Vertical integration is the process companies choose to pursue when they want to expand their business in multiple ways but still stay on the same production path. It can help companies reduce costs and increase efficiency through economies of scale.

Vertical integration also gives companies unparalleled reach, and if you have a company and are considering using it as a business strategy in your organization, it’s important to understand the advantages and disadvantages in advance.

What Is Vertical Integration?

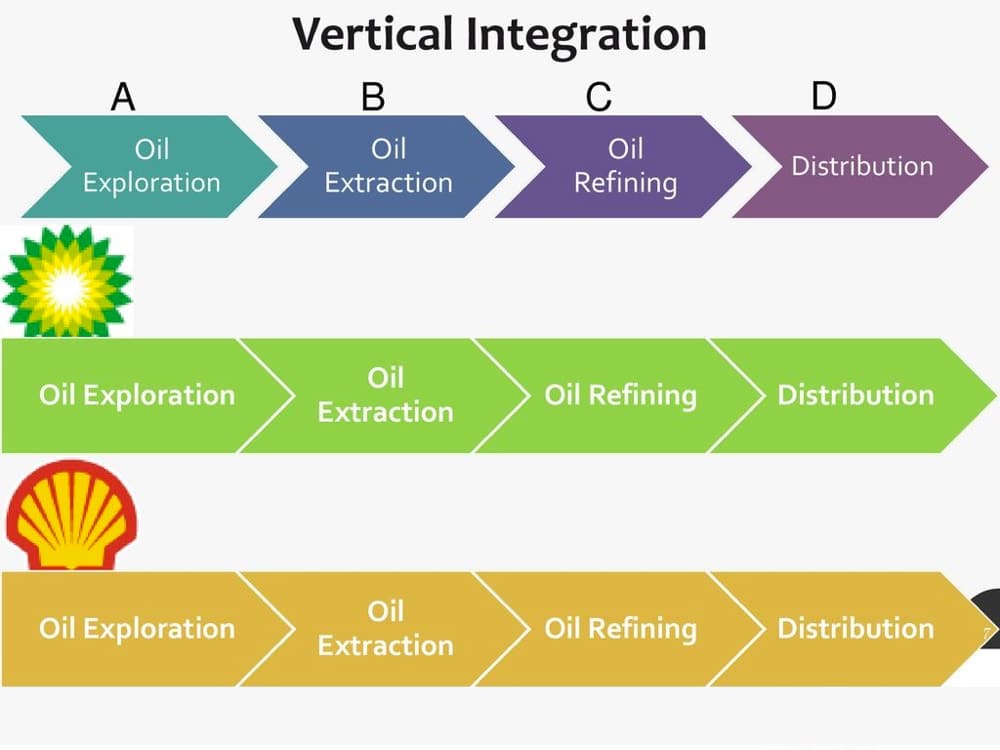

Vertical integration is a strategic structure in which a company is able to control multiple vertical levels of the supply chain.

It usually consists of one or two companies involved in different stages of production and encompasses all the steps from acquiring raw materials to transforming them into a product and selling that product.

In this sense, a vertically integrated company owns multiple (or all) parts of its supply chain.

For example, a company might acquire a cotton producer and a T-shirt manufacturing company, and then market and sell those products themselves.

Thus, the initial company (now a consortium of several companies in the same vertical or with similar products) now controls four parts of the supply chain: raw materials, manufacturing, distribution, and retail.

How Does Vertical Integration Work?

