Understanding manufacturing businesses is important to keep up today. In 1979, about 20 million Americans worked in factories. By 2020, 80% of jobs were in services instead. This change shows how industries grow and why learning helps you stay ahead.

Looking at types and strategies in manufacturing can save money. It also helps improve how things are made and boosts results. Manufacturing isn’t only about making stuff; it’s about matching work to customer needs. When you do this well, you set yourself up to succeed for a long time.

Key Takeaways

Learn about types of manufacturing: discrete, process, job shop, batch, continuous, and additive. Pick the one that works best for your business.

Use technology and machines to work faster. Start small by automating easy tasks to save time and money.

Make sure products are high quality to keep customers happy. Check for mistakes often to fix problems early and save money.

Think about eco-friendly manufacturing. Being green can lower costs and attract customers who care about the planet.

Look at global markets to grow your business. Study new areas for chances to expand and work with local experts to solve problems.

Types of Manufacturing Businesses

Manufacturing isn’t the same for every business. Companies use different ways to make things based on their products. Here are three common types of manufacturing businesses to help you decide which fits your needs.

Discrete Manufacturing

Think about cars, phones, or chairs. These come from discrete manufacturing. This type makes separate items you can count, like screws or parts. The pieces are put together to create the final product.

Discrete manufacturing is flexible. You can make one item or thousands. It’s great for businesses that need custom products or different order sizes. If your customers want unique solutions, this might work for you.

Process Manufacturing

Now, think of soda, paint, or medicine. These are made using process manufacturing. Instead of putting parts together, raw materials are mixed and changed. Once made, you can’t separate them back into the original materials.

Process manufacturing is best for industries using recipes or formulas. If your business works with liquids, powders, or gases, this method ensures products are consistent and efficient.

Job Shop Manufacturing

Job shop manufacturing is like a custom workshop. It focuses on making small, unique batches for specific customers. For example, a shop making special tools or custom jewelry. Each job needs its own setup and process.

This type is ideal for businesses making high-quality, custom items. If your customers care about detail and personalization, a job shop setup could be perfect for you.

Batch Manufacturing

Batch manufacturing means making products in groups or sets. Think of baking cookies. You mix, bake one batch, then repeat. Factories use this same idea. They make a set amount, then move to the next group.

This way is great for being flexible. You can switch products without big changes. For example, a shampoo maker can do one scent today and another tomorrow. Batch manufacturing helps meet customer needs while saving materials.

Tip: If your business makes seasonal or limited items, batch manufacturing works well.

Continuous Manufacturing

Continuous manufacturing is like a nonstop factory line. Products are made all the time, with materials added constantly. Think of oil refineries or paper factories. These businesses use continuous manufacturing to meet big demands.

This method is best for making large amounts of the same product. It’s fast and avoids delays. But it’s not good for items needing frequent design changes.

If you need to make many products quickly, continuous manufacturing saves time and money. It’s perfect for industries focused on speed and quantity.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is a new way to create. Instead of cutting or shaping, it builds items layer by layer. It’s like stacking blocks to make something cool.

This method is great for testing ideas or making custom designs. You can create special shapes and try new things fast. Additive manufacturing is used in healthcare, airplanes, and fashion.

Note: If you want to be creative or make unique items, 3D printing helps you stand out.

Strategies for Manufacturing Success

Success in manufacturing businesses takes planning and smart choices. You need strategies to work faster, save money, and make great products. Here are three ways to help your business succeed.

Technology Adoption and Automation

Technology is changing how factories work. Using new tools and machines can make your work easier. For example, Manufacturing Execution Systems (MES) help track production and resources. They also show how well things are running. This helps you avoid delays and make better decisions.

