If you sell tiles for a living—distributor, wholesaler, or e-commerce category owner—you don’t win on pretty samples alone.

You win when your container shows up and every carton matches in shade, caliber, and finish, with breakage and returns kept to a minimum.

This guide shows exactly how to spec, audit, test, pack, and ship ceramic and porcelain tiles from China so your inventory is consistent and your landed cost stays predictable.

Ceramic vs. porcelain: the classification and why it matters

In the U.S., porcelain is defined by water absorption of 0.5% or less, determined by ASTM C373. ANSI A137.1 uses that C373 test to classify tile types, and the Porcelain Tile Certification Agency follows the same threshold. See the overview in ASTM’s “Standards and the Ceramic Tile Industry” (2024), which explains how C373 underpins classification in practice: the ≤0.5% rule is the line for porcelain.

Slip resistance for level interior spaces walked on when wet is commonly represented in the U.S. with DCOF testing. ANSI A326.3 provides the test method and interpretations; many buyers target a minimum DCOF of 0.42 for those interior wet areas based on ANSI/TCNA guidance. For broader context and related standards, see the TCNA standards and resources hub.

In the EU/UK, EN 14411 governs classification, characteristics, and marking. Fully vitrified porcelain corresponds to Group BIa with water absorption ≤0.5%. Slip resistance is covered under EN 16165 methods, while adhesives are defined in EN 12004. A good starting point is the EN 14411 classification entry (CEN/ISO catalog).

Bottom line: specify the classification by standard and insist on recent test reports that match your target market’s framework (ANSI/ASTM for U.S.; EN for EU/UK). That way, your claims and product pages stand on verifiable documents, not assumptions.

What to put in your RFQ/spec so factories quote apples-to-apples

A precise RFQ avoids vague replies and patchy samples. Ask for current test reports and define how you’ll control shade and caliber. Use the table below as a starting point for your RFQ/spec.

| Field | What to request | Why it matters |

|---|---|---|

| Base and absorption | Declare substrate/type and water absorption %. If porcelain, require ≤0.5% with recent ASTM C373 (U.S.) or EN 14411 BIa evidence (EU/UK). | Confirms classification and suitability for wet/exterior conditions. |

| Intended use & slip exposure | For interior wet floors, request DCOF test per ANSI A326.3 with target ≥0.42; for ramps/exteriors, cite local code or EN 16165 method. | Matches product to real-world safety expectations. |

| Abrasion class | Specify PEI (I–V) for glazed tiles or EN abrasion class; map to traffic profile (e.g., PEI IV/V for heavy commercial). | Reduces premature wear and returns. |

| Dimensions & tolerances | State nominal and actual size; rectified or pressed; caliber code; thickness tolerance; face warpage/flatness; squareness. | Predicts grout joint size and installation quality. |

| Shade control | Define shade/tone number; require same batch across zones; retained master samples; photo logs under neutral lighting. | Prevents visible patchwork across large areas. |

| Mechanical/surface properties | Breaking strength (ASTM C648), modulus of rupture, chemical/stain resistance. | Guards against chipping and staining complaints. |

| Finish & surface | Matte/polished/textured; inkjet design; edge type; lappato/anti-slip treatments. | Aligns look/feel with customer expectations. |

| Packaging & tests | Carton contents (pcs/sq ft/kg); pallet pattern; corner protection; moisture barrier; drop-test method requested. | Minimizes breakage in handling and transit. |

| Labels & traceability | SKU, shade, caliber, batch, production date; barcode for e-commerce. | Makes warehouse allocation and reorders reliable. |

| Documents & compliance | C373, A326.3/EN 16165, abrasion class; DoP/CE (EU); origin docs; HTS code; exporter’s AD/CVD duty rate (if applicable). | Keeps customs and listing pages clean and accurate. |

Tip: include acceptable variances (e.g., maximum warpage, thickness tolerance, delta E if your lab supports it) right in the PO. If it’s not on paper, it’s hard to enforce.

Shortlist the right factories: audit criteria that predict stable shade and caliber

You’re looking for kilns and finishing lines that can repeat a design week after week. During qualification, verify:

- Equipment and maintenance: kiln capacity and stability, number/type of inkjet printers, glazing lines, and rectification equipment; calibration/maintenance records on file. A rectification line out of tune is the fastest path to off-caliber “rectified” tiles.

- In-house test capability: basic lab for water absorption (C373 equivalent), breaking strength, and surface tests. If missing, name a third-party lab and cadence for periodic tests; directories and publications on the TCNA site can help you locate resources.