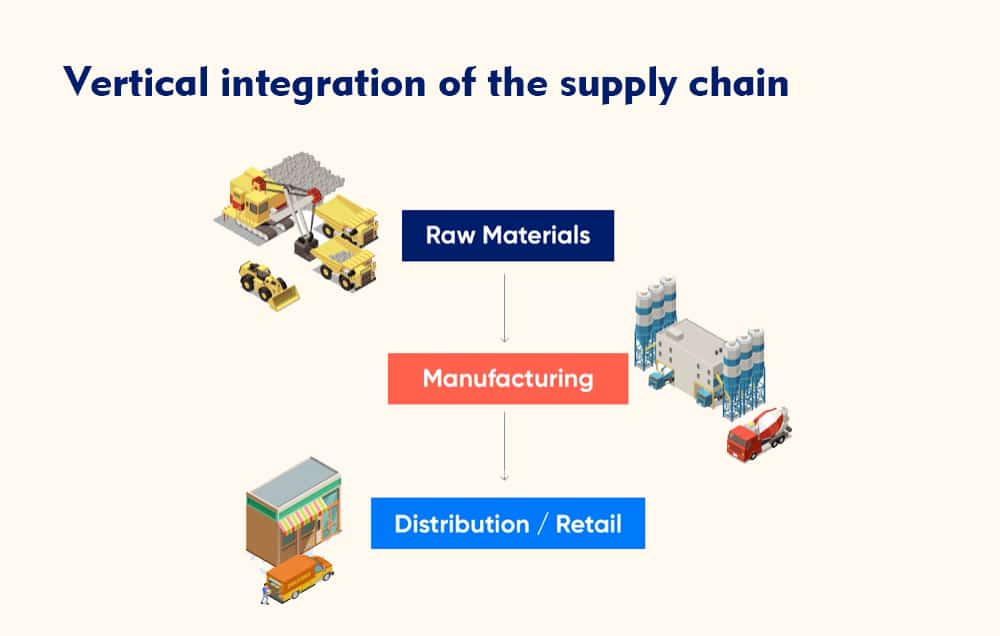

Here’s how vertical integration works in the supply chain:

At the back end of the supply chain, you have sourced raw materials. In the middle, your manufacturer transforms those raw materials into finished products.

At the front end of your supply chain, you have the distribution and retail outlets that deliver the product to the end consumer.

Let’s assume for a moment that each of these stages is handled by a separate company.

Each of these companies has its own end product or service that complements the other stages but does not compete with them directly.

Vertical integration occurs when a company at one stage of the supply chain acquires, merges, and partners with.

Or establishes another company at a different stage of the supply chain, thereby controlling two or more stages of product production or distribution.

Let’s use a hypothetical company to explain:

Bingo is a manufacturer of bulk ice cream and pre-packaged ice cream bars and pints. Bingo’s simplified supply chain looks like this.

Suppose Bingo decides to acquire a number of ice cream stores that sell its products.

In addition to owning and creating the product itself, Bingo now owns a series of branded retail stores. By having two levels of the supply chain, it is vertically integrated.

Or suppose Bingo decides to acquire its dairy supplier. Instead of a downstream acquisition, it acquires the upstream business.

But it still controls both stages of the supply chain, so it is still vertically integrated.

Vertical Integration Vs. Horizontal Integration: What Is the Difference?

As mentioned above, vertical integration is when a company merges with another company at a different stage of the supply chain.

So Bingo acquires its suppliers or retailers, not other manufacturers. This is where vertical integration differs from horizontal integration.

Horizontal integration involves the acquisition of competitors or closely related companies that operate at the same or similar stages of the supply chain.

Typically, they produce similar products, provide similar services, or operate in similar industries. Thus, suppose Bingo is considering horizontal integration.

Bingo’s competitors are other manufacturers – Connie’s Cones, Christian’s Creamery, and Don Cone-leone Gelato. In order to integrate horizontally, Bingo may acquire one or more other manufacturers.

This may be done to gain proprietary flavors, incorporate dietary and organic products into its portfolio, expand into new markets, eliminate competition, or all of the above.

What Are the Types of Vertical Integration?