Here’s how technology helps manufacturing:

Key Component | How It Helps |

|---|---|

Manufacturing Execution Systems | Supports digital upgrades |

Real-time production monitoring | Makes work faster |

Quality management | Improves product standards |

Resource tracking | Uses materials wisely |

Performance analysis | Boosts productivity |

Digital transformation initiatives | Cuts maintenance costs and improves equipment |

Automation is also important. Companies like Ansaldo Energia use real-time data to improve their factories. Machines that talk to each other help with quality and repairs. This shows how technology can make work smoother and cheaper.

Tip: Start small by automating simple tasks. Add more systems as you grow.

Cost Reduction and Efficiency Optimization

Saving money is key in manufacturing. Cutting costs and working smarter helps you compete. Lean operations focus on removing waste and improving processes. This lets you do more with fewer resources.

Here’s how cost-saving strategies work:

Benchmark Type | What It Does | How It Helps |

|---|---|---|

Cost Efficiency | Lowers expenses while keeping good results. | Saves money. |

Lean Operations | Removes waste and simplifies work. | Cuts extra costs. |

Predictive Maintenance | Uses AI to stop breakdowns early. | |

Business Optimization | Smarter planning saves money. | Cuts operational costs by 30%. |

Using predictive maintenance avoids surprise repairs and saves time. Better workflows can lower costs by up to 30%. These ideas save money and make your work better.

Note: Check your processes often to find ways to save without losing quality.

Quality Control and Assurance

Good quality is very important in manufacturing. It keeps customers happy and stops problems early. Strong quality checks save time and money by catching mistakes before they grow.

Here’s how quality assurance helps:

Quality Metric | Benefit |

|---|---|

Cost Savings | Stops waste and saves money. |

Production Efficiency | Keeps products consistent and reliable. |

Continuous Improvement | Helps adapt to new challenges. |

For example, regular inspections find problems early. This reduces waste and keeps standards high. Training workers also lowers mistakes and improves results.

Callout: Quality builds trust. Happy customers will return for more.

By using these strategies, you can make your factory better, save money, and create excellent products. Whether it’s using new tools, working smarter, or focusing on quality, these steps will help your business grow.

Lean Manufacturing Principles

Lean manufacturing means doing more while using less. It focuses on reducing waste, working smarter, and giving customers value. By using lean ideas, you can improve production and save resources without lowering quality.

Here are some key ways lean manufacturing helps businesses:

What It Shows | |

|---|---|

Equipment Effectiveness | Checks how well machines work and finds ways to improve. |

Cost per Unit | Tracks the cost to make each item, helping spot waste. |

Capacity Utilization | Shows how much of your factory’s ability is being used. |

Carbon Footprint | Measures how your work affects the environment, supporting green practices. |

