begin.

If you’re buying recessed LED downlights for a building project, a substitution-proof, engineering-grade BOM is your first line of defense.

This tutorial shows how to structure that BOM so suppliers can’t “fill in the blanks,” and your team can lock quality, compliance, and total cost from RFQ through delivery.

EBOM vs MBOM: Where substitutions creep in

The Engineering BOM (EBOM) defines the product as engineered—materials, grades, ratings, photometrics, and test references.

The Manufacturing BOM (MBOM) defines how the factory builds—sub-components, process steps, fasteners, torque, and packaging.

Think of EBOM as the design truth and MBOM as the build recipe.

Substitutions creep in when the EBOM leaves brand/model or performance ranges open (“LED module: 3000–4000K, 800–1000 lm”) and the MBOM doesn’t specify process controls (“TIM: TBD; torque: TBD”).

In China sourcing, “TBD” is a cost-saving magnet.

Lock the EBOM fields first, then cascade MBOM controls to each factory node.

The LED downlight BOM—field-by-field template

Below is a compact template you can mirror in your sheet or PLM. Replace ranges with exact values and report numbers. If a brand/model is not negotiable, write “No alternates without written ECN.”

| Section | Field | Spec example (write exact values) |

|---|---|---|

| Mechanical | Heatsink alloy/temper | 6063-T5, anodized 12–15 µm, black matte; fin thickness ≥ 2.0 mm |

| Mechanical | Trim/reflector | Die-cast aluminum, powder coat RAL XXXX, gloss ≤ 10 GU; anti-glare baffle |

| Mechanical | Fasteners | SUS304, M3×8, torque 0.6 N-m; thread-locker Loctite 243 |

| Mechanical | Mounting | Spring clips, stainless; ceiling thickness 10–15 mm; cutout Ø90 mm |

| Optical | LED package/module | Brand/Model: Nichia 757 or Cree XHP; Bin: CCT 3000K ±100K, CRI ≥ 90, flux bin XX |

| Optical | Optics | TIR lens 24°; diffuser PMMA haze 70% |

| Electrical | Driver | Brand/Model: Inventronics EUM-XX; PF ≥ 0.90; THD ≤ 15%; dimming: 0–10 V or DALI |

| Electrical | Wiring | 0.75 mm² (AWG 18) silicone insulation, 300 V, 150 °C; color code per IEC |

| Electrical | Connectors | WAGO 221 or equivalent, UL/EN listed; earth bonding point specified |

| Thermal | TIM | Graphite pad 0.3 mm, k ≥ 8 W/m-K; coverage ≥ 95% contact area |

| Compliance | EU | CE: LVD 2014/35/EU, EMC 2014/30/EU, RoHS 2011/65/EU; EN/IEC 60598-1 and -2-2 |

| Compliance | US | UL 1598, UL 8750 (NRTL listed); FCC Part 15 Subpart B; IC rating required (if applicable) |

| Ratings | IP/IC | IP44 trim; IC-rated for insulation contact; ambient 0–40 °C |

| Performance | Photometrics | LM-79 report ID XXXXX; luminous flux ≥ 800 lm; efficacy ≥ 75 lm/W; IES file attached |

| Performance | Source lifetime | LM-80 report IDs; TM-21 L70 ≥ 50,000 h at Tsp ≤ 85 °C |

| Performance | Flicker | Meets IEEE 1789 guidance; modulation depth limits documented; dimming method disclosed |

| Documentation | Labels | CE, WEEE, UL/ETL, FCC SDoC statement; COO: Made in China; model/serial/lot per IPC-1782 |

| Packaging | Carton | Double-wall 44 ECT; foam inserts EPE 35 kg/m³; BMC with ECT; ISTA transit test reference |

Notes on key references

- Luminaire safety and particular recessed requirements in the EU: specify EN/IEC 60598-1 and 60598-2-2 under CE conformity. See the IEC publication overview for IEC 60598-1 general luminaire safety.

- US safety and EMC: require listing to UL 1598 and UL 8750 by a Nationally Recognized Testing Laboratory, plus emissions compliance to FCC 47 CFR Part 15.

- LED source data: lock LM-80 report IDs and TM-21 projections. For context on LM-80 methodology, see the DOE explainer “Lumen and Chromaticity Maintenance of LEDs”; TM-21 projection rules are summarized by IES in TM-21-21.

- Whole-luminaire photometrics: request an LM-79 report for your exact configuration and ensure the IES file metadata matches that setup.

- Flicker guidance: specify performance aligned with IEEE Std 1789-2015 recommended practices.

- AQL sampling basics: embed ISO 2859-1/ANSI Z1.4 parameters. Practical explainers include QIMA’s AQL guide.

- Carton strength: ECT is measured per ISO 3037/TAPPI T811/T839; validate packaging with ISTA transit programs. See ISTA program overview.

Lock performance and compliance in the BOM (so they can’t be “interpreted”)

Performance isn’t a promise—it’s a set of measured reports. In your BOM, reference exact report IDs and conditions:

- LM-80 source data: “LED package Cree XHP35, LM-80 report ABCD, test temps 55/85 °C, drive current 350 mA.”

- TM-21 projection: “L70 ≥ 50,000 h projected per TM-21 using above LM-80 data; thermal set-point Tsp ≤ 85 °C.” Note that TM-21 is a projection, not a warranty.

- LM-79 luminaire data: “Report ID EFGH for the configured downlight with 24° TIR lens, input 120 V, 60 Hz; PF/THD values recorded.”

- IES file: attach the IES photometric file and require the lab’s metadata to match the LM-79 test configuration.

- Flicker: require disclosure of dimming method (PWM frequency or CCR) and compliance with IEEE 1789 guidance at your operating ranges.