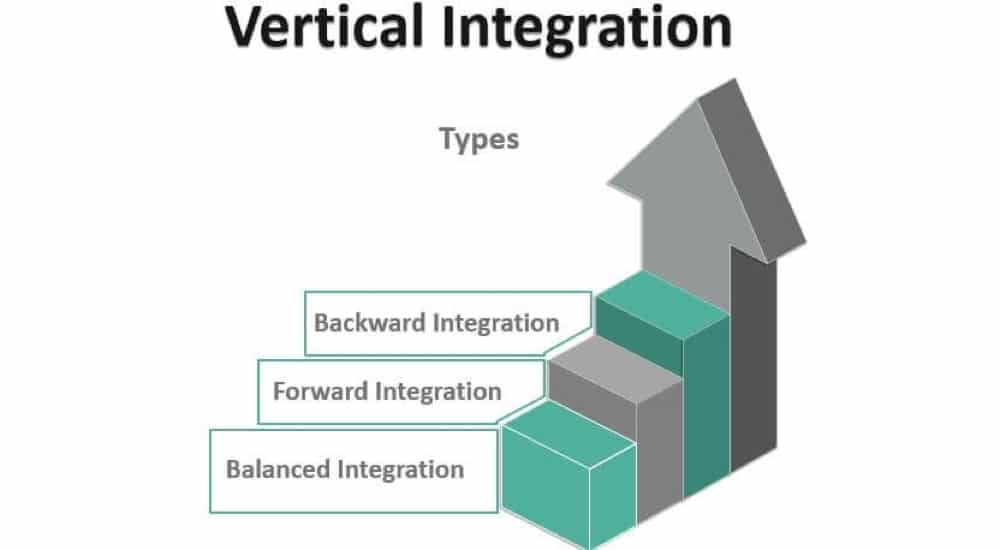

Let’s break down the 3 basic types of vertical integration. They are:

- Forward vertical integration

- Backward vertical integration

- Balanced vertical integration

What is forward vertical integration?

It is when a company is able to further control all stages of the supply chain. It is a state where a company regains ownership of its distributors and retailers.

It can be used when a company intends to focus on expanding its market share. Many manufacturing companies that use forward integration have online stores.

They sell their products directly to consumers, thus reducing the number of retailers.

What is backward vertical integration?

This happens when a manufacturing company operates at the end of the supply chain. It may start manufacturing intermediate products on its own and start supplying them.

In other words, backward integration simply takes over the previous ownership of suppliers.

A good example is when a movie distributor decides to produce content and distribute it at the same time.

Companies may want to integrate backward for the following reasons: to increase efficiency and to ensure a steady input of resources.

What is balanced vertical integration?

Balanced integration is a strategy that combines forward integration and backward integration.

This is implemented when both strategies prove difficult to implement and may end up costing the business money.

In this case, the strategies of both sides are combined to ensure the smooth and continuous operation of the business.

What Are the Advantages of Vertical Integration?