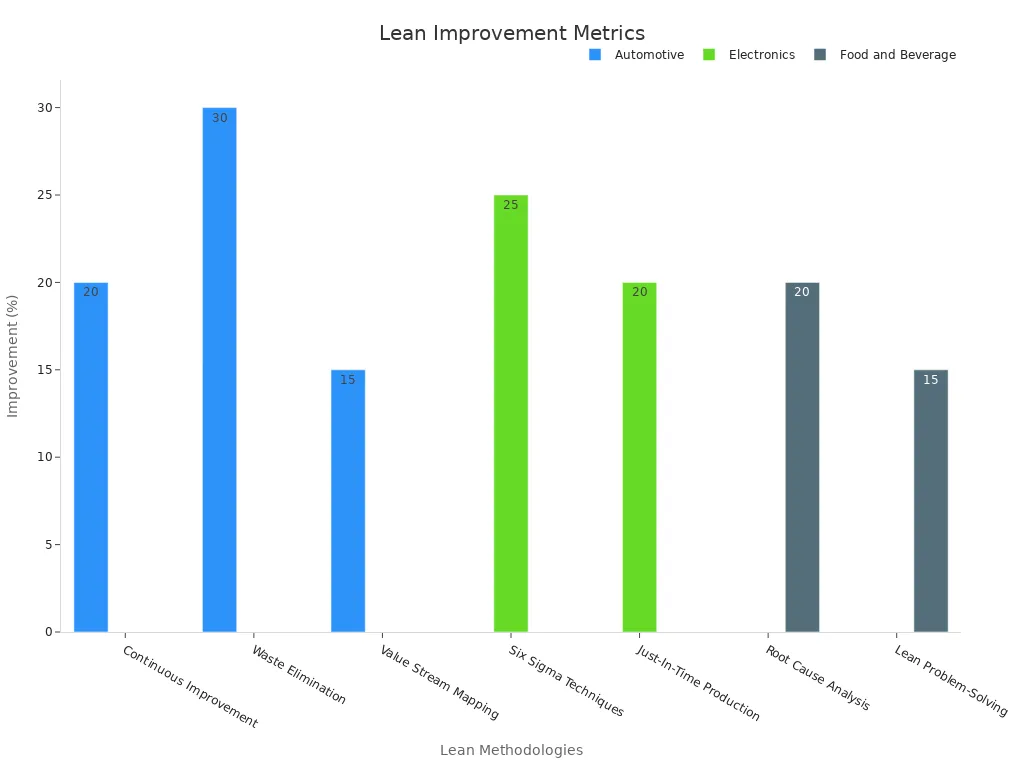

Lean methods work in many industries. For example, car makers cut downtime by 30% by removing waste. In electronics, Six Sigma lowered defects by 25%. These changes show how lean ideas can improve your business.

Tip: Start small. Pick one part of your process to fix waste and improve. Slowly add lean ideas to other areas.

Lean manufacturing isn’t just about saving money. It’s about building a system that adjusts to change and keeps making great products. By always improving, you can stay ahead in a fast-changing world.

Innovation and Product Development

Innovation helps manufacturing businesses grow and succeed. It’s how you solve problems, stay ahead, and make products customers enjoy. But how can you add innovation to your process? Let’s explore.

Why Innovation Matters

Innovation isn’t just about better products—it changes how they’re made. This could mean using new materials, trying advanced tools, or changing your production steps. The result? Faster delivery, improved items, and happy customers.

Here’s how innovation helps manufacturing:

Metric | What It Shows |

|---|---|

Tracks how much money your company makes. | |

New-product sales as a percentage of total sales | Shows how new items help your earnings. |

R&D spend as a percentage of total sales | Measures how much you spend on research. |

Time to market (TTM) | Tracks how fast you launch new products. |

Idea generation rate | Counts how many new ideas your team creates. |

Idea kill rate | Tracks the ideas that don’t move forward. |

Product kill rate | Measures how many products are stopped during development. |

Financial metrics | Checks the return on your innovation spending. |

These metrics show where you’re doing well and where to improve.

How to Foster Innovation

You don’t need a big budget to innovate. Start by encouraging your team to think creatively. Give them time to brainstorm and test ideas. Use tools like 3D printing to make prototypes quickly and cheaply. This saves time and lets you try new things without big risks.

Here are ways to boost innovation:

Focus on new products-to-margin conversion. This ensures new ideas help profits.

Check the risk of innovation projects with a weighted average risk score.

Set aside time for your team to work on innovation.

Tip: Watch your time-to-market. Launching faster helps meet customer needs sooner.

Making innovation a priority improves products and strengthens your market position.

Leveraging Yansourcing for Building Materials

Finding the right partner for building materials is important. Yansourcing makes this easy. With over 10 years of experience, they save you time and money while ensuring quality.

Why Choose Yansourcing?

Yansourcing helps find top-quality materials like furniture, lighting, and bathroom fixtures. Whether you need standard items or custom designs, they can assist. Their trusted supplier network offers great materials at good prices.

Here’s why Yansourcing stands out:

Customization Options: Need something special? They create products to match your needs.

Quality Control: Every item is checked carefully to meet your standards.

Logistics Support: They handle storage and shipping, so you can focus on your work.

