Toys are often considered to be fun, off-the-cuff items that provide to kids to keep them satisfied and happy.

However, the toy manufacturing process is very complex. Starting with the idea and ending with the finished product, you need to talk to a network of experts at each step.

In today’s post, we’ve compiled a step-by-step guide to the toy manufacturing process. Keep reading to learn everything you need to know to bring your own toys to market.

What Is a Toy?

Toys are usually objects designed for kids primarily for play, and toy play can be an enjoyable way for young kids to prepare for real-life situations.

Playing with toys can be an enjoyable means of training young kids to adapt to social life. Toys are made of various materials, such as wood, clay, paper, and plastic; simple examples are blocks and dolls.

However, there are also many toys explicitly designed for adults and pets in specific situations, and some toys are mainly produced as collectibles and are only used for display.

The Benefits of Buying Toys for Your Kids

Every kid should have a toy in their early years. The impact of the toys you choose for them in those early years will likely stay with them for the rest of their lives and help them develop key abilities later in life.

Here are the benefits of buying toys for your kids:

1. Enhancing cognitive abilities

Many toys that involve constructive play, support, and strengthening numeracy or literacy skills provide opportunities to stimulate cognitive development.

For example, a certain type of wooden toy allows a kid to improve his cognitive ability of these things through numbers, letters, shapes, etc.

2. Improves IQ and memory

It raises IQ and makes learning enjoyable. Memory retention, motor skill development, coordination, literacy, and numeracy are all areas where educational toys can help kids improve their IQ.

3. Creative thinking and improved concentration

Toys encourage youngsters to use their creativity when playing, creating situations, and solving problems.

Toys can stimulate greater creative thinking, and kids will create rich imaginary scenarios when using toys, using their imagination to provide soothing and focused activities.

Improve concentration. Kids have short attention spans and can quickly lose interest or become distracted from an activity, especially if it’s something they don’t like.

Toys make things that kids may find tedious, such as math or language instruction, into an enjoyable experience.

4. Improve their problem-solving skills

The potential of toys to challenge kids to think is one of their most important strengths. Kids can use magnetic educational puzzles, for example, to help them think through how to solve a problem.

They can use the puzzle toys to figure out which piece goes where through trial and error, get problem-solving skills and find joy in playing with the toys.

5. Increase parent-kid communication and interaction

Toys have a positive impact on the communication between parents and kids.

Because toys can increase the interaction between parents and kids, they can participate in their toy games together and increase the participation of parent-kid games.

And they can develop kids’ language and communication skills during toy play. It also provides children with greater fun and enhanced happiness and security during interactive play.

What Is the First Step In the Toy Manufacturing Process?

Toy-making is a complex process that starts with conception and ends with execution. At each step, there is a network of experts you need to turn to.

The first step in making a toy is having the most important idea, which is coming up with an idea that develops creatively.

Does the new toy idea make sense, and is it a good marketing idea? This is important.

1. How do you make sure your idea is a good one?

The idea must be unique and marketable. Remember how vast the toy market is and how much competition there is. You need to know what the market looks like before entering it properly.

For example, the Toy Fair in New York City has upwards of 7,000 toy ideas each year. Of those 7,000 ideas, about 1,000 are produced by experts with a lot of information at their fingertips. Everything they do is to make interesting toys.

Therefore, you also have to do formal and informal research. Read trade magazines, especially those that are published immediately after toy fairs. This can help you determine if your idea is unique and industry trends.

The following magazines are very popular in the industry:

- Educational Games Magazine

- aNb Media

- Adventure Publishing Group

Although future trends are hard to predict, you can make a market-oriented idea by knowing what’s going on now.

There are a few more questions worth asking:

- Will the product sell?

- How long will it last?

- Does the toy need to be replaced?

- How easily do they grasp the concept of using it?

- How long does the average play session last?

These questions can be better answered using focus groups, design testing, and talking to parents and their kids.

This can help you determine if there is a demand for it now and how much growth potential there can be for this product.

The more time you spend on research, the better, but ensure you don’t miss the opportunity to design a product through endless information gathering.