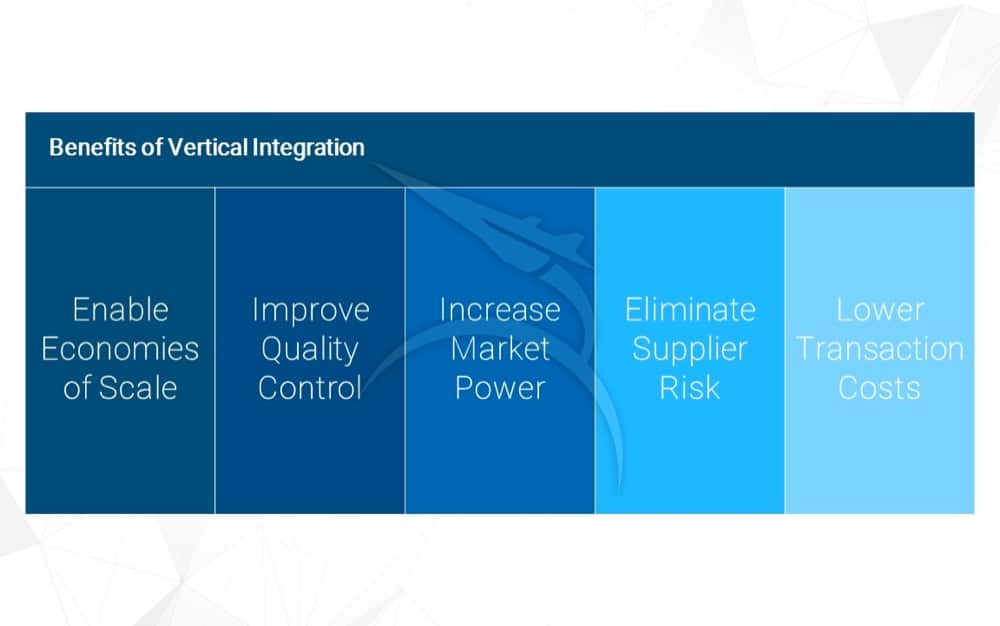

1. It allows companies to control multiple stages of the supply chain

Vertical integration occurs when a company can control multiple stages of its supply chain, which is the process organizations use to transform raw materials into usable products that consumers can buy.

Each basic supply chain has four stages: raw materials, manufacturing, and production, distribution, and retail. Efforts in this area allow companies to control two or more of these areas.

2. It increases the product knowledge and marketability of the brand

One of the less obvious benefits of a successful vertical integration attempt is knowing the market and what is known about the product.

When there are non-pain points that must be addressed, producing products that correct the errors of previous attempts will provide additional value to consumers.

This process allows vertically integrated organizations to meet their market needs with greater consistency, whether they decide to sell a product they manufacture or one that represents a product from a strategic partnership.

3. Companies no longer need to rely on suppliers

Many organizations see vertical integration as a way to create independence in their supply chains.

When this effort is successful, companies no longer need to rely on their suppliers to bring their products or services to market.

This means less risk is taken if their partnerships become disruptive due to a lack of management skills.

This advantage can also make it easier to avoid labor disputes and frequent employee strikes when companies operate in mixed economies that are closer to socialism than to capitalism.

4. Vertical integration can open up new markets for the organization

The process of vertical integration allows organizations to open up new markets for themselves. This advantage is possible regardless of whether the effort is forward or backward.

As companies begin to develop new assets, including intellectual property, technology improvements, real estate acquisitions, and other projects that improve access to consumers, the reduction in barriers creates more opportunities to close deals.

This not only reduces the cost per deal but also increases the number of lots traded. When there are fewer lots in the cookie jar that require a certain percentage of profit, more money flows to the organization.

5. It allows the organization to dictate the terms of the relationship

Sometimes vertical integration is necessary because suppliers in the market have enough power to dictate to the company.

This problem often occurs when one of the suppliers has a monopoly in the area in which the organization in question is doing business.

By vertically integrating the supply chain, it is possible to bypass the suppliers that control most of the market and gain the benefit of being able to offer a better pricing structure because there is more control over internal costs.

6. Vertical integration helps increase a company’s market share

Companies that invest in vertically integrated processes will control more of the supply chain.

This effort provides companies with more advantages over their “perfect customers” who may want to address unique pain points.

Because the messages shared with each consumer come from internal sources, it is easier to identify specific market segments that the organization can dominate.

When vertical integration investments occur, the comparison factor between brands increases. If a product or service becomes better because of this effort, it is more likely to gain sales.

7. Vertical integration creates more information available for review

From a data collection perspective, the process of vertical integration creates more predictability for the organization.

This advantage is possible because the company has access to more information due to the increased availability of production inputs.

Retail channels can create real-time data that does not go through a third-party filtering process.

Distribution requirements in vertical integration can be adjusted to promote personalized products to specific populations.

With more control from start to finish, companies can quickly adapt to changes to achieve the most effective results.

8. It reduces the organization’s transaction costs

Companies that are able to complete the vertical integration journey will have more control over their supply chain from start to finish.

This means they can use this leverage to start reducing transaction costs throughout the journey.

Suppliers and vendors can leverage the size and scope of the organization to create a positive impact on their own efforts while reducing costs for the organizations involved.

This advantage is why Walmart is often successful in offering lower prices than its in-store buying competitors.

With thousands of stores and millions of customers, they are one of the largest companies in the world.