How Yansourcing Supports Your Growth

Imagine you want to expand your product line but lack time to find suppliers. Yansourcing connects you with the right partners for smooth production and on-time delivery.

For example, if you need marble or cabinets, Yansourcing ensures they meet your design and durability needs. They also offer packaging solutions to improve your brand’s look.

Callout: Yansourcing isn’t just a sourcing agent—it’s your partner for success. Their knowledge makes global sourcing simple and effective.

Using Yansourcing helps you simplify your supply chain, cut costs, and focus on making great products.

Growth Opportunities in Manufacturing Businesses

The manufacturing industry is changing quickly. To stay competitive, you need to find new ways to grow your business. This section looks at three important areas: using Industry 4.0 technologies, focusing on sustainability, and entering global markets. These ideas can help your business succeed and grow for the future.

Using Industry 4.0 and Smart Manufacturing

Industry 4.0 is changing how factories work. It uses smart tools to make production faster and better. Think of it as turning your factory into a high-tech operation.

Here are some key technologies in Industry 4.0:

Technology | What It Does | Why It Matters |

|---|---|---|

Internet of Things | Links machines to share and collect data. | Helps make smarter decisions. |

Artificial Intelligence | Handles tough tasks and gives useful insights. | Makes work more efficient. |

Big Data Analytics | Studies large data for better predictions. | Helps analyze information quickly. |

Machine Monitoring | Checks how machines are working. | Reduces downtime and improves output. |

These tools bring real benefits. For example, smart factories can increase value by 30%. They also use 5% less energy and cut CO2 emissions by 7%. This makes your factory greener and more efficient.

Metric | Improvement Range | Average Improvement |

|---|---|---|

In-factory economic value | 5% to 30% | 15% |

Energy reduction impact | 10% to 25% | N/A |

Economic benefits from supply chains | 12% to 15% | N/A |

Projected reduction in manufacturing energy consumption | N/A | 5% (1,000 TBTU/year) |

Projected reduction in CO2 emissions | N/A | 7% (84 MMT/year) |

Market penetration of smart manufacturing | N/A | 9% to 10% over 10 years |

Tip: Start small. Try adding IoT or machine monitoring to one area first. Once it works, expand to other parts of your factory.

By using Industry 4.0, you can save money, work faster, and stay ahead of others.

Going Green with Sustainability

Sustainability is more than a trend—it’s essential. Customers and governments want businesses to be eco-friendly. Green manufacturing focuses on cutting waste, saving energy, and using safe materials.

Research shows that green practices improve environmental results. Sharing eco-friendly ideas and trying new methods can make a big difference.

Evidence Type | What It Shows |

|---|---|

Green Practices Impact | Green methods improve environmental performance in factories. |

Methodology | Data from 429 firms in five industries was studied. |

Key Findings | Green supply chains and innovation improve environmental results. |

Green manufacturing also meets safety and health rules. This helps the planet and builds trust with customers.

Callout: Going green isn’t just good for the Earth—it’s good for business. Companies that adopt green practices often save money and gain loyal customers.

To start, check your supply chain. Can you buy materials locally? Can you use less energy? Small steps can lead to big improvements.

Growing in Global Markets

Expanding to global markets opens new doors for growth. Selling in different regions can increase profits and reduce risks. But entering international markets takes careful planning.

Here are trends shaping global manufacturing:

Trend Type | What It Means |

|---|---|

Economic Impact | New technologies are changing productivity and creating winners and losers. |

Competitive Dynamics | Easier entry allows new competitors to join the market. |

Geopolitical Implications | Manufacturing is now tied to national security and trade policies. |

Investment Priorities | Money is shifting to resilient manufacturing with growth potential. |

Reshoring and Nearshoring | 83% of leaders are considering reshoring to avoid supply chain problems. |

Going global also means dealing with tariffs, rules, and cultural differences. But the benefits are worth it. You can reach more customers, rely less on local demand, and strengthen your business.

Tip: Work with experts who know the local market. They can help with rules and connect you to good suppliers.