Sooner or later, you must decide if your product is viable. It’s okay if your first idea doesn’t make it past this stage, because the information gathered will help build an informed design for the future.

2. Is it cost-effective?

It is critical to calculating the cost of your product. Do you need to consider at what price you want to enter the market?

So make a prototype and see if it is cost-effective. Depending on the accounting method, you can calculate how much it would cost to make a prototype.

This price must be comparable to other products in the same category in the market. If your price is competitive, your product will sell.

If the toy needs to be replaced or requires additional replacement parts to keep it functioning, the upfront cost may not justify such a high price, while a one-time purchase may require a higher entry price if the item is durable.

You may want to contact the toy manufacturer for a price estimate, depending on what toy you want. Plastic toys or toys that require complex processes require contacting a toy manufacturer.

To produce toys at a reasonable cost, sell them at a competitive price, and make a profit, you should consider the entire cost, from manufacturing to marketing.

Costs can also be determined by competition in the marketplace. For example, game consoles can demand higher prices thanks to little competition and market share distribution among various companies.

3. Is it safe?

There are rules and regulations regarding the safety of new toy manufacturing. Industry trade groups, such as the Toy Association, keep toy safety standards up to date and can give you more tips.

And they must be followed at every step of the manufacturing process. Once you know who your product is intended for, you will know exactly what standards your product needs to meet.

For example, small parts in toys designed for babies may be restricted, depending on the country where you manufacture and sell them. A non-toxic manufacturing process may also be critical.

Different safety rules depend on what you do and where you are. When making toys, the safety of children is the most important thing.

4. Legal protection

Patents and trademarks are legal protections. Know what they are so you can make your toys. Conducting a patent search is the first step to obtaining a patent.

So you need to establish that a patent or trademark is important in protecting your intellectual property.

The first step will involve a patent search. This will mean hiring a legal professional who can work with a patent database to ensure that you are not infringing on the legal protections of others.

The attorney conducts a patent search to ensure that no one else has filed a patent for the same thing.

Without this step, conducting a market study would be impossible because the toy company would patent toys that have not yet entered the market.

In addition, Toys for Tots has a range of resources to help you determine how to avoid IP infringement when designing your product.

5. Know who you are trying to reach

Knowing your target audience is critical. Determine what age group and gender your target audience belong to and what other interests they enjoy most.

If your kid plays with dolls, he’ll probably like stuffed animals, too. Marketers and packagers need to know who their target audience is.

Marketing and packaging efforts will be more successful if you categorize your target audience based on the aesthetic that most appeals to them. This will help to calculate a reasonable price and production cost.

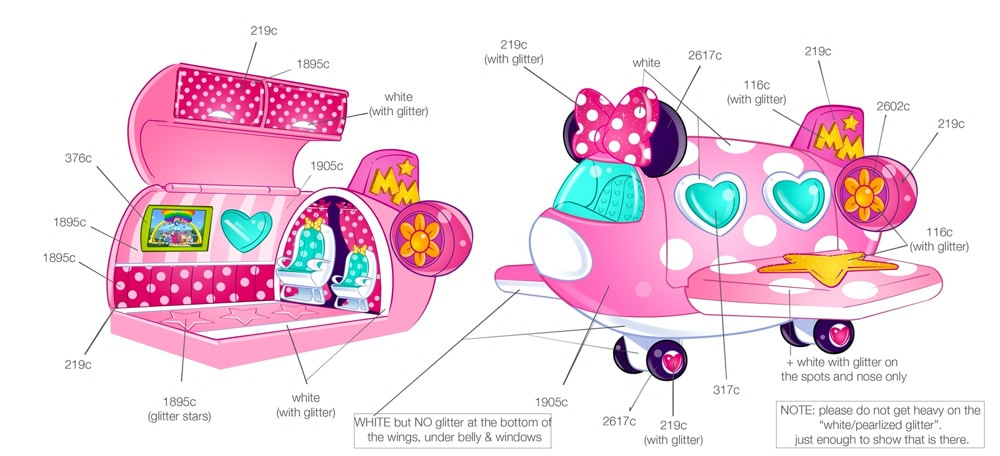

6. Final design

After planning all the prior necessities, you can begin the final design process.

