A price-only quote is a trap. If your building materials RFQ doesn’t lock in compliance, testing, and packaging before a supplier bids, you’ll pay for it later in rework, retesting, and returns.

This guide shows exactly how to draft a single RFQ that works for both the United States and the European Union, with engineered wood/plywood as the running example and formaldehyde/VOC control as the single critical spec.

The dual-market compliance core

Selling into both the U.S. and EU? You can (and should) engineer one RFQ that covers both.

On the U.S. side, composite wood products (hardwood plywood, particleboard, MDF/thin MDF) must meet TSCA Title VI emission limits and related obligations (TPC certification, labeling, importer records).

The EPA program page outlines scope and obligations for panels and finished goods; see the overview in the EPA’s Formaldehyde Emission Standards for Composite Wood Products program page for context and links to compliance guides: see the consolidated overview on the EPA’s program page in 2018–2024 updates via the EPA formaldehyde standards program page.

For a quick alignment check between state and federal rules, the Air Resources Board provides a side-by-side of labeling and recordkeeping differences in its January 2024 update: see the CARB vs EPA comparison table (2024).

On the EU side, EN 13986 governs wood-based panels used in construction; the formaldehyde emission class E1 is the recognized benchmark when tested via chamber methods like EN 717-1. The standard overviews are available in the EN 13986 catalog summary and EN 717-1 catalog.

A note on terminology: in the EU, “E0” and “super E0” are market terms, not official EN classes. Keep E1 as the legal reference. If you want a tighter internal target for your project, state it as a buyer specification, not as an official class.

U.S. emission limits that your RFQ can cite as pass criteria (measured by ASTM E1333 or an approved equivalent) include:

| Composite wood product | TSCA Title VI limit (ppm) |

|---|---|

| Hardwood plywood (veneer/composite core) | 0.05 |

| Particleboard | 0.09 |

| MDF | 0.11 |

| Thin MDF (≤8 mm) | 0.13 |

These limits reflect the federal regulation structure referenced in the EPA program materials noted above. If you’re specifying plywood, name which category applies (e.g., HWPW-VC).

Make formaldehyde/VOC the single critical spec

Why anchor your building materials RFQ on formaldehyde/VOC? Because it’s the failure mode most likely to derail customs clearance, marketplace compliance, and project handover—far more costly than a thickness tolerance dispute.

For the U.S., require panels to meet TSCA Title VI limits with certification by an EPA-recognized Third-Party Certifier (TPC), quarterly certification testing, and appropriate labeling and records; lab reports should use ASTM E1333 (large chamber) or ASTM D6007 (small chamber) only when the producer maintains a valid correlation to E1333 as allowed under 40 CFR Part 770, as outlined on the EPA formaldehyde standards program page and confirmed by the EPA recognized TPCs registry.

For the EU, specify EN 13986 E1 with EN 717-1 as the reference method; if your project needs a tighter internal target, write it explicitly alongside E1 and avoid treating “E0/super E0” as official classes; see the EN 717-1 catalog and EN 13986 catalog summary.

Non-negotiables your building materials RFQ must include

Price won’t protect you. Gates will. Bake these gates into the quote request—not as suggestions, but as conditions of doing business.

- Golden sample: approve a pre-production sample and retain it as the single point of truth for later inspections.