If you’re ready to expand, research markets that fit your products. Look for areas with high demand and fewer competitors. With the right plan, global growth can bring big rewards.

Customization and On-Demand Production

Making products unique is changing how factories work. Customers want items made just for them. Businesses that offer this gain an advantage. It helps reduce waste and makes work more efficient.

Why Customization Matters

Customization isn’t just popular—it’s very important. Top companies that focus on it see better sales, faster work, and higher quality. Customers love personalized items, and businesses that adapt do well.

Here’s how customization helps different industries:

Industry | Success Metrics | Outcomes |

|---|---|---|

Automotive Manufacturer | Better product quality and happier customers with custom options. | |

Consumer Electronics | Shortened product design time by 40%. | Increased sales by 20% for special and custom items. |

Fashion Brand | Reduced extra inventory by 50%. | Made production greener and kept up with fashion trends. |

Benefits of On-Demand Production

On-demand production means making items only when ordered. This lowers storage costs and avoids making too much. Companies using this save 62% on costs by reducing downtime. It also helps grow profits and reach more customers.

Tip: Start small with limited-edition or custom items. This lets you try new ideas without big changes.

By using customization and on-demand production, you can meet customer needs, waste less, and earn more.

Leveraging Data Analytics and AI

Smart tools like data analytics and AI are changing factories. They help businesses make better choices, work faster, and stay ahead. These tools can predict repairs or improve production steps.

Real-World Applications of AI

Here’s how companies use AI to improve their work:

Predictive Maintenance at Ford: Digital models track machines and prevent breakdowns.

Quality Control at Foxconn: AI spots defects in electronics, ensuring great products.

Warehouse Management at BMW: Robots powered by AI organize inventory and fill orders.

Order Management with IBM Watson: Data analysis improves delivery and stock management.

Assembly Line Optimization at Volkswagen: AI uses sensor data to plan repairs and speed up work.

Benefits of Data Analytics

Data analytics shows how to improve your factory. It finds problems, predicts trends, and gives useful tips. For example, studying production data can show slow areas to fix before delays happen.

Callout: AI and data tools aren’t just for big companies. Smaller businesses can start with simple tools like repair prediction software.

Using these technologies helps you make better products, save money, and work smarter.

Strategic Partnerships and Collaboration

Working together helps businesses grow. Teaming up with the right partners opens new markets, shares resources, and speeds up innovation. Cooperation is now more important than competition.

Why Partnerships Matter

Partnerships let you share skills and tools. For example, working with a supplier can get you better materials for less money. Partnerships also help you sell in other countries by offering local knowledge.

How to Build Strong Partnerships

Here are tips for good teamwork:

Pick the Right Partner: Choose companies with similar goals and values.

Set Clear Goals: Agree on roles and plans from the start.

Stay in Touch: Talk often to solve problems quickly.

Share Benefits: Make sure both sides gain equally.

Tip: Try sourcing agents like Yansourcing. They connect you with trusted suppliers and simplify your supply chain.

Strong partnerships help you create new ideas, cut costs, and grow your business in manufacturing.

Yansourcing’s Role in Global Sourcing and Supply Chain Management

Finding products from around the world can be tricky. You might struggle to locate good suppliers, check quality, or manage shipping. That’s where Yansourcing helps. With over 10 years of experience, they make global sourcing and supply chain management easier. This lets you focus on growing your business.

Why Global Sourcing Matters

Global sourcing helps you find better materials and lower costs. It’s especially useful in manufacturing, where good suppliers are key. But working with international markets can be hard. Problems like language, culture, and rules can slow you down.

Yansourcing solves these problems for you. They connect you with trusted suppliers, handle deals, and manage shipping. Whether you need building materials or custom items, Yansourcing makes it simple.

Tip: Global sourcing isn’t just about saving money. It’s about building a strong supply chain for long-term success.