Determining the materials you will use to design the product, the safety features you will implement, ensuring compliance, and branding your product appropriately are the basic steps to consider here.

The final design will also include decisions related to the name of the product, the colors it may use, and of course, the user experience design.

UX design is a discipline dedicated to making any product more accessible and understandable to its target audience.

For toys, this means identifying how people interact with a product, defining the likelihood that people will encounter that feature and how it can help your product, or how it must reduce the likelihood of that happening.

UX design is a complex process that some companies choose to outsource. The final design will include a detailed planning phase.

You will then prepare sketches and 3D renderings of the toy to ensure it is feasible for manufacturing and that the design is realized in 3D space.

From there, outsourcing the manufacturing company to your prototype can be proof of concept that will help you move confidently into the manufacturing process.

How Does the Toy Manufacturing Process Work?

There is a step-by-step guide to the process of making toys. We have all the information you need about brainstorming, mass production, and more.

1. Make a plan

Once you have an idea and know the object you want to approach, you’re ready to design. We’ve put together a step-by-step guide to help you learn more about how toys are made.

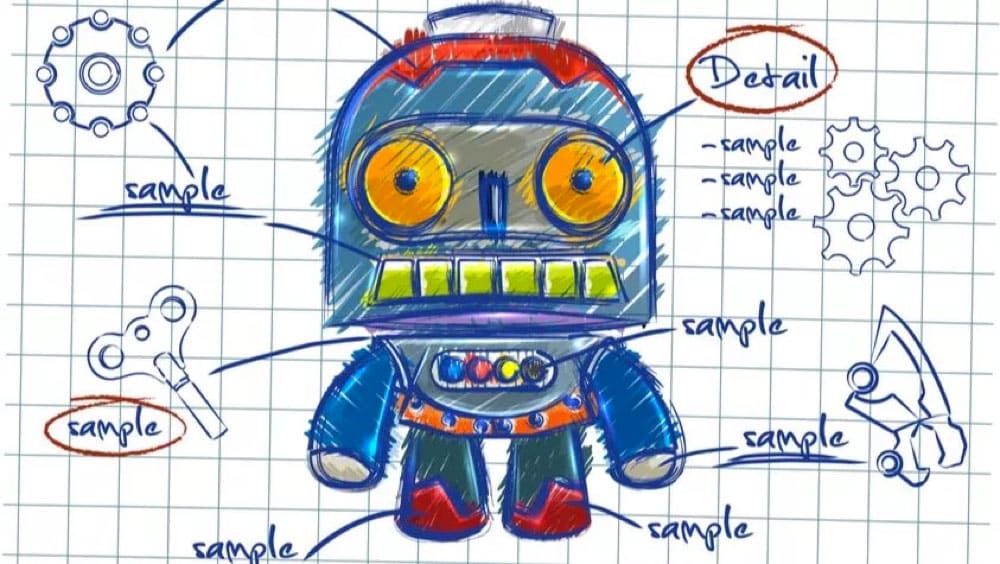

2. Think in detail

Brainstorming sessions will make your hard work come to life. Determine the final look of the toy and work on the intricate details. Creative thinking, fieldwork, and research are what you need.

Create a guiding vision through brainstorming sessions. You should always revisit your brainstorming sessions if unsure about a decision.

3. Make toy sketches

Ask a professional injection mold manufacturer for help or create your toy sketch. This design should include all the details discussed throughout the brainstorming session.

Size, color, and any differences should be considered during this session. When designing a plush animal or sculpture, try different expressions and styles in this toy-making process until you find one you like.

4. Make a 3D model

Once the drawing is complete, it’s time to turn it into a 3D model.

- Using software such as Zbrush, you can make realistic models of what your toy will look like when it’s finished.

- Hire a professional to do it for you. An experienced plastic mold maker will create a more polished, rendered model.