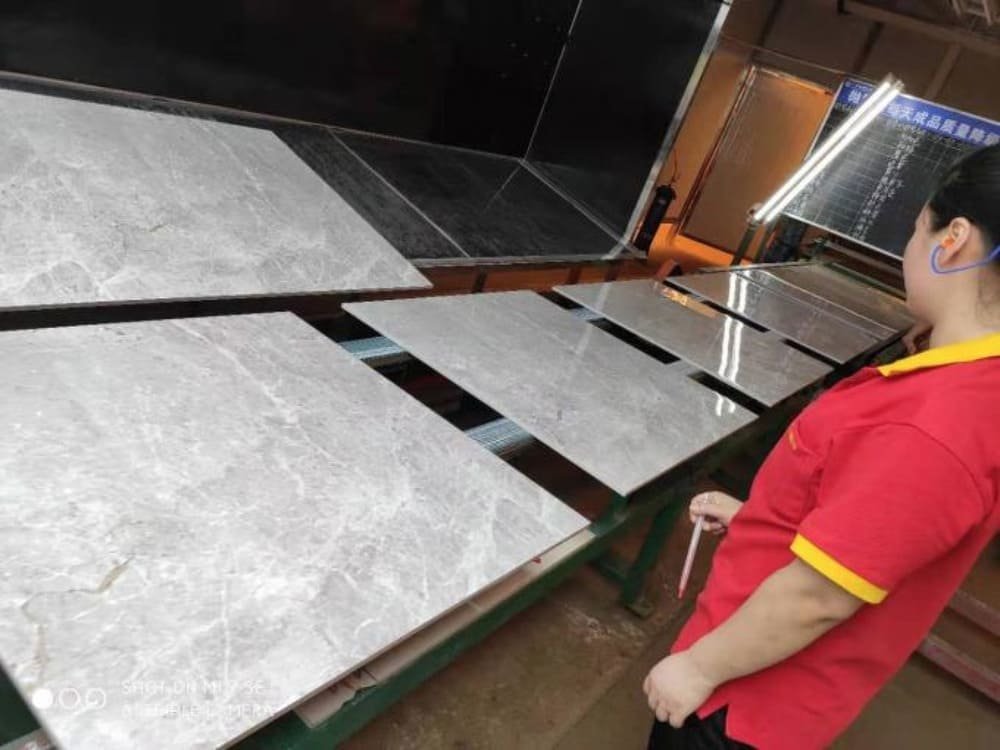

- Shade control SOP: lot/batch coding rules, shade and caliber codes printed on every carton, controlled-light inspection booths, and master sample retention for at least one year.

- Export track record: prior shipments to your target market, with references and product lines similar to your specs.

Ask to see production travelers or batch records that tie shade and caliber codes to specific dates/lines. If a factory can’t trace a carton back to a batch, it’s not ready for project-critical orders.

QC in the real world: from first-article to pre-shipment

Set three gates for quality: first-article approval, in-process checks, and pre-shipment inspection.

First-article approval

- Approve against your retained master sample.

- Inspect color under neutral light, confirm texture/finish, and measure face size and thickness.

- For rectified edges, check edge micro-chips and squareness.

In-process checks

- Define measurement intervals for caliber and warpage; require photo logs next to the master sample with date and line ID.

- Spot-check DCOF or abrasion documents if the line changes glaze or surface treatment mid-run.

Pre-shipment inspection (PSI)

- Use ANSI/ASQ Z1.4 sampling for cartons and pieces.

- Categorize defects as critical (cracks), major (edge chips, glaze pinholes, off-caliber), and minor (tiny specks), with AQLs written in your QC checklist (e.g., 0 for critical, 1.0–2.5 for major, 4.0 for minor).

- Verify carton labeling and shade/caliber consistency.

- Supervise container loading or request a loading report with photos.

For property thresholds and test context, see a concise technical summary that compiles ANSI A137.1 property minima such as breaking strength testing per ASTM C648: Ceramic & Porcelain Tile Testing overview (2024)

Document retention isn’t busywork. When a dispute happens months later, those photos against the master sample and the PSI sampling sheet become your defense.

Packaging, palletization, and loading plans that cut breakage risk

Tiles are dense and brittle. The way you box, stack, and brace them determines how much arrives in one piece.

Cartons and internal protection

Use heavy-duty cartons sized to limit free play. Add separators (cardboard/honeycomb), foam sheets for polished surfaces, and corner protectors. Keep SKUs consistent per carton to simplify claims and receiving.