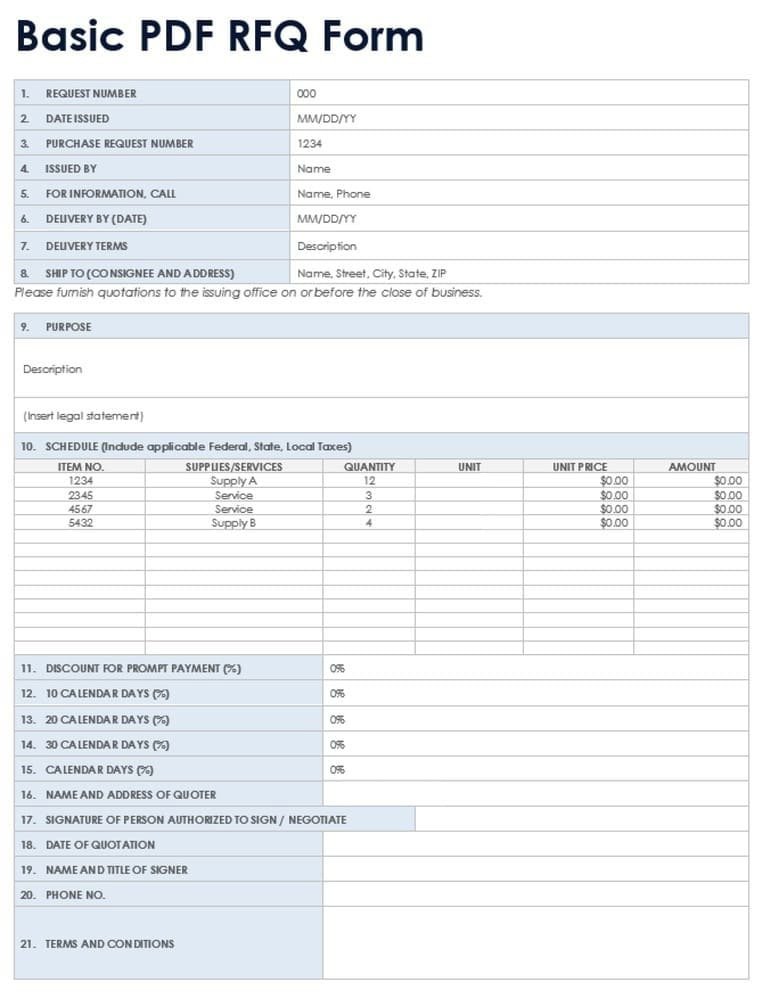

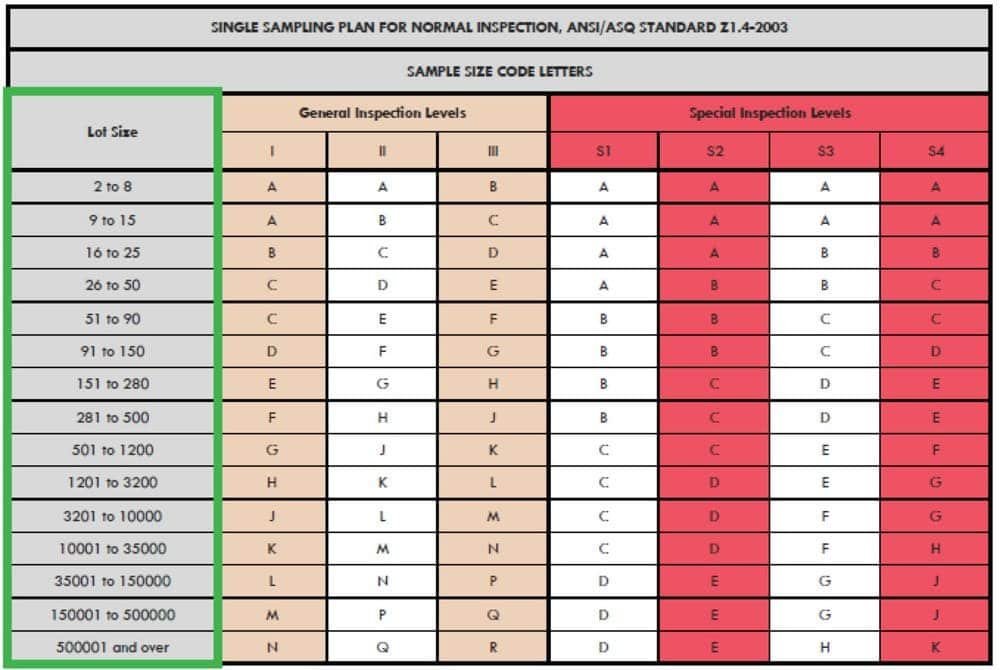

- Pre-shipment inspection: apply AQL 0.0% (critical), 2.5% (major), 4.0% (minor) at General Inspection Level II; not pass = not ship. For how acceptance sampling plans are interpreted, see the ASQ Z1.4 overview.

- Third-party testing before dispatch: testing to named standards at SGS/Intertek/TÜV/BV or a buyer-approved equivalent; failure = no shipment.

- Rework/re-inspection costs: allocate responsibility up front.