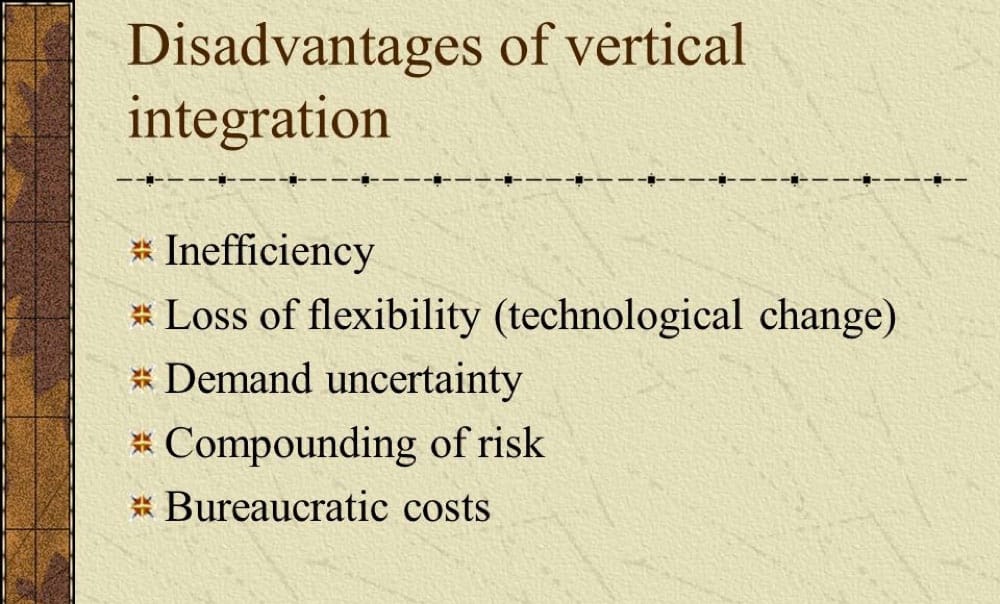

What Are the Disadvantages of Vertical Integration?

1. There may be a capacity balance problem

A good example of this situation is when a company needs to build excess upstream capacity to ensure that its downstream business is adequately supplied under any demand conditions.

This may even lead to retaliation against the business’s previous suppliers, which may jeopardize its primary production.

2. High capital requirements for vertical integration

The company must have a significant amount of capital available to invest in vertical integration processes.

Efforts to move forward and backward are often costly, even when the emphasis is on building partnerships rather than full ownership.

Transactions in this area often include proprietary data, specific patents, and research processes that may require significant assets.

After beginning this effort, organizations often find they need more staff, better training facilities, and more real estate.

3. It creates more difficulties

Note that the economies of scale of vertical mergers will be reduced because most of their production processes are at different levels. Moreover, there is room for monopoly rights or even monopoly rights.

For example, bundled bars can charge consumers higher prices for a smaller selection of beer.

4. Loss of specialization due to vertical integration

Although it is sometimes difficult to identify this disadvantage, the danger of vertical integration is that each production stage requires a different management approach.

Manufacturers and processors have different needs than wholesalers or retailers.

For example, oil companies in the 1930s thought it was a good idea to own gas stations, but demand varied so much that they phased out ownership in favor of franchising.

5. The organization must operate in a larger economy

If companies believe that vertical integration is necessary for their future, they must force themselves into a growth period.

Many advantages are possible when the organization can use its size as leverage. But before it can make this attempt, it needs to get there in a stable financial position.

When an organization tries to expand too quickly, the instability of its financial position can have devastating consequences.

6. Vertical integration reduces a company’s flexibility

When an organization works with several different contractors and suppliers, the end result can be greater flexibility than when everything is internalized.

When working forward or backward, the supply chain sees fewer options rather than more, which means adapting to rapidly changing economic conditions can be challenging.

When companies use third-party providers, they have the option to make changes under contract without any infrastructure maintenance costs.

7. Some barriers to market access

Manufacturing companies that can control access to key raw materials and components due to vertical integration often create some barriers to market entry.