How Yansourcing Simplifies Supply Chain Management

Managing a supply chain has many steps. From finding suppliers to delivering goods, each part needs careful work. Yansourcing makes this easier by offering complete solutions made for your needs.

Here’s how Yansourcing helps your business:

Supplier Network: They work with trusted manufacturers to get quality products.

Quality Control: Products are checked carefully to meet your standards.

Logistics Expertise: They handle storage, shipping, and customs for you.

Customization Options: Need something special? Yansourcing helps create unique designs.

For example, if you need furniture or lighting for a project, Yansourcing ensures it arrives on time and meets your needs. Their supply chain skills save you time and reduce risks.

Real-World Impact: A Success Story

Here’s how Yansourcing helped Vietnam Mobile World make the BEFIT S1 smartwatch. The company wanted a product to compete with top brands like XiaoMi. Yansourcing managed everything—from finding a factory to ensuring quality and delivery.

The result? A high-quality smartwatch that met all needs. This shows how Yansourcing’s skills in sourcing and supply chain management can bring your ideas to life.

Callout: Yansourcing isn’t just a sourcing agent. They’re your partner in building a strong supply chain.

Why Choose Yansourcing?

Yansourcing focuses on your success. They give personal support at every step. Here’s what makes them special:

Feature | Benefit |

|---|---|

Trusted Supplier Network | Reliable manufacturers ensure consistent quality. |

End-to-End Solutions | They handle everything from sourcing to shipping. |

Cost Efficiency | Save money without losing quality. |

Customization Expertise | Get tailored solutions for your needs. |

By choosing Yansourcing, you get a partner who understands manufacturing and supply chains. They help you solve problems and find new opportunities.

What’s Next for You?

If you want to make sourcing easier and improve your supply chain, Yansourcing is ready to help. Visit their website to learn more and start your journey toward better global sourcing.

Reminder: The right sourcing partner can change your business. Don’t let supply chain problems slow you down.

Conclusion

Manufacturing businesses offer many ways to grow and succeed. You can use ideas like lean principles, Industry 4.0, or sustainability to improve your work. These methods can make your factory better and help it grow. Exciting options like customization, global markets, and smart tools bring new chances to expand.

Key Fact | What It Means |

|---|---|

Role in Economy | Manufacturing adds 16% to the world’s GDP, showing its value. |

Creating Jobs | New tech creates jobs needing advanced skills. |

Growth Potential | Green and custom production open new opportunities. |

To stay ahead, track metrics like OEE and KPIs. These show how well your factory works and where to improve. For example, Six Sigma lowers mistakes, and steady upgrades keep progress going strong.

Tip: Don’t let sourcing problems slow you down. Yansourcing makes global sourcing easy, saving you time and money.

Want to grow your business? Visit Yansourcing to learn how their help can improve your factory and find new ways to succeed.

FAQ

1. What is the best manufacturing strategy for small businesses?

The best strategy depends on your goals. For flexibility, batch manufacturing is a good choice. If you make custom items, job shop manufacturing works best. Use lean methods to cut waste and work smarter. Start small and grow as your business expands.

2. How can I reduce costs in my manufacturing business?

Save money by using lean manufacturing and automating simple tasks. Predictive maintenance helps avoid costly repairs. Working with sourcing agents like Yansourcing can get you quality materials at lower prices and simplify shipping.

3. Why is quality control important in manufacturing?

Quality control makes sure your products meet customer needs. It stops waste, catches mistakes early, and builds trust with buyers. Good quality checks save money and improve your company’s reputation.

4. How does Yansourcing help with global sourcing?

Yansourcing finds reliable suppliers, checks product quality, and handles shipping. They make the process easy, saving you time and money. Whether you need materials or custom items, Yansourcing ensures everything runs smoothly.

5. What is Industry 4.0, and why should I care?

Industry 4.0 uses smart tools like IoT and AI to improve factories. It helps you work faster, save money, and stay ahead of others. Start small with tools like machine monitoring to see quick improvements.