When you think about finding products, the term “supplier” is everywhere. But what does “supplier meaning” really encompass? It’s not just the person or company providing products. Suppliers are essential to your business. They influence costs, quality, and delivery times. Collaborating with reliable suppliers can enhance your strategies and boost profits.

If finding good suppliers is challenging or you seek improved sourcing, this article will assist you. Trusting suppliers isn’t just beneficial—it’s crucial for success.

Key Takeaways

Suppliers are important partners who affect price, quality, and timing. Picking good suppliers can help your business do well.

Check suppliers for trustworthiness, price, and product quality. Use a scorecard to rate them and choose wisely.

Work closely with suppliers by talking clearly and working together. This improves product quality and keeps the supply chain steady.

The Role of Suppliers in Product Sourcing

Understanding suppliers is important for your business success. Suppliers don’t just send products—they affect costs, quality, and stability. Let’s explore how they impact your business and why choosing the right ones matters.

How Suppliers Influence Cost and Profit Margins

Suppliers decide prices for materials, goods, and shipping. Working with affordable suppliers saves money and boosts profits.

But it’s not only about low prices. Smart sourcing helps you get bulk deals or better contracts. For example:

Transparency is the top vendor quality, says the 2022 Deloitte Global Outsourcing Survey.

Bulk buying and contract renegotiation are proven ways to save money.

Did you know good supply chains lower costs by 15%? Also, 79% of companies with great supply chains grow faster than others. That’s why smart supplier choices matter.

Data also helps here. About 81% of supply chain experts say analytics cut costs. By studying supplier data, you can find ways to save and improve deals.

The Impact of Suppliers on Product Quality

Suppliers directly affect how good your products are. Good materials make better products, while bad ones cause problems and unhappy customers.

Here’s how suppliers affect quality:

Metric | What It Means |

|---|---|

Counts defective items received. Fewer defects mean better quality. | |

On-time Delivery | Tracks if suppliers deliver on time. This keeps production smooth. |

RMA Rate | Shows the percentage of returned defective products. High rates mean poor quality. |

Bad materials raise costs. You’ll need more checks, and waste increases. Trusted suppliers reduce waste and make production easier.

For example, sharing supplier data improves their performance by 61%. This means fewer defects, faster deliveries, and happier customers.

Ensuring Supply Chain Stability with Reliable Suppliers

Reliable suppliers keep your supply chain steady. They deliver what you need, when you need it, without delays.

Look at Toyota. After an earthquake, they worked with more suppliers. This made them more flexible and ready for changes.

Procter & Gamble used safety stock and real-time tools during COVID-19. This helped them meet high demand.

Apple also uses many suppliers for key parts. When trade issues happened, they switched to other suppliers to avoid problems.

These examples show why reliable suppliers are vital. They don’t just deliver—they protect your business and help you handle challenges.

How to Evaluate and Select the Right Suppliers

Picking the right suppliers is very important for your business. A good supplier helps save money, keeps quality high, and avoids problems. But how do you find the best one? Let’s break it into easy steps.

Key Criteria for Supplier Evaluation (Reliability, Cost, and Quality)

Choosing a supplier isn’t just about price. Reliable suppliers deliver on time, keep quality steady, and communicate well. Here are key things to check:

Criteria | Description |

|---|---|

Location | How close they are and any benefits or challenges of their area. |

Employee capabilities | Their skills, focus on quality, and stable work history. |

Cost structure | Total costs, including making, managing, and shipping products. |

Quality capabilities | How well they meet your quality needs every time. |

Financial stability | Their money health, credit history, and ability to handle big orders. |

Environmental compliance | Following green rules and caring about sustainability. |

Management capability | Skills and experience of their leaders. |

Technological capability | Use of new tools and ideas to improve. |

Working conditions | Safety and comfort for their workers. |

Supplier network | How reliable their own suppliers are and any risks involved. |

A supplier scorecard can make this easier. It lets you rank suppliers by quality, cost, and delivery. This helps you choose wisely.

Tip: Don’t pick the cheapest option. Paying a bit more might mean better quality and reliability.