They have the ability to limit competition and will establish a strong position in the market to protect their customer base.

However, they may face antitrust regulators who believe they are influencing market concentration.

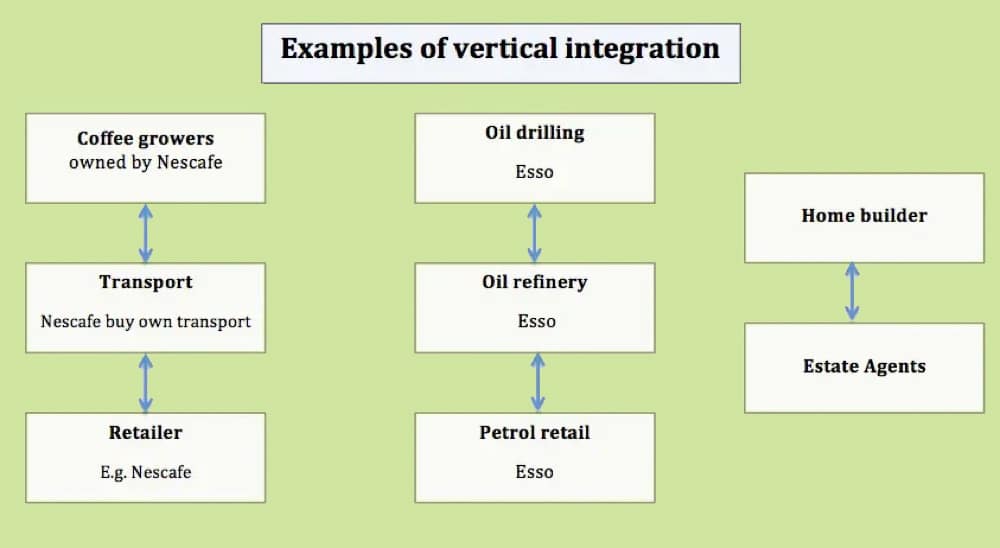

Examples of Vertical Integration

Amazon

Amazon has vertically integrated much of its business.

Not only does it act as a marketplace for buyers and sellers, but it also offers its own products and services, as well as its own distribution channels.

So in effect, it has 3 stages in its supply chain. It sources, markets, and sells products on its website, and then distributes them.

Carnegie Steel

Carnegie was a large steel manufacturer in the late 19th century. It was vertically integrated by acquiring companies ahead of itself in the supply chain.

The steelmaking process required the extraction of raw materials, iron ore, and coal. It then needed to refine these materials before sending them to Carnegie Steel to be manufactured into the final product.

Carnegie Steel owns both the miners that extract the raw materials and the refineries, thus owning almost the entire supply chain.

IKEA

Known as a flat-pack retailer, IKEA sells mainly wooden furniture, but also other fixtures and accessories. It is the last in the supply chain, as it sells directly to the final consumer.

In 2015, IKEA took a big step forward in ensuring full vertical integration by purchasing Forest of Romania.

The company added to this by purchasing forest land in Alabama in 2018, allowing the company to aim for a sustainable supply chain.

Not only does it now control much of the raw material production, but it also controls the manufacturing process through its subsidiary Swedwood, which was renamed IKEA Industries in 2013.

It thus controls the production, manufacturing process, and final distribution of wood through its retail units.