- Other options include hiring a wax modeler. A professional wax modeler can work faster than 3D software in most cases.

5. Create a prototype

During the toy manufacturing process, it is important to find out how to create a prototype.

You can use the prototype to sell your idea to the manufacturer. It is also a good indicator of how many resources you will need to mass produce the item.

Many basic elements come into play when making a prototype. Deciding how to make the toy, deciding on a manufacturing process for the plastic toy, producing a toy mold, and choosing materials.

You must first determine the number of molds needed to make the toy to determine how the toy will be produced.

This step requires the assistance of a mechanical engineer. Advanced knowledge of physics is required to determine the correct number of molds needed to manufacture the toy successfully.

6. Finding a manufacturer

Finding a suitable factory and a manufacturing company that operates that factory and is happy to accept your product can take some time.

Hiring a sourcing agent is a common means to help you determine your options, but you can approach the manufacturing company yourself if you wish.

You must find a transparent company that can source the materials you need to develop and provide the specialized skills and experience needed to nurture your product.

A standard toy manufacturer may not have the necessary utilities to nurture your approach. The important thing is to verify that they do at every level.

To make safe and long-lasting toys, your chosen factory must meet your specifications.

When selecting a factory, look carefully at the following list:

- Is the factory equipped with the molding components needed to produce the toy?

- If many molds are used, are there sufficient assembly lines?

- Does a strict quality control department supervise the process?

- Are the safety of the toys from the factory batch tested regularly?

- Do they meet your specific packaging needs?

Once the factory has provided appropriate answers to these questions, you should investigate the comments of other customers to verify the factory’s claims.

To maximize profits, quality control and safety measures must meet worldwide requirements so that toys can be launched in multiple countries.

7. Supply chain

The supply chain of your manufacturing process involves planning, sourcing, manufacturing, delivery, retailing, and consumption.

The manufacturing element of it involves demand forecasting (i.e., deciding how much quantity should be produced and making necessary adjustments based on market trends).

It identifies bottlenecks in your process and accounting analysis and optimizes your productivity through intelligent management.

Valuable manufacturing companies should be able to demonstrate to you why they are an asset to your supply chain and how they can fit comfortably into it.

This also means you must confidently assess each step of this journey to understand what you require from such a company. This can help you make decisions more easily.

For long-term success, pay as much attention to these factors as you do to the rest of the process:

- Marketing phase

- Delivering your product

8. Branding your product

Branding your company is key in establishing yourself as an operating entity, and most of the work should be done before manufacturing.

However, it is also true that products reflect as much on brands as brands reflect on their products, so it is important to ensure that the two are combined and synchronized.

A good place to start is to consider copywriting as a tool to introduce your audience to your conceptual design and unique presence.

Using imperative phrases and words that will appeal to your target audience and writing an ideal marketing brief to help you get your point across is crucial.

Graphic designs, such as those used on your packaging, can also add to the effectiveness of how you introduce yourself to this market.

All of these practices must be invested in and researched for maximum results.

9. Attracting buyers

Ultimately, you need to know who will likely buy your product and how to attract them. Even if your toy is designed for young kids, you won’t get a sale directly from them.

It’s their parents or caregivers who will make those purchase decisions. Therefore, all marketing materials must take this fact into account.

For example, many toy manufacturers do their best to market their products as hot toys in the run-up to Christmas, when spending levels have increased, and parents are more likely to research toys and their uses.

The most important qualities for parents are toys that prove to be educational (though not necessarily academic), long-lasting, safe, fun, and creative in some sense.

If you can meet these key markers, you have a better chance of success.

Toy Manufacturing Process Conclusion

Toys are made from various materials, including plastic, metal, and rubber. Follow all the factors when looking for a factory to make safe and durable toys for your kid or business.

Please leave the comments below if you have any questions or additional information about the toy manufacturing process.

I am Yan, the founder of Yansourcing, the best sourcing agent in China, who can quickly and safely help you buy and import from China. If you have any questions about importing from China, don’t hesitate to contact us.