The Role of Geographical Location in Supplier Sourcing

Where a supplier is located matters a lot. It affects costs, delivery speed, and risks. Here’s why location is important:

Regional Regulations: Different places have unique trade rules, taxes, and customs. These can change costs and delivery times.

Logistics Efficiency: Nearby suppliers can lower shipping costs and avoid delays.

Geopolitical Risks: Problems like unstable governments or trade bans can hurt your supply chain.

For example, checking where your suppliers are can help save money. If one area has high shipping costs, you might switch to a cheaper region.

Pro Tip: Use location info to judge supplier performance. Suppliers in risky areas may not be good for urgent products.

Steps to Research and Vet Suppliers Effectively

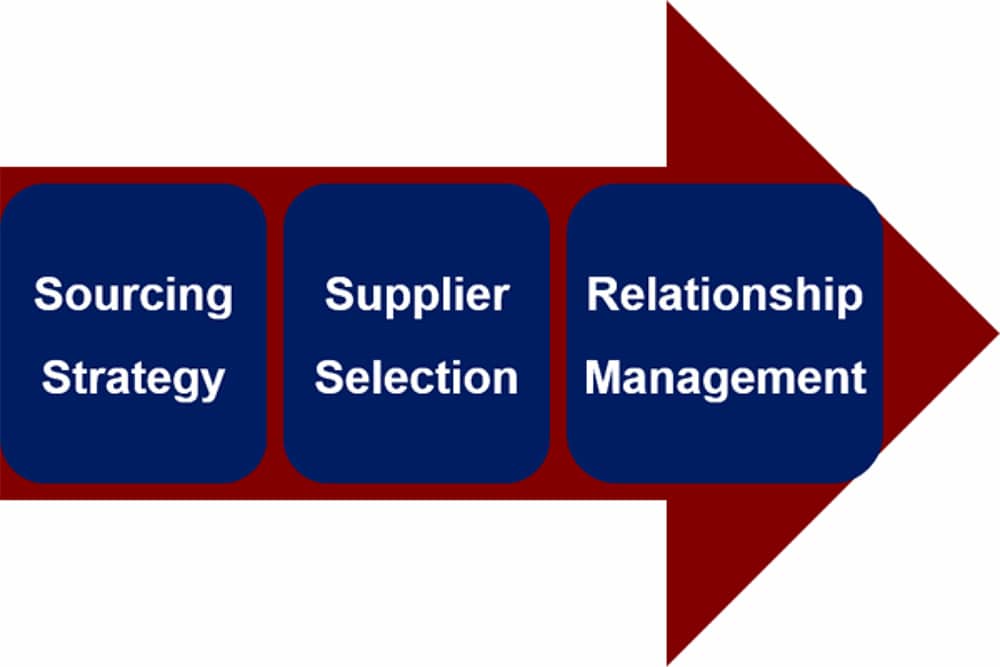

Finding a supplier is just the start. You need to check them carefully to make sure they fit your needs. Follow these steps to pick the right one:

Define Your Needs: Write down what you need, like product details, price, and quality.

Research Potential Suppliers: Look online, visit trade shows, or use sourcing agents like Yansourcing.

Request Documentation: Ask for certificates, quality records, and client references.

Conduct Audits: Check their factory, working conditions, and rule-following with audits.

Evaluate Performance Metrics: Review their defect rates, delivery history, and customer reviews.

Negotiate Terms: Talk about prices, payment plans, and delivery schedules to match your goals.

Start Small: Place a test order to check their reliability and product quality.

These steps help reduce risks and build a strong sourcing plan.

Reminder: A great supplier isn’t just someone you buy from—they’re a partner in your success. Take time to choose wisely.

Strategies for Building and Keeping Strong Supplier Relationships

Good supplier relationships are important for long-term success. Building these relationships takes effort, trust, and clear communication. Let’s look at ways to make them stronger.

Tips for Better Communication with Suppliers

Clear communication is key to working well with suppliers. Everyone needs to understand the goals and plans. Here are some tips to improve communication:

Set clear expectations: Share your goals, deadlines, and quality needs early.

Use technology: Tools like supplier software can track deliveries and quality.