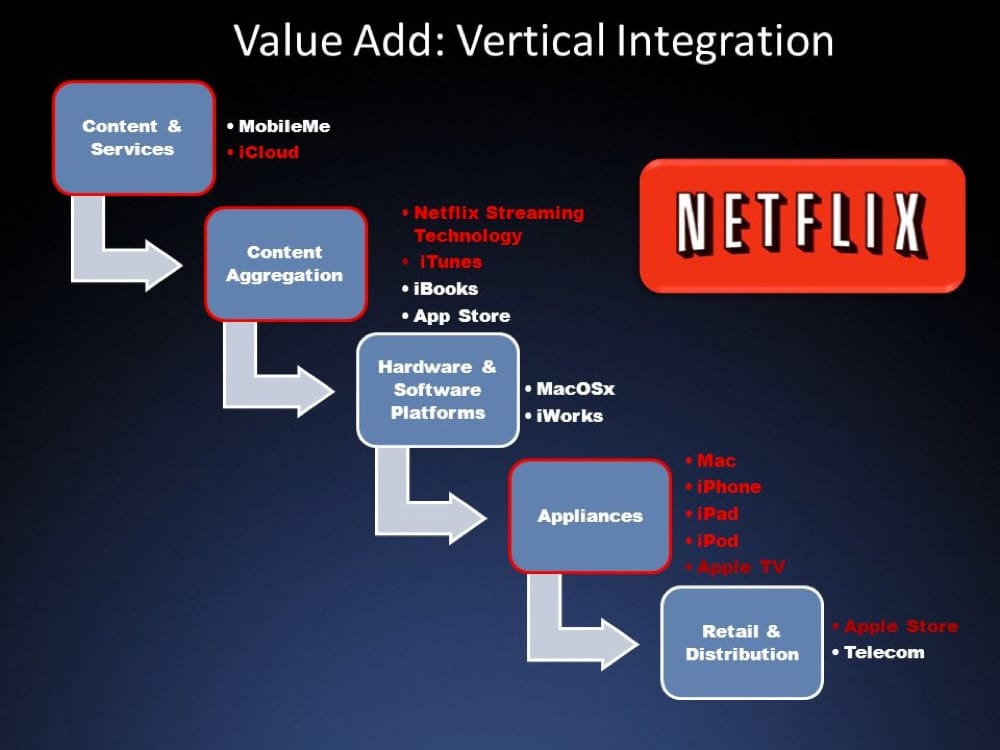

Netflix

Netflix is known as a streaming media service provider, the end of the supply chain, interacting directly with consumers. It provides a platform for the production of movies, television, and other content.

However, the company relies on third parties to deliver the new content its subscribers want. At the same time, it had to pay a premium, especially for large shows.

In 2013, Netflix decided to vertically integrate and enter the production business. As a result, it not only produced shows and movies but also offered a distribution network through its streaming service.

This strategy became crucial, as it helped differentiate it from its competitors and control the types of shows available.

Zara

Zara is a Spanish clothing and accessories company with over a thousand stores worldwide.

Not only does it have its own retail stores and distribution channels, but the vast majority of its clothing is sourced in-house.

Zara is vertically integrated with the manufacturers and designs of its merchandise. While other stores rely on independent designers and manufacturers, they are at their mercy.

By contrast, Zara is able to adapt to new trends faster than its competitors. It has also improved the efficiency of inventory management, which is crucial in fashion design.

Vertical Integration FAQ

1. What is the difference between vertical and horizontal integration?

In horizontal integration, a company expands its customer base and product offerings, usually by purchasing competitors or other complementary brands.

It aims to increase profitability through economies of scale rather than by expanding operational control as in vertical integration.

2. Who created vertical integration?

The concept of vertical integration has been around since the Industrial Revolution. Andrew Carnegie was one of the first to use it extensively.

His company, Carnegie Steel, controlled the iron ore mines used to extract steel resources, the coal mines that fueled the steel, the railroads that transported the materials, and the steel mills themselves.

3. What is an example of vertical integration?

Vertical integration is the joining together of two companies at different stages of the supply chain. One example is Netflix, which started out as a platform for content producers.

Since its inception, it has been vertically integrated so that it not only distributes final content but also produces it through “Netflix Originals”.

Vertical Integration Conclusion

The advantages and disadvantages of vertical integration suggest that it can be a useful investment if sufficient funds are available to do so.

To take full advantage of the benefits that vertical integration can provide, challenges must be addressed.

For those who can meet these challenges, the potential for long-term benefits in markets of any size is far-reaching.

We are Yansourcing, a leading sourcing company in China, dedicated to helping our clients source products from China at the most competitive prices. If you are interested in importing from China, please contact us.