Copy-ready clause language you can paste into your RFQ:

Non-Negotiable Quality & Compliance Gates

1) Pre-production sample approval: Supplier to submit production-intent sample(s). Upon approval, Buyer and Supplier will retain an identical “Golden Sample” as the sole reference for visual, dimensional, and performance attributes. Any deviation requires prior written approval.

2) Pre-shipment inspection (PSI): Buyer or Buyer’s agent will conduct PSI to ISO 2859-1/ANSI/ASQ Z1.4, General Inspection Level II, AQLs: Critical 0.0%, Major 2.5%, Minor 4.0%. Ac/Re per standard tables. PSI failure = no shipment. Supplier bears costs of rework, corrective actions, and re-inspection when PSI fails due to Supplier-attributable causes.

3) Third-party lab testing before dispatch: Supplier agrees to complete pre-dispatch testing at SGS/Intertek/TÜV/BV or Buyer-approved lab. Pass criteria and methods:

• U.S.: TSCA Title VI limits (HWPW ≤0.05 ppm; PB ≤0.09 ppm; MDF ≤0.11 ppm; thin MDF ≤0.13 ppm) via ASTM E1333 or D6007 with valid E1333 correlation. TPC certification required.

• EU: EN 13986 E1 via EN 717-1 chamber method. If Buyer specifies tighter internal targets, they apply in addition to E1.

Reports must show lab identity/accreditation, method/standard, product description, and batch/lot traceability that links to shipment documents. Test failure = no shipment.

4) Export packaging for ocean freight: Moisture protection (aluminum barrier + desiccant or moisture-barrier bags), pallet specs, carton markings and scannable barcodes, stacking limits on carton and pallet labels. Optional: ISTA 1/2 Series drop/stack/vibration per Buyer instruction. Supplier to provide container loading plan and evidence package (loading photos, container seal number, carton marks) prior to shipment release.

5) ISPM 15 pallets: Any solid-wood pallets/crates/dunnage must be ISPM 15 treated and bear legible IPPC marks on two opposite sides (HT or other NPPO-approved treatment). Processed-wood or plastic pallets are acceptable and exempt from ISPM 15.

Documents you must require (and how they connect)

Most compliance failures trace back to missing or mismatched documents. Require product-level attestations and shipment-level traceability—and state retention periods.

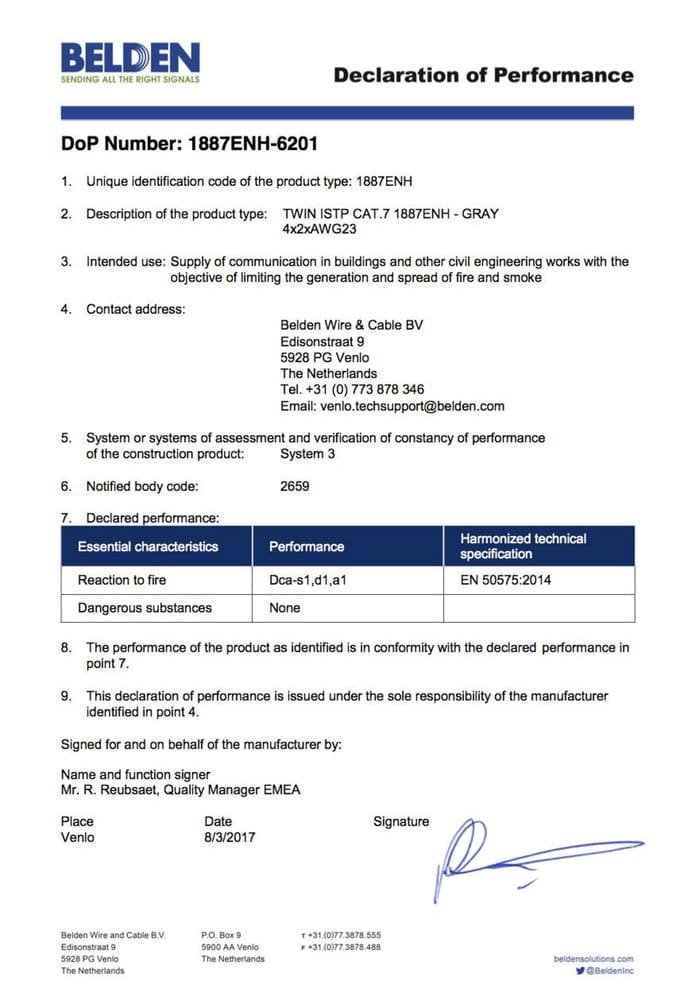

Explain to suppliers that EU construction products require a Declaration of Performance (DoP) and CE marking under EN 13986 when placed on the EU market, with a manufacturer’s Declaration of Conformity used as the legal attestation where applicable.