For compliance, separate luminaire-level CE/UL conformity from component claims:

- EU: declare LVD/EMC/RoHS at the luminaire level, tested against EN/IEC 60598-1/-2-2 and relevant EMC standards. Control gear should conform to EN/IEC 61347 series.

- US: require UL 1598/8750 listing for the exact model by UL or Intertek (ETL). For EMC, document the device category under FCC Part 15 and include the SDoC statement in labels/manuals.

Build the QC plan inside the BOM: sampling and checkpoints

Don’t bolt QC on later—bake it into the BOM.

- Sampling plan: “ISO 2859-1/ANSI Z1.4, Inspection Level II by default; Critical AQL 0.0; Major AQL 0.65; Minor AQL 2.5.” State the lot size-to-sample size code letters and Ac/Re numbers for common lot sizes your project uses.

- Switching rules: call out when to move to tightened inspection (e.g., two consecutive lots near rejection) and reduced when stable.

Critical checkpoints to specify:

- Incoming verification: driver make/model/spec; LED brand/model/bin aligns with LM-80 source; wire gauge/insulation; connectors; fastener grade.

- Assembly controls: thermal interface material type/thickness; heatsink alloy/finish; torque values; strain relief; earth continuity points.

- Electrical safety: dielectric/hi-pot, earth continuity, polarity; functional test and burn-in (e.g., 2–4 hours).

- Performance: lumen/CCT verification vs spec; flicker test; optics alignment; IES file consistency if photometric sampling is performed.

- Environmental: IP44 or other ratings validated where applicable; temperature rise test conditions documented.

If your project is large, assign these checkpoints to specific nodes (die-caster, LED package supplier, driver factory, cable/connector vendor, final assembly) with acceptance documentation required from each.

Packaging and labeling specs that prevent damage and delays

Set packaging as a spec, not an afterthought.

- Corrugated: “Double-wall 44 ECT; flute BC; liners: kraft 200 gsm; humidity conditioning per ISO/TAPPI prior to test.”

- Cushioning: “EPE 35 kg/m³; drop test per ISTA 1A or project’s chosen protocol; corner/edge protection required.”

- Validation: distinguish ECT (material) from box compression (BCT) and transit tests. Require an ISTA program reference and pass/fail criteria.

- Labeling: product labels must include CE, WEEE, UL/ETL listing marks, FCC Part 15 statement (for SDoC), model/serial/lot, and Country of Origin per 19 CFR Part 134.

- Palletization: specify pallet type, stacking pattern, tie sheets, stretch-wrap, corner boards, and max stack heights under warehouse climate.

For authoritative context on transit validation, see ISTA program standards.

Change control and multi-factory coordination

Uncontrolled changes are the fastest path to substitutions. Put a gate in front of every change:

- ECN/ECR workflow: define who can propose changes, impact analysis steps, and approval signatures. Version your BOM and keep an approved alternates list.

- Golden samples: seal physical samples (trim, heatsink, LED module, driver, optics) and retain them at both buyer and factory; use them during incoming and pre-shipment inspection.

- Traceability: adopt IPC-1782 data elements—serial/lot coding that ties components to finished goods. Require traceability on labels and in production records.

Cascade critical-to-quality (CTQ) requirements to each factory: die casting (alloy/finish/tolerances), CNC (flatness, thread quality), LED package supplier (brand/bin), driver factory (PF/THD/dimming), cable/connector (gauge/insulation/listing), packaging plant (ECT/BMC/label content).

Mini workflow example (with one neutral agent role)

Here’s the deal: you issue the RFQ with the BOM table above filled to the letter. The LED supplier returns LM-80 data; the luminaire maker provides LM-79 and IES files; the driver vendor confirms PF/THD and dimming protocol.

At verification, a sourcing partner can help stitch the evidence together: confirming the LM-80 source aligns with your TM-21 projection and the luminaire’s thermal path, checking FCC Part 15 SDoC placement, and setting up the AQL sampling sizes and checkpoints.

Common mistakes (and quick fixes)

- “LED brand/model/bin not specified.” Fix: lock brand/model plus bin codes; quote LM-80/TM-21 references in the BOM.

- “Driver PF/THD/dimming left open.” Fix: state PF ≥ 0.90, THD ≤ 15%, protocol (0–10 V/DALI), and exact model.

- “Heatsink alloy/finish vague.” Fix: specify 6063-T5 vs 6061-T6, anodization thickness/class, and torque values.

- “Wire gauge/insulation missing.” Fix: set AWG/mm², insulation rating (temp/voltage), and applicable standard.

- “LM-79/IES files not requested.” Fix: demand whole-luminaire LM-79 report and matching IES file.

- “Packaging ECT unspecified.” Fix: set ECT, cushioning type/density, ISTA program, and include BMC details.

- “No lot traceability.” Fix: require IPC-1782-style serial/lot coding and retention of records.

Final BOM validation checklist

- EBOM fields filled with exact brand/model/spec values; “No alternates without ECN” noted where needed.

- LM-80/TM-21 source data referenced; LM-79 and IES files attached for exact configuration.

- CE/UL/FCC compliance mapped at luminaire level; component standards referenced appropriately.

- AQL sampling plan and checkpoints embedded; Ac/Re numbers prepared for typical lot sizes.

- Packaging spec set: ECT, cushioning, ISTA validation; palletization rules defined; labels include CE/WEEE/UL/ETL/FCC and COO.

- Change control live: ECN/ECR workflow defined; golden samples sealed; traceability in place.

Lock these into your BOM, and you’ll reduce rework, keep installations on schedule, and stop substitutions before they start.

At the end of your BOM workflow, if you want a sourcing team that can lock specs, control substitutions, and manage multi-factory coordination end-to-end, get expert support from Yansourcing.