Collaborate often: Share plans and forecasts to stay aligned.

Be open: Talk about problems honestly to find solutions together.

For example, working together on plans can improve delivery times. Checking delivery data can also help fix weak spots in your supplier system.

Checking Supplier Performance and Giving Feedback

Watching performance helps you find problems early. Use key metrics to check quality, delivery, and costs. Here are some helpful metrics:

Metric | What It Tracks |

|---|---|

How often suppliers meet deadlines. | |

The percentage of faulty products. | |

Lead Time | Time from placing an order to receiving it. |

Communication | How quickly suppliers reply to questions. |

Regular reviews and feedback help suppliers improve. Celebrate their successes to build trust. For example, giving clear improvement plans can lead to better results over time.

Working Together and Improving Continuously

Strong partnerships grow through teamwork. Solve problems and create new ideas with suppliers. Here’s how to encourage improvement:

Build strong bonds: Treat suppliers as partners, not just sellers.

Share useful info: Give data about market trends and customer needs.

Support innovation: Work together to lower costs or improve products.

Plan for challenges: Create strategies to handle disruptions together.

Toyota’s actions during the chip shortage are a good example. Their open relationships with suppliers helped them get important parts first. This kept production steady while others faced delays.

By focusing on teamwork, you can build a supply chain that’s strong, flexible, and ready for anything.

How Yansourcing Makes Finding Suppliers Easier

Finding a good supplier can be hard. You need someone reliable, affordable, and easy to work with. Yansourcing helps make this process simple. They have years of experience in sourcing and take away the stress.

Yansourcing’s Skills in Consumer Products

Yansourcing is great at finding products like bags, electronics, and pet supplies. They know the Chinese market well and connect you with trusted suppliers. Their team checks that every product meets your quality needs. Whether you want custom designs or large orders, Yansourcing can help.

For example, they’ve sourced items like PU leather bags and eco-friendly pet beds. These products meet market needs and help businesses stand out. With Yansourcing, you get high-quality goods that improve your brand.

Yansourcing’s Full Supplier Services

Yansourcing handles everything for you. They find suppliers, check their background, and manage logistics. Their services include:

Learning what products you need.

Checking suppliers with audits and reviews.

Talking about prices and contracts.

Making sure products are good and delivered on time.

They also offer storage and shipping help. This lets you focus on growing your business while Yansourcing handles the rest.

Stories of Success with Yansourcing

One success story is their work with LRG International. They helped create Bluetooth speakers for different markets. Even with small orders and design changes, Yansourcing delivered great products on time. This shows how Yansourcing turns tough sourcing tasks into wins.

When you choose Yansourcing, you’re not just hiring a sourcing agent. You’re getting a partner who cares about your success.

Conclusion

A supplier is more than just someone who sells products. They are key partners that affect costs, quality, and stability. Picking the right suppliers and building good relationships can change your business for the better.

Here’s why suppliers are important:

Benefit Type | Key Advantages |

|---|---|

Lower Costs | Save money with bulk buying and smart processes. |

Better Quality | Work closely to get reliable, high-quality products. |

New Ideas | Team up to create fresh solutions and improvements. |

Risk Control | Use multiple suppliers to avoid supply chain problems. |

Quick Adaptation | Stay ready to handle market changes fast. |

Good supplier relationships are not just about buying things. They are about building partnerships that:

Encourage teamwork and creativity.

Make sourcing a key part of your strategy.

If you want to improve how you find suppliers, Yansourcing can help. They make it easier, connect you with trusted suppliers, and keep your supply chain steady. Start improving your sourcing today!

FAQ

1. How do I find trustworthy suppliers?

Look on online directories or visit trade shows. You can also use sourcing agents like Yansourcing. Check suppliers by doing audits, reviewing certifications, and placing small test orders.

2. What questions should I ask suppliers before working with them?

Ask about how much they can produce and their quality standards. Find out their delivery times and payment options. Also, request references and certifications to confirm they are dependable.

3. Why does a supplier’s location matter?

A supplier’s location changes shipping costs and delivery times. It also affects how they follow trade rules. Nearby suppliers can make shipping easier and faster.