The European Commission’s overview of DoP and CE marking under the CPR is a helpful reference.

For the U.S., import entries require TSCA Section 13 certification in CBP ACE indicating compliance; the EPA TSCA Title VI import certification webinar (2019) explains process and codes.

Maintain test evidence tying the shipment to a recent third-party report (latest batch or last 12 months) with lab identity, method (ASTM E1333/D6007 or EN 717-1), standard number, product description, and batch/lot traceability that maps to labels and shipping paperwork.

For U.S.-bound goods, confirm the panel producer’s TPC appears on the EPA recognized TPCs registry.

Export packaging that survives the ocean

Container environments punish wood products.

Spell out moisture barriers, pallet specs, and verifiable evidence.

Use aluminum barrier film with desiccant or moisture-barrier bags; mark stacking limits clearly on cartons and pallets; add corner/edge protection to keep faces clean.

When you need transit validation, select a procedure from the ISTA test procedures page—Series 1 for integrity screening, or Series 2 for partial simulation with elements like compression and random vibration.

And if any solid wood pallets or wood packaging will travel internationally, they must be treated and marked per ISPM 15; the U.S. enforcement perspective is summarized in CBP guidance referencing ISPM 15 marks.

Processed-wood pallets (plywood, OSB, PB, MDF) and plastic pallets are generally exempt; if you use solid wood, require legible IPPC marks on two opposite sides.

Copy-paste example: RFQ section for engineered wood/plywood

Use this example block as the backbone of your dual-market RFQ.

RFQ: Engineered Wood / Plywood for US + EU Markets

1) Product scope: Hardwood plywood (veneer core) for interior use; finish-ready faces; moisture content 8–12% at shipment; buyer may add mold/mildew resistance requirements for hospitality projects.

2) Compliance framework (dual-market):

• U.S.: TSCA Title VI (40 CFR Part 770) compliance required. Panel producer must be certified by an EPA-recognized Third-Party Certifier (TPC). Emission limits: HWPW ≤0.05 ppm via ASTM E1333 or ASTM D6007 with valid E1333 correlation. Finished goods and panels must carry compliant labels; supplier to maintain and share records upon request.

• EU: EN 13986 E1 class via EN 717-1 chamber method. If Buyer specifies a tighter internal emission target, Supplier must meet both E1 and the Buyer target. “E0/super E0” may be stated as marketing descriptors only, not as official classes.

3) Documentary requirements with bid:

• Manufacturer’s Declaration of Conformity (where applicable) and, for EU shipments, Declaration of Performance (DoP) + CE marking evidence under EN 13986.

• Third-party lab test report: latest batch or last 12 months; includes lab identity/accreditation, method/standard, product description, and batch/lot identifiers linkable to shipment labels.

• TPC evidence (U.S.): current TPC certificate or listing showing the panel producer is certified under TSCA Title VI.

4) Non-negotiable gates:

• Golden Sample retained by both parties as visual/dimensional standard.

• Pre-shipment inspection to ISO 2859-1/ANSI/ASQ Z1.4, General II; AQLs: Critical 0.0%, Major 2.5%, Minor 4.0%; PSI failure = no shipment. Supplier bears rework and re-inspection costs when failure is Supplier-attributable.

• Pre-dispatch testing at SGS/Intertek/TÜV/BV or Buyer-approved lab to pass criteria in Section 2; test failure = no shipment.

5) Packaging & logistics:

• Ocean-grade moisture protection (aluminum barrier + desiccant or moisture-barrier bags), corner/edge protectors, palletization per Buyer spec, visible stacking-limit labels.

• Optional ISTA 1/2 Series testing as specified by Buyer.

• ISPM 15: any solid-wood pallets/crates/dunnage must be ISPM 15 treated and marked (two opposite sides). Processed-wood or plastic pallets acceptable and ISPM 15-exempt.