Palletization

Use ISPM-15 compliant pallets. Align cartons flush with the pallet edge—overhang invites corner damage. Strap and stretch-wrap tightly with corner guards. Respect stack-height limits based on carton compression specs.

Large formats and panels

For 600×1200 mm and larger, consider crating or A-frames with padding to stop flexing. Keep loads vertical and supported; panels hate bending moments.

Container loading

Favor FCL to reduce handling touchpoints. Distribute weight evenly, eliminate voids with dunnage/airbags, and brace near doors. Build a load-plan map so your warehouse team can check counts and placement on arrival.

For a logistics overview from a tile industry perspective, see this tile import logistics explainer.

Insurance and claims

Buy all-risk cargo insurance that explicitly covers breakage and moisture. Photograph packing and loading. On arrival, inspect before the cargo fully disperses; note exceptions immediately for the surveyor and insurer.

Compliance and landed cost: standards, documents, and trade remedies

Standards and documents

- U.S.: Classify and market products using ANSI/ASTM references (e.g., A137.1, A326.3) and installation standards (A108/A118/A136.1). The TCNA standards hub is the primary publisher for industry references and handbooks.

- EU/UK: Use EN 14411 (classification/marking), EN 16165 (slip), and EN 12004 (adhesives) for documentation and product pages; consult the EN 14411 catalog page for scope.

HTS and trade remedies

- U.S.: Tiles generally fall under HTSUS Chapter 69 (e.g., 6907/6908). Use the USITC HTS tool to verify current codes: HTSUS Chapter 69 at USITC. Anti-dumping (AD) and countervailing (CVD) orders remain in place for ceramic tile from China; check current Federal Register notices and confirm exporter-specific rates with your customs broker.

- EU: Anti-dumping duties on Chinese ceramic wall/floor tiles were renewed for five years to 2029; exporter rates vary. See this industry summary of the regulation: Implementing Regulation (EU) 2024/493 renewal overview.

- UK: The UK maintained AD duties on many Chinese tiles while adjusting scope for formats not produced domestically. See the tile industry update summarizing 2024 actions: UK anti-dumping duty update for Chinese tile imports (2024).

Practical takeaway: Treat AD/CVD as exporter-specific. Before you issue a PO, confirm the exact producer/exporter combination’s rate and bake it into your landed-cost model.

A practical, step-by-step sourcing workflow you can run this quarter

1. Scope and RFQ

Define formats, finishes, and performance requirements. Build your RFQ/spec with the table above, list acceptable variances, and require current test reports (C373, A326.3/EN 16165, abrasion class).

If you need a head start, this building-materials service overview can help you structure specs and QC: Design-to-China Building Materials Sourcing Package.

2. Factory shortlist and audit

Target kilns with rectification capability and consistent inkjet lines. Audit equipment, maintenance logs, shade/caliber SOP, and traceability. Confirm export references for similar SKUs.

3. Samples and lab tests

Approve aesthetic samples against your concept board. For performance, request or commission lab reports aligned with your market’s standards framework.

4. Pilot run and first-article

Run a small batch. Approve the first article against your master sample and dimensional tolerances. Lock shade and caliber codes for the production order.

5. Production monitoring

Set in-process checks for dimensions and warpage; require photo logs and batch records. Keep a communication cadence with the line supervisor.

6. Pre-shipment inspection and loading supervision

Apply AQL sampling for cartons/pieces; verify labeling (shade, caliber, batch, date). Supervise or document container loading.

For broader project consolidation or hospitality orders with many SKUs, see how mixed-SKU plans are handled in China sourcing for hotel projects.

7. Logistics, insurance, and customs

Choose FCL where possible, insure for breakage/moisture, and validate HTS and any AD/CVD exposure before sailing. Prepare your receiving team with the load-plan map.

8. Arrival inspection and release

Inspect early, photograph exceptions, and file claims quickly. Store retained samples and batch documentation so reorders match.

If your company focuses broadly on construction and interior products, our category hub outlines how sourcing and QC flow for building materials: Building Material sourcing.

Next steps

If you want a ready-to-run process with audited factories and on-site QC focused on shade, caliber, and defect control, Yansourcing can help.

- Request a sourcing quote and get the Tile Sourcing RFQ Pack (spec sheet, QC checklist, container load list).

- We’ll align your RFQ with ANSI/ASTM or EN frameworks, shortlist capable kilns, and set up inspection gates so your cartons land consistent—batch after batch.

Questions about a live project?

Send your formats, finishes, square footage, and required standards, and we’ll advise on feasibility, timelines, and landed cost assumptions before you commit.