• Evidence package required before shipment release: container loading photos, container number & seal number, carton/pallet marks, barcode label samples.

6) Commercial terms:

• Pricing must include all compliance, testing, inspection, and packaging requirements herein. Deviations must be quoted as line items and pre-approved in writing.

Supplier response checklist

Use this as your acceptance screen before you award the PO. If any line is missing or mismatched, press pause.

Ensure the compliance proof for EU shipments includes DoP + CE evidence under EN 13986 and that U.S. shipments include TSCA Title VI statements and labels matching the goods, with TPC certification proof for the listed panel producer.

Confirm the lab test report’s identity, method, standard, and batch/lot traceability map to product labels, packing list, and invoice, and that methods align to scope (ASTM E1333/D6007 or EN 717-1 as specified).

Verify the factory accepts PSI at General II with AQL 0.0/2.5/4.0 and acknowledges “not pass = not ship” plus rework/re-inspection cost allocation.

Finally, lock down the packaging plan—moisture barrier, pallet spec, stacking limits, barcode samples, and ISPM 15 plan (or processed-wood/plastic pallets)—and obtain agreement to provide loading photos, seal number, and mark samples before shipment release.

Micro-example: coordinating the gates end to end

Disclosure: Yansourcing is our product.

In practice, a sourcing agent can help enforce the RFQ by:

- verifying the panel producer’s listing on the EPA’s recognized TPC registry,

- booking a pre-shipment AQL inspection to General II at 0.0/2.5/4.0,

- coordinating a pre-dispatch lab test to the specified method at SGS/Intertek/TÜV/BV, and

- confirming pallet choices meet ISPM 15 (or documenting processed-wood/plastic alternatives).

Buyers can also manage each step directly by engaging independent labs and inspection firms.

Mini-cases: avoidable failures and the clause that fixes them

The missing correlation: a supplier submitted ASTM D6007 results with no correlation to E1333. U.S. customs flagged the entry, and the importer had to retest. The fix: RFQ clause requiring D6007 only with valid E1333 correlation and batch/lot traceability.

The laminated trap: a hospitality headboard program used laminated panels. The producer wasn’t treating themselves as a “panel producer” under U.S. rules post-March 2024. The fix: RFQ compliance scope that calls out laminated products and requires TPC scope confirmation or exemption documentation.

The soggy stack: pallets arrived with warped faces after an ocean voyage. No barrier film, and stacking limits weren’t labeled. The fix: packaging clause requiring aluminum barrier + desiccant, stacking-limit labels, and an evidence pack with loading photos before shipment release.

Quick definitions buyers ask for

AQL: A standardized acceptance sampling system (ISO 2859-1/ANSI/ASQ Z1.4) that sets defect acceptance thresholds and sample sizes. Typical consumer setups use General II with 0.0% critical, 2.5% major, 4.0% minor. See the ASQ Z1.4 overview for context.

TSCA Title VI label: U.S. labels on composite wood panels and finished goods that indicate compliance and trace back to a certified panel producer and EPA-recognized TPC; document retention for importers is generally three years under federal rules described on the EPA formaldehyde standards program page.

E1: The EU formaldehyde emission class for wood-based panels, verified by methods such as EN 717-1 under EN 13986 for construction uses. Overviews appear in the EN 13986 catalog summary and EN 717-1 catalog.

DoC vs DoP: A Declaration of Conformity (DoC) is a legal attestation by the manufacturer of compliance with applicable legislation; under the EU Construction Products Regulation, wood-based panels placed on the EU market require a Declaration of Performance (DoP) and CE marking that declare performance against EN 13986; see the Commission’s DoP and CE marking overview.

Next steps to finalize your building materials RFQ

Start from the example block above and tailor the product scope, pass criteria, and packaging details to your distribution environment and end markets.

For the U.S., confirm the panel producer appears on the EPA’s recognized TPC registry before award; for the EU, align your DoP/CE and labeling flow with EN 13986.

Lock the gates into the RFQ (golden sample, AQL, pre-dispatch testing, ISPM 15) and make “failure = no shipment” explicit—then require the evidence package before releasing cargo.

Finally, brief your team and suppliers. Share the checklist and agree on document naming and label formats so batch/lot identifiers match across reports, labels, and invoices.

That’s how you turn a quote into a compliant shipment.